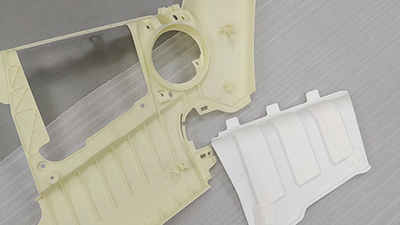

Everything About surface finish of plastic injection products

Surface textures and surface finish of any plastic injection product or part is extremely crucial when it comes to the overall look and feel and functionality of your product. When you talk about making plastic parts, additional processing may be needed before the completion of these parts. These processing requirements are needed so that the overall aesthetics and the appearance of the product can be improved and made as per the set industry standards. One of the many processes that are used for this purpose is the use of surface textures for mold surface. If you want a product with a good appearance surface finish is one of the most important factor.mastars provide rapid prototyping services and proactive tooling design/build and mass production processing, from injection molding, die casting, CNC machining to final assembly as full one-stop solution.

Surface finishes are also usually responsible for the overall performance of the plastic product. As such surface finishes are responsible for both aesthetic and functional aspects of your product. It is therefore important that you understand that

mold texture is a very crucial factor in determining the look, feel and the overall performance of your products. In this piece we will walk you through everything that you need to know about

surface molding .

Let us begin by understanding what Surface Finishes really are.

What is Surface Finish?

Surface finish is also known as surface topography or surface texture and is used to describe the nature of any surface. The surface finish is about defining the surface by allowing certain deviations in the surface and from being a true plane or a perfect surface. In simple terms it is the three dimensional form of a given product or solid. As such you will always find some kind of texture on every kind of surface.

The texture that is seen on the surface is formed as a result of some repeating patterns that are either regular or discreet. Texturing generally involves creating an array of certain recognizable patterns and these patterns in fact form the surface of these products. The various techniques that are followed in order to create these surface textures are known Surface Finish processes. The surface texture or surface finish are usually described using the following terms that are:

Lay – This is used to describe the general direction of the pattern. This is achieved using the various processes such as sanding, grinding, milling, etc.

Waviness – The next term that is generally used to describe a surface texture is waviness. This is achieved when a machine tool used to create the texture moves over a large area of the product. As such a waveform kind of texture is created on any piece of work due to the repetitive cyclical movement. This is usually achieved from a CNC machine as it is rolled over the product surface.

Roughness – You may get a product surface that is rough. This is either obtained by deliberate cutting to create a rough effect or can be result of chaotic, random cutting.

SPI Surface Finish Standards Explained

SPI is the Society of Plastics Industry, that is responsible for setting standards for the plastic industries in the US. The surface of any plastic product manufactured in the United States need to be made as per the SPI standards for surface finish. These standards are set to help determine and identify the aesthetic aspects of the plastic parts and materials used.

There are 12 different grades defined by SPI for surface finish of plastics. These 12 grades are further divided or categorized under four different categories. Each of these categories have a permissible extent or deviation from the perfect. These categories can further be categorized into:

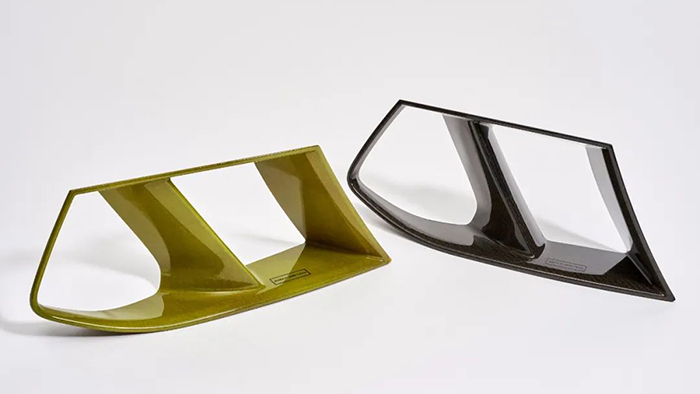

Shiny Finish

This category includes the top grades which are A-1, A-2, and A-3. These grades mean the product is supposed to have a high gloss finishing and an extremely hardened mold. The molds are made of steel which are buffed in order to lend a mirror luster using diamond powder in oil.

The surface finishing that is obtained in this category and the given grades are smooth, shiny and are usually expensive. The plastic products made in this grade include visors, optical parts or plastic mirrors.

Semi-Gloss Finish

The grades in these category include SPI grades that are next to the A grades, which are B-1, B-2, and B-3. This category provides the specification for products that need to be manufactured with semi-gloss surface finish. The semi-gloss finish is obtained using some hardened tools made from steel. These molds are polished using super-fine sandpaper. Some of the manufacturers also use emery cloth to manufacture these semi-gloss finish products. Plastic parts that are finished using this process do not show any molding defects.

Matte Finish

The products given a Matte finish include SPI grades C-1, C-2, and C-3. This is the category that specifies matte finish in the steel molds. The surfaces are polished using finely ground stone powder. The finish obtained in these grades do not show any machining or tool defects. They usually find their applications majorly using thermoset and die cast industrial parts. Matte finish is a pretty popular finish in most plastic products.

Textured Finish

The last type of finish is the textured finish that is categorized under SPI grades D-1, D-2, and D-3. Under this grade the molder is first used to give a fine finish using the stone powder. The molder is then used to do dry blasts using aluminum oxide. Glass beads are also used at times to lend a textured finish. Such type of finish gives a very good grip to the product. Textured finish is also good in terms of hiding any injection molding surface finish defects. The textured finished products are usually also sold well for their fingerprint and smudge free feature.

Now that we know about the various standards for surface finishes, let us now look at how the surface finish type affects the cost of the finish.

Conclusion

It is therefore important to keep in mind the various surface textures, finish types and standards that can be used as specifications of your parts. Use this piece as a guide to understand what works best for your requirement and how you can go about making the perfectly finished plastic parts.

Mastars Industries CO., LTD

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210689

Fax: +86 755-8821 0685

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China

surface molding mold texture