In modern industrial manufacturing, precision machining is becoming increasingly mature, and 5-axis CNC machine tools are more and more widely used in various fields. Whenever people encounter complex parts with irregular shapes, 5-axis machining technology is undoubtedly an important means to solve such problems. Mastars has German HERMLE C22, C42, C62 and other 5-axis machining centers, which have obvious advantages in the manufacture of various precision and complex industrial parts.

Today, let's learn about the advantages and disadvantages of 5-axis machining center.

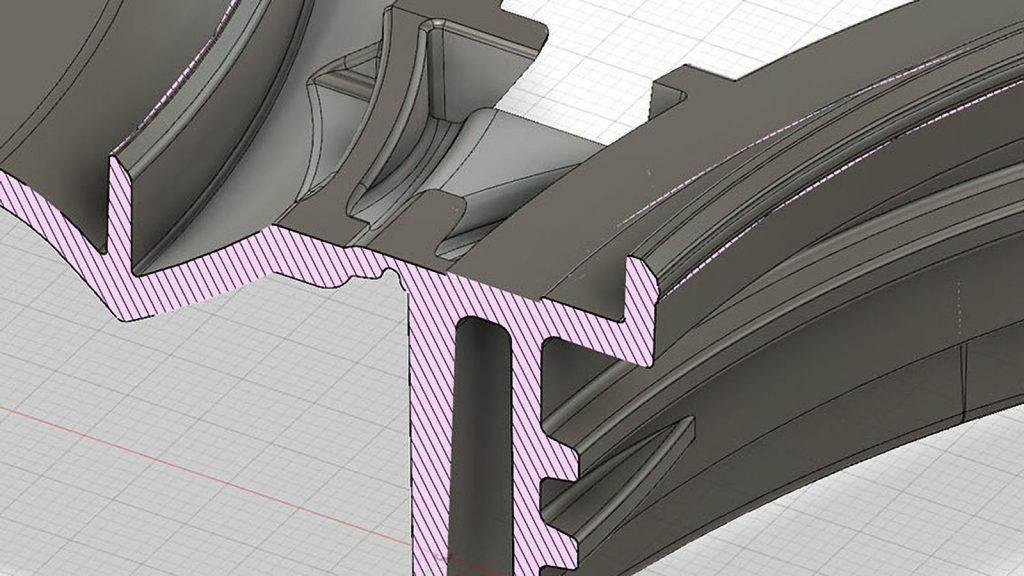

Traditional 3-axis CNC machine tools are more common in production, and there are several types such as vertical, horizontal and gantry. Common machining methods include end milling cutter end edge machining, side edge machining, profiling of ball head cutters and so on. However, no matter which type and method have a common feature, that is, the direction of the tool axis remains unchanged during the machining process, the machine tool can only through X, Y, Z three linear axis interpolation to achieve the tool movement in the space rectangular coordinate system.

Therefore, when manufacturing complex products, the disadvantages of low efficiency, poor surface quality and even inability to process of 3-axis machine tools are exposed.

Compared with 3-axis CNC machining equipment, 5-axis CNC machine tools have the following advantages:

1. Expand the scope of machining, and be able to machine parts with more complex shapes

2. Maintain the best cutting state of the tool and improve the cutting conditions

3. Improve the quality of the surface treatment, the smaller cutting improves the surface finish

4. Improve machining precision, no need to remove after one clamping

5. Effectively avoid tool interference

6. Reduce the number of clamping, complete five-sided processing in one clamping, and reduce the cost of workpiece fixtures

7. Shorten the production process cycle, improve production efficiency, and simplify production management

8. Shorten new product development cycle and reduce product delivery time

Disadvantages of 5-axis CNC machine tools :

1. The cost of the machine is high. Compared with ordinary three-axis machines, the price of 5-axis CNC milling machines is much higher. In addition, the maintenance cost of the machine is also high. Therefore, the total processing cost is high.

2. Due to the need for more complex machining programming, the requirements for the operator are high. 5-axis machining machines are more complex than other simple CNC machines, in order to run the machining efficiently and correctly, many parameters must be carefully calculated, and programming is much more complex than ordinary machine tools, so this will require an experienced programming engineer to complete, which will result in additional high costs.

Mastars:

Mastars has high-precision 3-axis and 5-axis CNC machines and EDM machines, which can guarantee the high precision and surface finish of mold processing. Mastars is an expert in CNC machining, with more than 20 years of industry experience, making

rapid prototyping for major companies around the world, as well as mass production, if you have a demand for prototyping production, please contact us immediately, you will get the best quality products, and the best service.

Mastars Industries CO., LTD

www.mastars.com

• Email: marketing@mastars.com

• Tel: +86 755-88210689

• Fax: +86 755-8821 0685

• Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China