Are you looking for products made of plastic? Or looking for new injection molding partners? In this article, we focus on the key issues to be considered when selecting molding suppliers.mastars is an experienced injection mold manufacturer. We provide

rapid cnc services,

rapid cnc machining,

rapid prototyping services.It enjoys a high reputation in terms of stability while maintaining a dynamic, supportive and flexible spirit.

Our team has more than 25 years of experience in mold manufacturing and injection molding. This article focuses on the key factors that must be considered when selecting injection molding suppliers.

Polymer selection

Polymer selection is an important part of injection molding, so when looking for suppliers, it is very important to determine whether they can help select polymers. There are different types of synthetic plastics, including:

Standard polymer

Engineering polymer

High performance polymer

Each polymer type has different advantages, and each has its unique advantages, disadvantages and applications. Therefore, the supplier needs to be able to inform and advise what is the most suitable material for the job requirements.

Design capability and internal tool manufacturing

When selecting injection molding suppliers, it may be beneficial to select suppliers with design capability and internal tool manufacturing facilities. This means that the injection molding process, including the design stage and tool manufacturing, is completed under one roof. This enables the team to communicate in a timely manner at each step, eliminates possible supply chain delays and encourages efficient project workflow.

Certified quality management system

The quality management system (QMS) is designed to help organizations meet the needs of customers and key stakeholders. Whether it's tool manufacturing or injection molding. The recognized international QMS system is ISO 9001, which is based on seven quality management principles, including customer focus, the participation of senior management and the motivation for continuous improvement.

Post molding service

Once your parts are manufactured, the service will not stop. Ultrasonic welding is a common technology in plastic injection molding industry. Two parts are connected together by high-frequency ultrasonic vibration. The finished product is composed of glue free joints without connecting bolts, screws or fasteners.

One of the most significant benefits of ultrasonic welding is that it is a cost-effective way to connect parts, which can help designers overcome the design limitations sometimes encountered by other connection methods. Our ultrasonic welding equipment can weld all kinds of thermoplastic parts. The equipment is highly reliable and repeatable, and can be used for other functions, including riveting, swaging and insertion.

Pad printing is a process that can add details to your product to improve usability and personal style, and it is a valuable way to emphasize some parts of the product. For example, you can transfer the safety function to the device to explain the correct operation to the user, or print the serial number or traceability information to the product when necessary.

We have two color pad printing machines in-house, and have a perfect supply chain of coating, RFI coating and other special post-treatment operations. The flexibility of pad printing enables us to print high-resolution and clear designs on almost any product, regardless of size or shape. The variety of inks available means that we can match colors to suit your company's corporate color and brand guide.

Benefits of project management

Project management aims to improve customer satisfaction through efficient, transparent and successful project planning. The designated project manager is responsible for helping to deliver the expected results of the project while avoiding any unexpected costs. Successful project managers provide updates and information to internal and external personnel, bring transparency and act as intermediaries between customers and manufacturers.

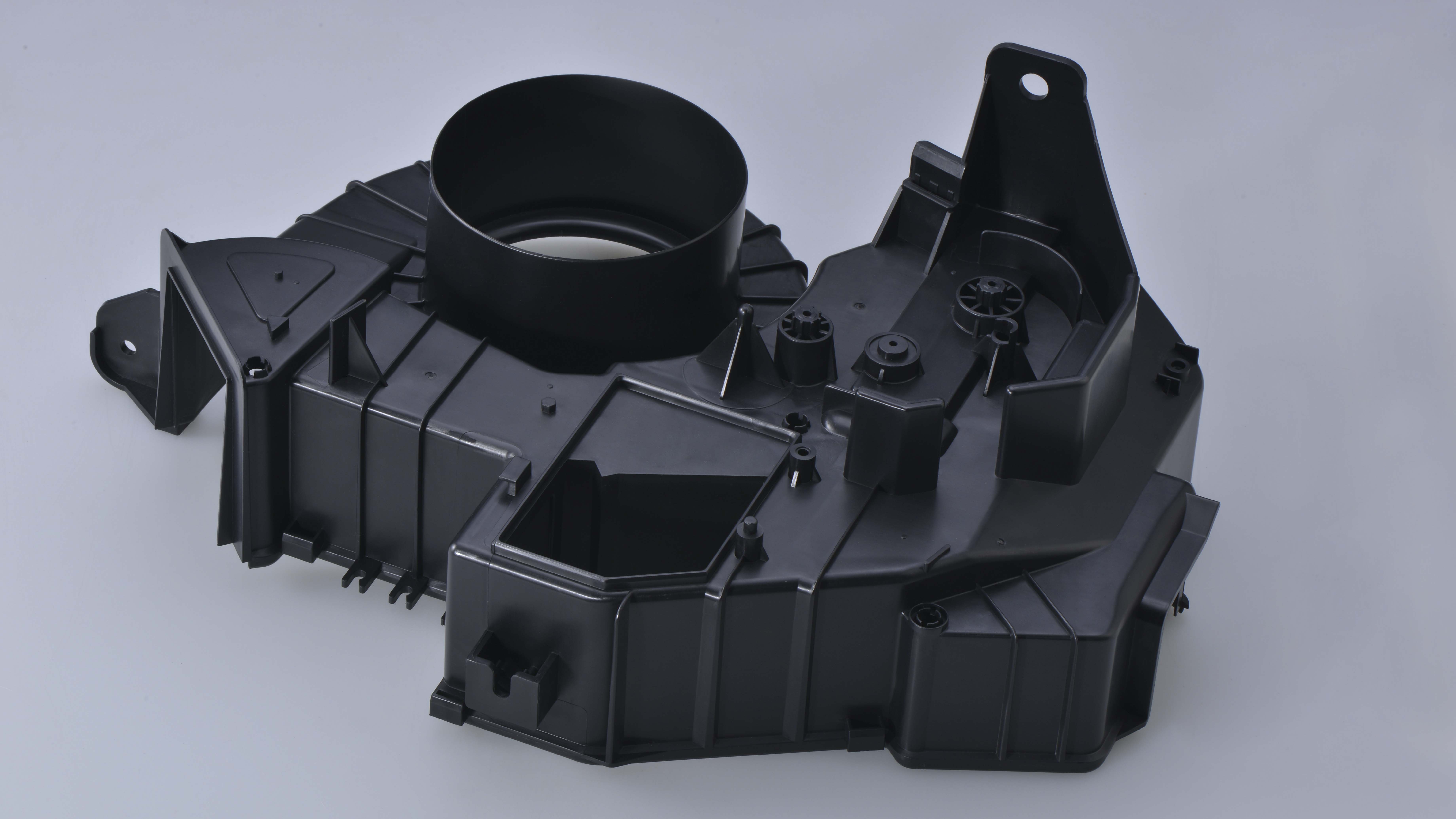

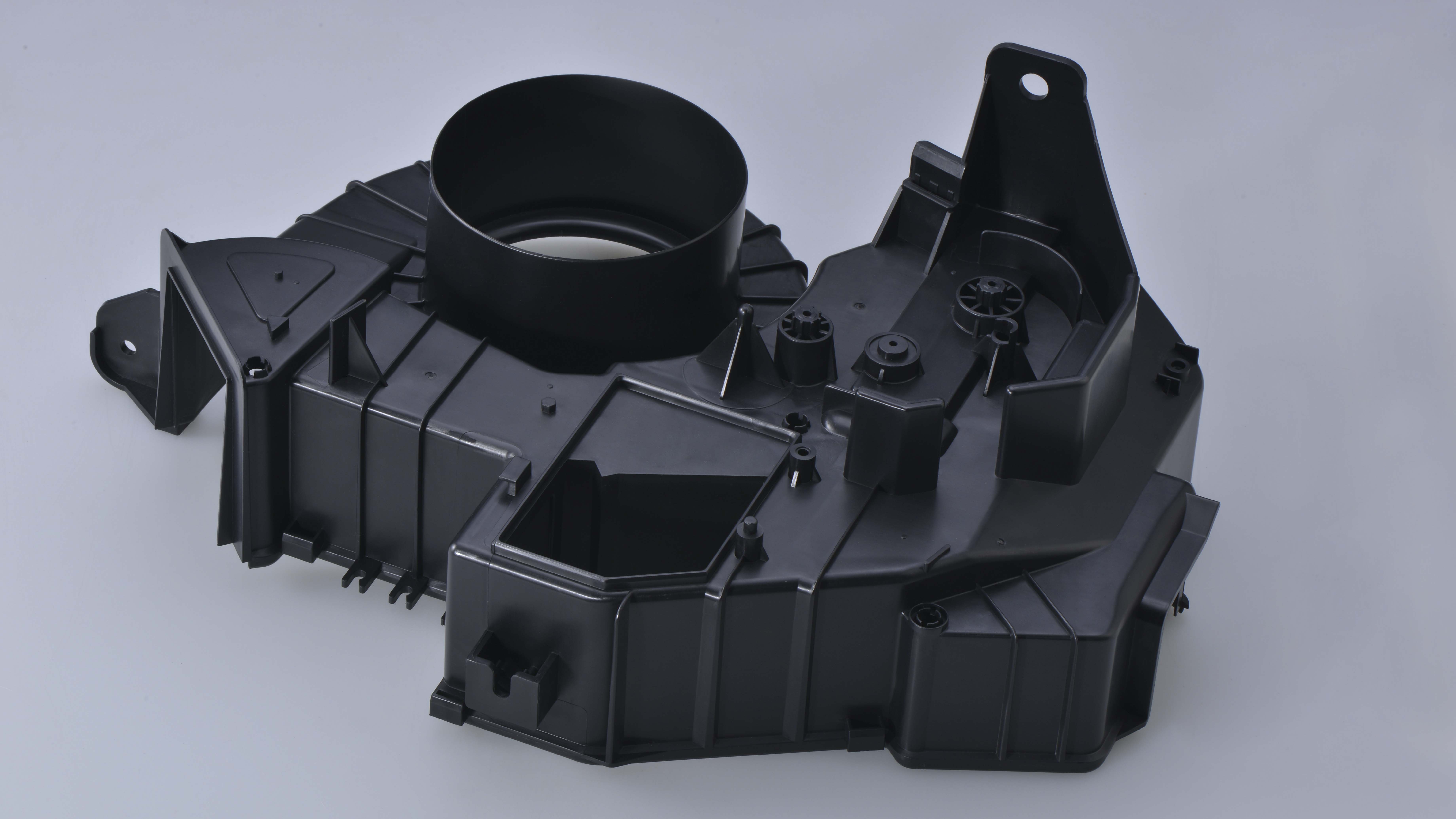

A range of mechanical dimensions increase flexibility

Injection molding machine is called "fixture tonnage". Tonnage determines the force required to keep the injection mold closed during the molding process, which is the main factor determining the size of the molding machine required to produce parts. Larger products or molds with multiple cavities (multiple components per machine cycle) will require larger tonnage machines because more force is required in the whole process.

Considering that suppliers of machines with the correct size are important for the efficiency and flexibility of molding projects. In

Mastars, our machines range from 20t to 650T, enabling us to adapt to all projects from small to large parts.

To learn how to support you in the injection molding process, please contact us immediately and we will be happy to meet your needs.

Mastars Industries CO., LTD

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210690

Mobile: +86 181 0029 4997

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China