Advantages and disadvantages of plastic extrusion molding

Mastars employ proven prototype technologies(CNC machining, Vacuum casting, 3D printing etc.), to take new concept or design and bring it to life, develop and evaluate new products quickly, economically and with less risk. With lesson learn from prototyping, we provide considered and proactive tooling design/build and mass production processing, from injection molding, die casting, CNC machining to final assembly as full one-stop solution.

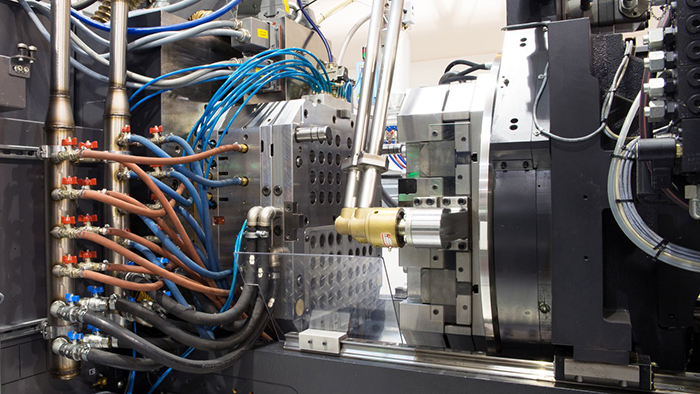

Extrusion molding process

Extrusion Molding is a molding method in which the heated and melted polymer material is forced to pass through the head die and form a continuous profile with a constant cross-section by means of the extrusion action of a screw or a plunger. The extrusion molding process mainly includes the processes of feeding, melting and plasticizing, extrusion molding, shaping and cooling.

The extrusion process can be divided into two stages: the first stage is to plasticize the solid plastic (that is, to become a viscous fluid) and make it through a special-shaped mouth model under pressure to become a continuous shape with a cross-section similar to the shape of the mouth model. The second stage is to use an appropriate method to make the extruded continuum lose its plastic state and become a solid to obtain the desired product.

Advantages of extrusion molding:

1) The structure of the molding equipment is relatively simple, and the equipment investment is low.

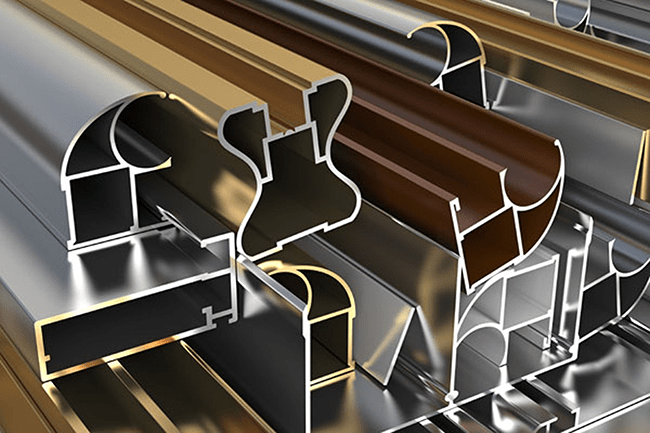

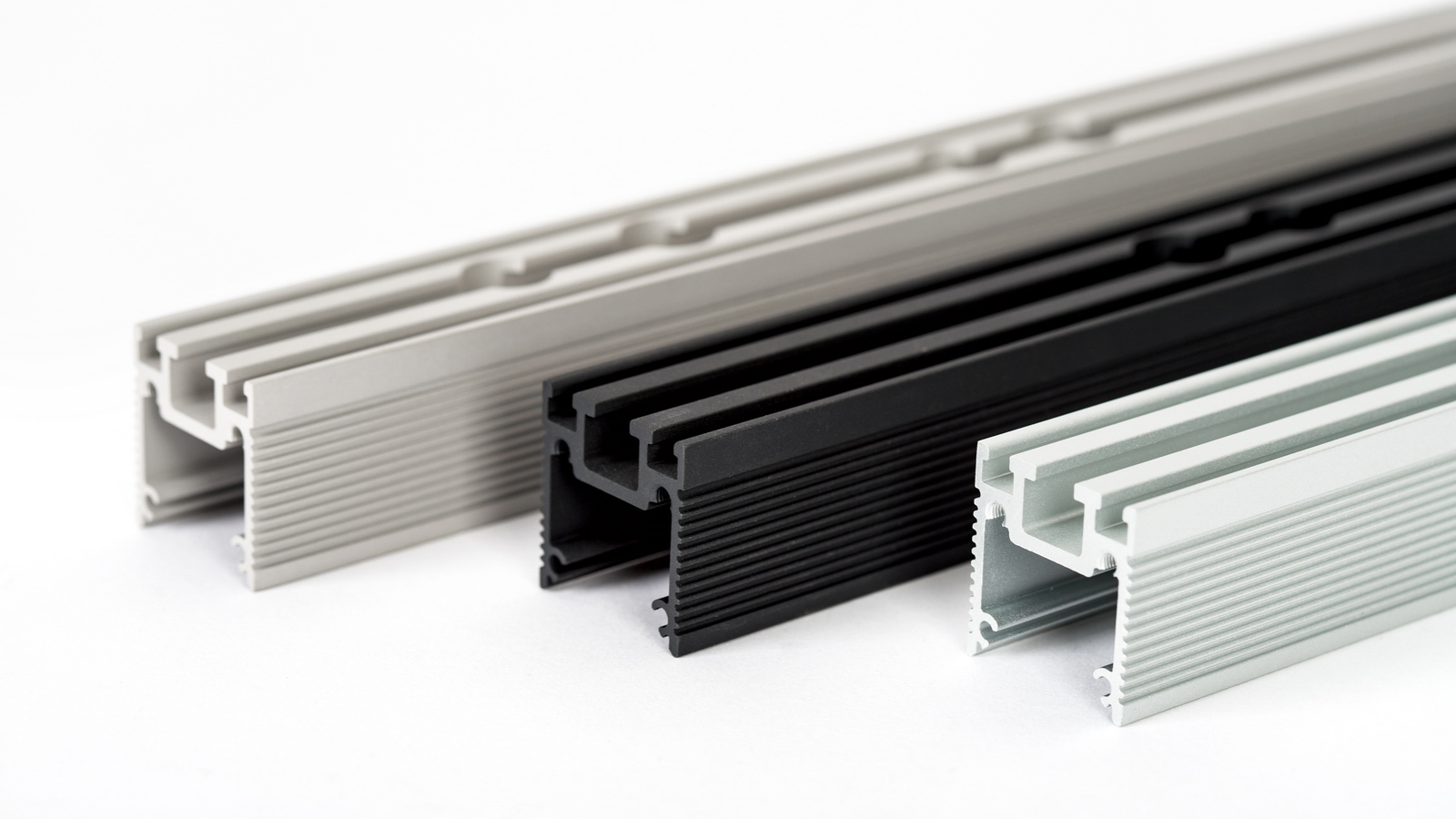

2) Continuous production

Pipes, plates, bars, profiles, films, cables, monofilaments and other products of any length can be produced as required.

3) Wide application range.

4) High production efficiency The single output of the extruder is relatively high.

5) One machine with multiple uses One extruder can process a variety of materials and products.

6) The processed material does not undergo metallographic change, and the molding process can usually be carried out at a lower temperature with less energy consumption.

7) It is suitable for producing products with large differences in cross-sectional size, and has strong adaptability to the cross-sectional size of products.

8) The control system is relatively simple, and the process control is very flexible. By controlling the extrusion stroke, it is possible to obtain products of different sizes by using the same pair of molds.

9) In the case of small production batches, it can greatly reduce production costs and so on.

Disadvantages of extrusion molding:

1) The microstructure and properties of the products produced by the extrusion molding process are uneven. The flow is uneven during extrusion, resulting in uneven tissue properties between the surface layer and the center, head and tail of the extruded product.

2) The working conditions of extrusion die are poor, and the loss of die is large, which greatly affects the strength and service life of the die.

3) The production efficiency is low. Except for the developed continuous extrusion method, all conventional extrusion methods cannot achieve continuous production. Usually, the extrusion speed is much lower than the rolling speed, and the geometric waste loss of extrusion production is large, and the yield is low.

4) Only simple shapes of pipes and bars can be produced.