Contents:

Mastars

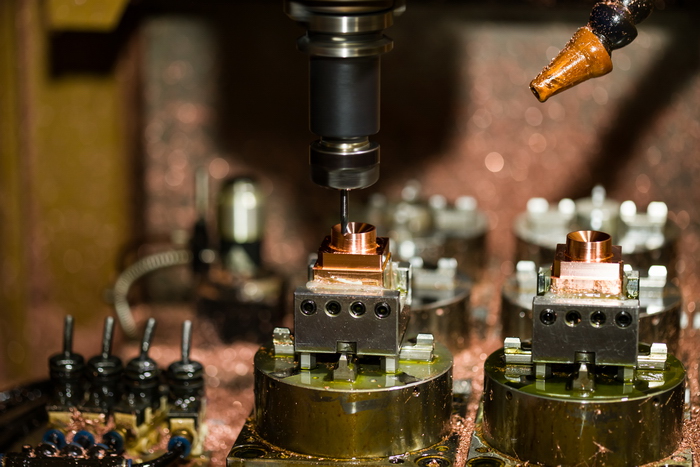

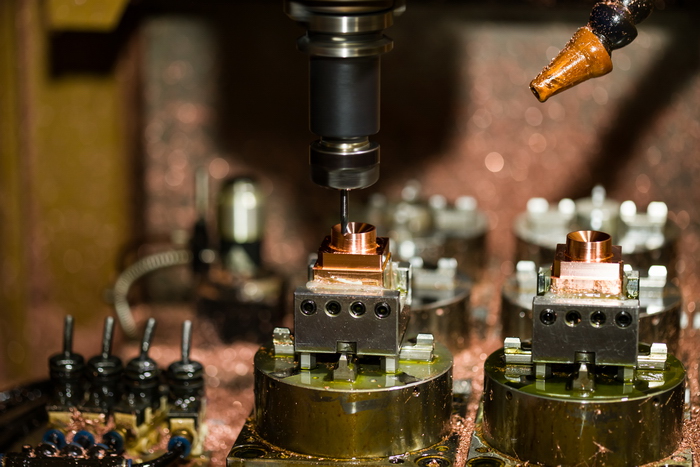

CNC machining

CNC milling

rapid prototyping

CNC machine

5-axis CNC machines

German HERMLE C22, C42, C62

Mastars is an expert in CNC machining, with more than 20 years of industry experience, making rapid prototypingfor major companies around the world, as well as mass production, if you have a demand for prototyping production, please contact us immediately, you will get the best quality products, and the best service.

CNC milling programming allows you to easily master other machining programs. For those who understand the milling program, it will not be difficult to master other types of processing.

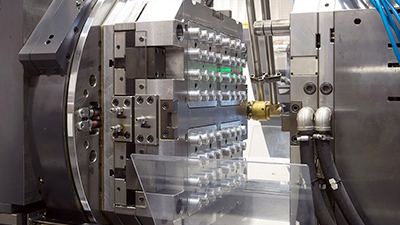

What is CNC Milling

Various types of processing can be performed on a CNC milling or CNC milling is a machining process, which uses computer-controlled and rotating multi-point cutting tools to gradually remove materials from the workpiece and produce customized parts or products. The process is suitable for machining various materials, such as metal, plastic and wood, and producing various customized parts and products.

Under the protection of precision CNC processing services, it can provide a variety of functions, including mechanical, chemical, electrical and thermal processing. CNC milling is a machining process, including drilling, turning and various other machining processes, which means that the material will be removed from the workpiece by mechanical means (such as the cutting tool action of the milling machine).

The main processing objects of NC milling machine

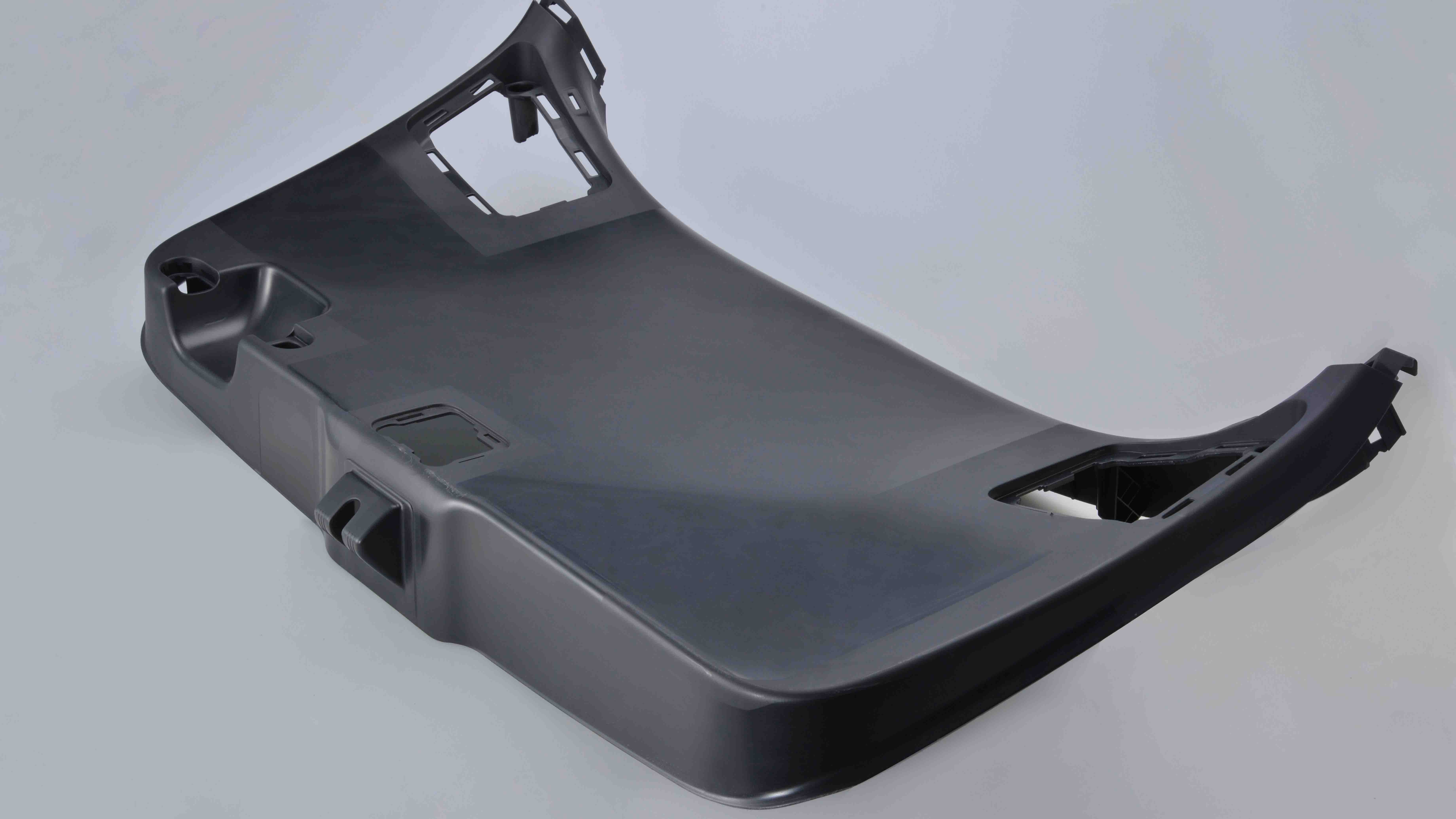

(1) Plane parts

The characteristics of plane parts are that the machined surface can be parallel to the horizontal plane, perpendicular to the horizontal plane, or at a fixed angle with the included angle of the horizontal plane; At present, the vast majority of parts processed on NC milling machines belong to plane parts. Plane parts are the simplest kind of parts in NC milling. Generally, they can be processed only by two-axis linkage or three-axis linkage of three-axis NC milling machine. In the process of machining, the machining surface is in surface contact with the cutter. End milling cutter or bull nose cutter can be used for rough and finish machining.

(2) Surface parts

The characteristic of curved surface parts is that the machining surface is a spatial curved surface. In the machining process, the machining surface is always in point contact with the milling cutter. Ball end milling cutter is often used for surface finishing.

Coordinate system of NC milling machine

In order to describe the position of points in plane and space, it is necessary to define a coordinate system to determine the direction and relative position. The coordinate system of NC machine tool adopts the right-hand Cartesian coordinate system. It stipulates that the positive directions of the three coordinate axes of rectangular coordinates x, y and Z are determined by the right-hand rule, and the positive directions of rotation axes a, B and C around each coordinate axis are determined by the right-hand spiral rule. CNC machining adopts the spatial three-dimensional coordinate system. The three-dimensional coordinate system adds a vertical axis on the basis of the two-dimensional plane coordinate system, which is usually called Z axis, which is the coordinate axis parallel to the machine tool spindle

Mastars

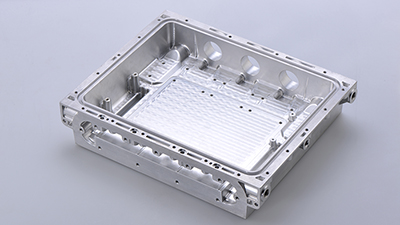

Mastars has the world's most advanced 5-axis CNC machines, German HERMLE C22, C42, C62 and other 5-axis machining centers, which can process any complex workpiece, and has unique advantages in the industrial manufacturing industry.

Mastars Industries CO., LTD

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210689

Fax: +86 755-8821 0685

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China