Mastars(provide

rapid cnc services,

rapid cnc machining,

rapid prototyping services.)Aluminum alloy wheels (and aluminum magnesium alloy wheels) have become the development trend in the future because of their lightweight, beautiful, good shock absorption and heat dissipation.

1、 Manufacturing method of aluminum alloy wheel hub

There are two main production processes of aluminum alloy hub:

Casting and

forging.

Compared with cast wheel hub, the metallographic structure of forged wheel hub is broken grain and forged structure, while the latter is dendritic grain and cast structure. Comparatively speaking, the die of forged wheels is much more expensive than casting, and it is also more difficult to open the die. However, the mechanical properties of forged wheels are 30%-50% higher, and the corresponding prices are much higher; From the point of view of production process, it is easier to mass produce by casting process, with low price and greater market demand.

In addition, some manufacturers use spinning method and welding assembly method to form. Spinning method is to cast a part of the wheel hub with corresponding allowance, and then use extrusion method to form, which requires special equipment and production line, which is rarely used in China; Generally, the welding assembly method only casts or forges the spokes, and the rims are rolled with formed coiled materials, and then the spokes and rims are welded into hubs, which can greatly reduce the weight and reduce the production cost. However, the process is complex, and Japan has been quite mature in this technology.

2、 Casting technology of aluminum alloy wheel hub

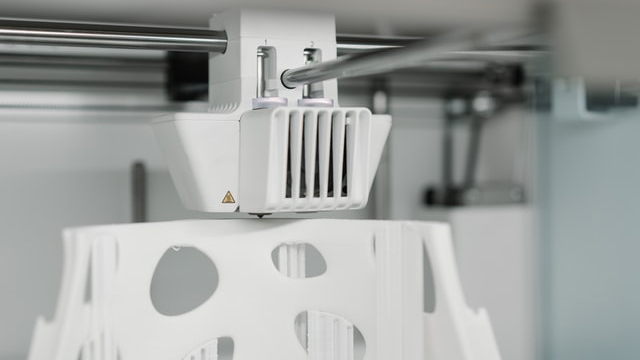

Casting wheel hub is the main production method used by most aluminum alloy wheel hub manufacturers.

The common casting methods include gravity casting, low pressure casting, squeeze casting and oxygen filled casting.

(1) Gravity casting

Gravity casting relies on the gravity of the molten aluminum itself to fill the mold. This method is relatively simple. The requirements for equipment conditions are not high, but the production stability is poor. The temperature field in the solidification process of molten aluminum is easily affected by external conditions, resulting in casting defects such as shrinkage porosity and shrinkage cavity. The labor intensity of workers is high, and the mechanical properties of products are poor, but the cost is low. Therefore, some enterprises are still using it in the production of small-size wheel hubs.

(2) Low pressure casting

At present, as the main production method of aluminum alloy hub, low-pressure casting is to fill the mold at a lower pressure (generally 20-60kpa). After the filling is completed, the pressure is maintained for a period of time, then the pressure is relieved, and the mold is opened for taking parts. This production method can mass produce high-quality wheel hubs. The solidification process of molten aluminum is carried out under pressure, so the product qualification rate and utilization rate of molten aluminum are high. The automation of low-pressure casting machine is high, the labor intensity of workers is relatively low, the production efficiency is high, and the cost is slightly higher than that of gravity casting.

(3) Squeeze casting

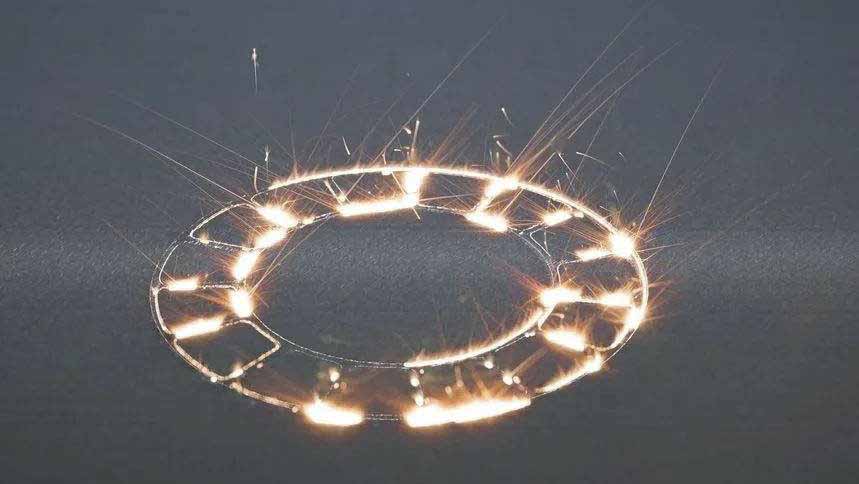

Also known as liquid forging, it is a process integrating the characteristics of casting and forging. It can be divided into multiple forms, such as composite squeeze casting, forward squeeze casting, double squeeze casting, etc. The common features are: in addition to the metal mold, there are also punch and mold ejector rod. Generally, about 7000n pressure should be applied on the punch for casting. The surface of the casting is smooth, the metallographic structure and various mechanical properties are close to those of the forging.

The process method is to use a hydraulic press to press the aluminum melt 5-l0 ℃ higher than the melting point of the alloy into the mold, and apply high pressure (P ≥ 100MPa) to the solidification melt at a speed of about 5mm/s. Through pressurized crystallization, the eutectic and dendrite are fully broken, and the aluminum hub with high density and no pores can be produced. The mechanical properties can be improved by more than l5%, but the technical difficulty and efficiency are low.

Mastars Industries CO., LTD

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210690

Mobile: +86 181 0029 4997

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China