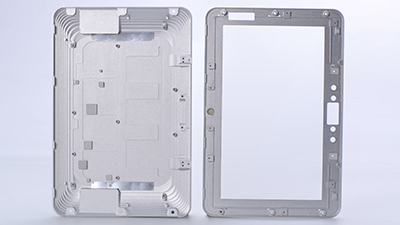

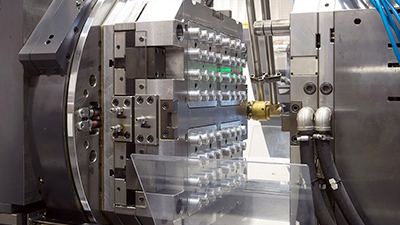

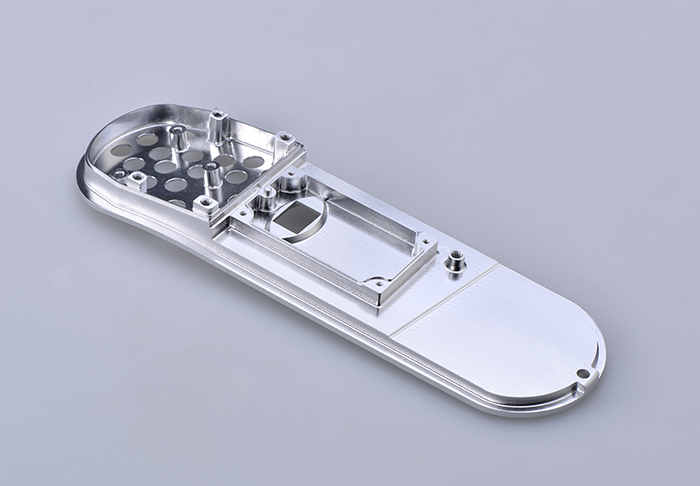

Mastars makes prototypings for hundreds of well-known companies around the world, and CNC is a commonly used processing technology. The CNC process has the advantages of good strength and high precision, and it is also suitable for mass production in the later stage. There are many materials available for CNC machining. When making a rapid prototyping, you can choose according to the properties of the material.

The most common metal materials are the following:

One of the disadvantages of 6061 Al is its poor corrosion resistance. It's also not as strong as other aluminum alloys for more demanding applications.

7075 Al is one of the aluminum alloys with the highest strength. Compared with 6061 Al, the processing performance of 7075 Al is slightly inferior, and because of its high strength, it is difficult to bend into complex shapes. The material is ideal for high-strength recreational equipment, automotive and aerospace frames.

Brass is common in plumbing fittings, home decor, and musical instruments, mainly because of its softness and ease of processing; due to its high polishability, brass is naturally resistant to seawater corrosion and is often used in cosmetic applications. It is a good material for home decoration, and will not spark when colliding with another metal, making it ideal for use in potentially explosive environments.

It is a ductile metal with excellent electrical conductivity, the surface is rose red, the electrical conductivity and thermal conductivity of copper are second only to silver, and it is widely used in the production of electrical and thermal conductivity equipment. Copper has good corrosion resistance and is often used in the chemical industry.

There are many varieties of stainless steel and gets its name from the addition of chromium that helps prevent oxidation (rusting). 303 stainless steel is a free-cutting stainless steel and is mainly used for products requiring free-cutting and high surface finish. It has good machinability, burning resistance and corrosion resistance. Compared with 304 stainless steel, its application is not so extensive. 303 stainless steel is mainly used in accessories such as stainless steel nuts and bolts, shafts and gears. However, it should not be applied to Marine grade fittings.

304 stainless steel is an excellent material choice for industrial buildings, automotive trim, kitchen accessories, tableware, water tanks and plumbing.

316 stainless steel is more resistant to corrosion due to the addition of molybdenum, so it is often considered a marine grade stainless steel. It's also tough and easy to be welded. 316 stainless steel is often used in construction, marine fittings, industrial plumbing, storage tanks, car decoration and kitchen utensils.