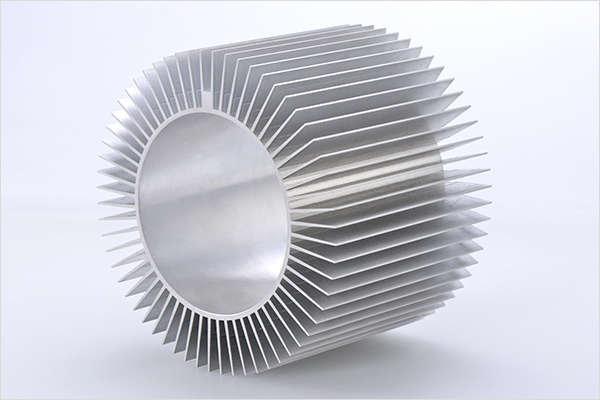

Mastars is a global manufacturer of plastic and metal products from prototype design to mass production for many Fortune 500 enterprises. The production process includes CNC processing, vacuum casting, 3D printing, sheet metal, forging, extrusion, etc.

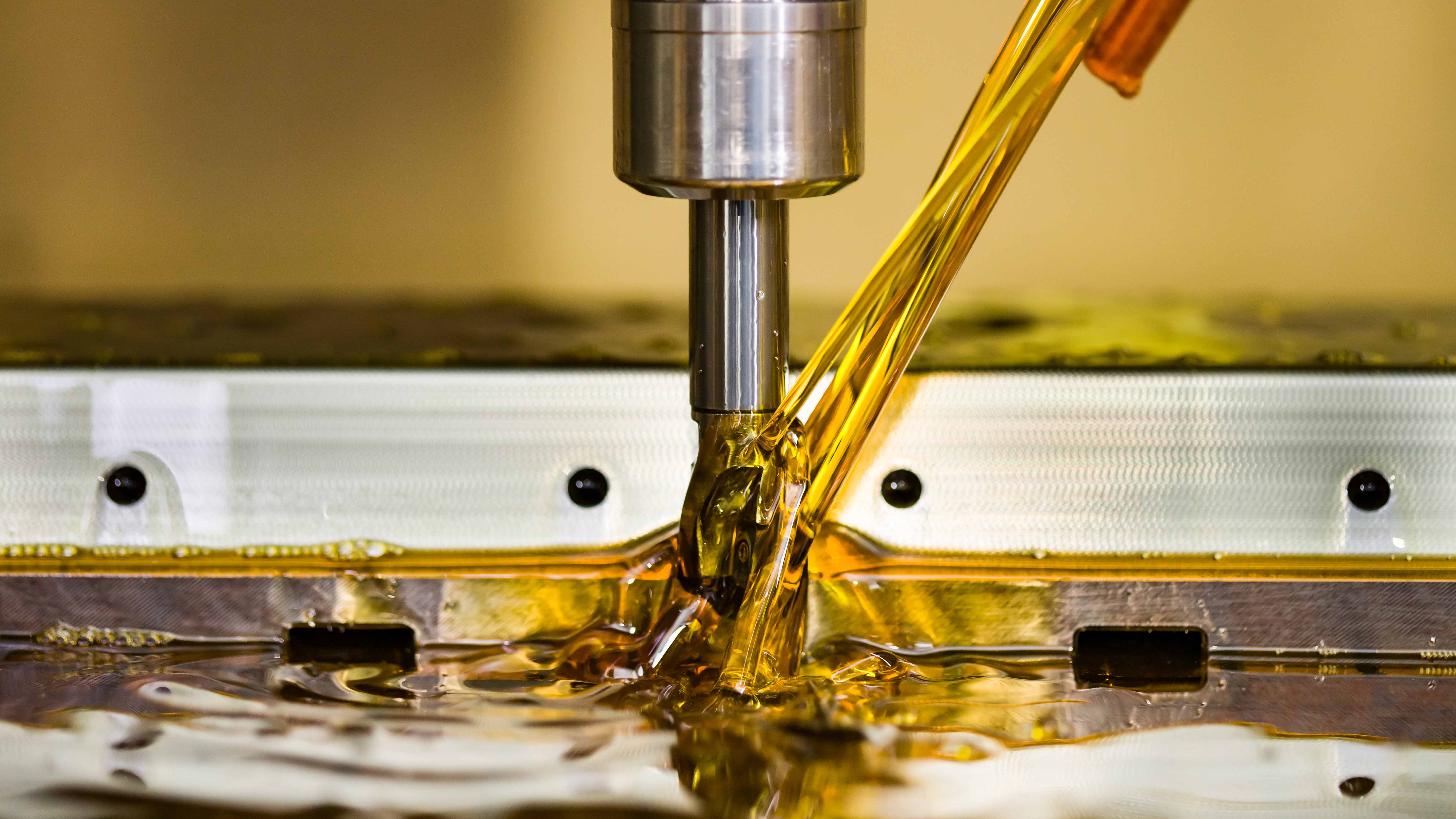

The forging process of stainless steel has the following characteristics:

(1) Poor thermal conductivity. Stainless steel contains a lot of alloy elements such as chromium, nickel, manganese and titanium, so its thermal conductivity is poor. The more alloying elements, the worse the thermal conductivity. Below 800 ℃, its thermal conductivity is about 20% lower than that of ordinary carbon steel and alloy steel? The thermal conductivity of 50% at high temperature is similar to that of magnetic steel and alloy steel. Strictly control the heating temperature and heating speed during heating.(5) Large size shrinkage. The main reason is that the linear expansion coefficient of austenitic steel is large. Therefore, when the forging is finally formed, the size of the forging should be controlled according to the large shrinkage rate to avoid scrapping due to insufficient size after cooling.

Mastars' rapid prototyping service can provide various forging prototyping services according to customers' needs, verify your designed, provide fast, efficient and cost-effective services, and lay the foundation for future mass production of your products.

Mastars Industries CO., LTD

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210690

Mobile: +86 181 0029 4997

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China