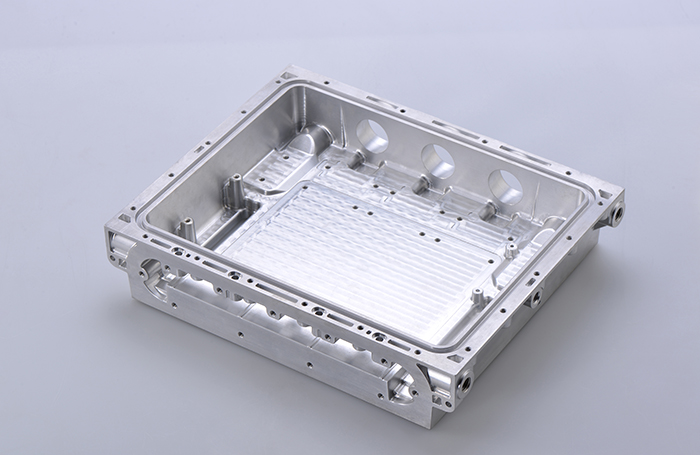

CNC machining is more and more widely used in key industries and key products. CNC machining plays a vital role in products with high precision requirements and difficult processing. In the rapid prototyping manufacturing service and industrial mass production, Mastars often adopts the CNC process. Mastars has the world's most advanced 5-axis CNC machines, German HERMLE C22, C42, C62 and other 5-axis machining centers, which can process any complex workpiece, and has unique advantages in the industrial manufacturing industry.

Let's take a look at the current demand for CNC machines in various industries.

The metallurgical equipment manufacturing industry focuses on the manufacture of complete sets of continuous casting and rolling equipment, requiring large-scale gantry milling machines, large-scale CNC lathes and other equipment. The production scale of ferrous metal smelting and rolling processing, non-ferrous metal smelting and rolling processing in China has grown steadily and rapidly in recent years. As China becomes a manufacturing powerhouse, the smelting industry still has a growing trend.

The engineering machinery manufacturing industry requires a large number of small and medium-sized CNC machines such as CNC lathes, medium-sized machining centers, CNC milling machines and gear processing machine tools.

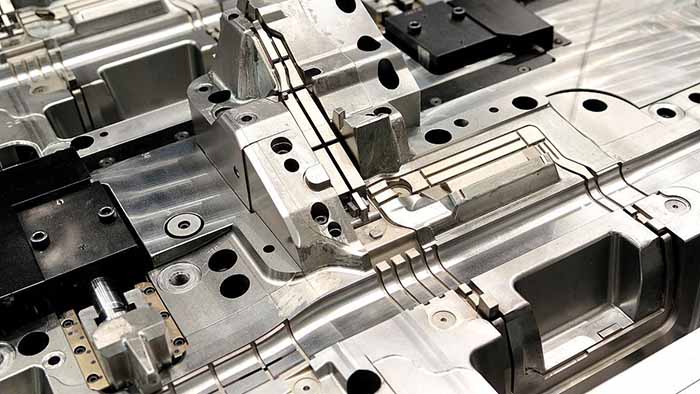

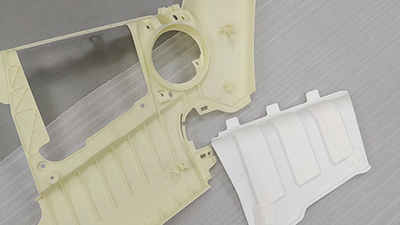

The mold manufacturing industry requires high-speed CNC milling machines, three-coordinate measuring machines, precision electrical machining machine tools, high-precision machining centers, and precision grinding machines.

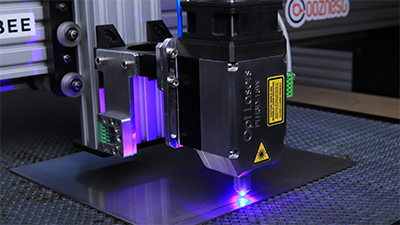

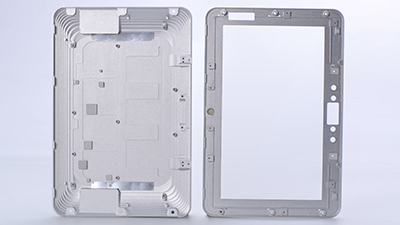

The electronic information equipment manufacturing industry requires a large number of small precision CNC machines , such as high-speed milling centers, high-speed machining centers, small precision lathes, small precision punches, CNC machines for precision and ultra-precision machining, and precision electrical machining machine tools.

In the aviation industry, the manufacture of aircraft wings, fuselage, tail, etc. and engine parts requires a large number of high-speed 5-axis machining centers, gantry mobile high-speed machining centers, precision CNC lathes, precision horizontal machining centers, multi-coordinate boring and milling centers, precision gear and thread machining CNC machine tools, etc.

The aerospace industry requires a large number of precision, high-speed, small and medium-sized CNC machines, such as precision CNC lathes and turning centers, vertical-horizontal conversion 5-axis machining centers, high-precision electrical processing machine tools, high-precision universal grinders and coordinate grinders.

The shipbuilding industry is in urgent need of heavy-duty and super-heavy gantry milling-boring machines and heavy-duty CNC floor-standing boring-milling machines for manufacturing diesel blocks, as well as large-scale CNC lathes and turning-milling centers, large-scale CNC gear grinding machines, crankshaft boring-milling machines, large-scale crankshaft turning-milling centers, and crankshaft grinding machines.

The automobile manufacturing industry is a large demand for machine tools, accounting for about 40% of the total consumption of machine tools. The automobile manufacturing industry requires a large number of high-efficiency, high-performance, special-purpose CNC machines and flexible production lines, such as flexible production lines based on high-speed horizontal machining centers for engine processing, and special CNC machine tools for crankshaft processing. The production of auto parts requires a large number of CNC lathes, vertical-horizontal machining centers, CNC high-efficiency grinders and CNC gear machining machine tools.

The weapons manufacturing industry requires a large number of reliable and stable CNC machines. Such as CNC lathes, vertical and horizontal machining centers, 5-axis machining centers, gantry boring and milling machines, boring and milling machining centers, gear processing machine tools, etc.

The power generation equipment manufacturing industry requires heavy-duty CNC gantry boring and milling machines, large floor boring and milling machines, large CNC lathes, special milling machines for blade root grooves and CNC machining machines for blade, etc. The power transmission and transformation equipment manufacturing industry requires CNC lathes, machining centers, CNC boring machines, etc.