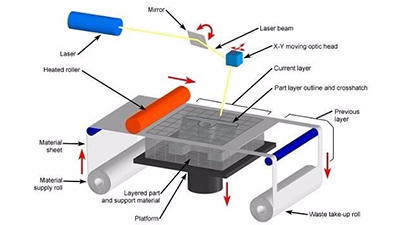

3D printing company chooses mastars' one-stop manufacturing service, which is deeply trusted by many enterprises. It provides rapid proofing and mass production services including CNC machining, sheet metal processing, and other processes

Decades ago, people may not have thought that with the emergence of CNC machine tools, this technology will replace the traditional manual operation. However, when new technologies appear, there will always be some voices of doubt. At the same time, there are also some people who can seize the opportunity to stand out. Will 3D printing be the next one?

Evolve additional solutions said that whenever possible, the design advantages of

3D printing will play a role. At present, the company has begun to use 3D printing technology to produce polymer components at high speed.

For traditional processes, 3D printing has the advantages of cost saving, faster manufacturing speed, reducing inventory pressure, solving supply chain problems, and improving design performance

So far, the progress of 3D printing has been to prove its commercial value by meeting the needs that cannot be met by other production processes. Many of them are related to parts consolidation, lightweight, complex forms, customization and small batch production. In most cases, this technology can prove the advantage of improving performance by changing the original design. Even if the unit cost is increased, customers feel it is reasonable.

But can there be a more balanced possibility in the future, that is, to achieve high-speed mass production and lower cost?

Therefore, some people have been innovating in new methods that are more competitive with the traditional process. For example, evolve has developed a new 3D printing technology step (choose thermoplastic electrophotographic process), which can produce polymer parts at a higher speed and at a price closer to the traditional process.