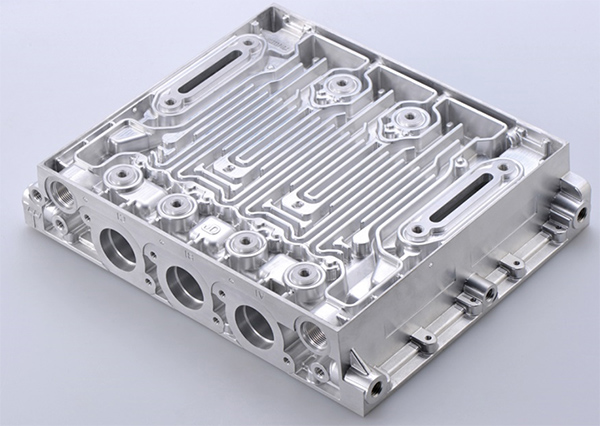

Mastars uses Rapid CNC Machining not only to manufacture parts and prototypes but also to make mold tools, which can be used for our Rapid Injection Molding or Rapid Pressure Die Casting services. Mastars provides global customers with high-performance, high reliability and high flexibility Rapid CNC Machining services.

Our metal CNC machining facility produces both large and small parts for many industries including automotive, aerospace, marine, construction, scientific, oil, gas and medical.

5 axis capability, the latest CAD/CAM software and experience of machining most metals, enable us to produce highly accurate parts in low and high volume batches.

We can also offer finishing services including polishing, chrome plating, gold plating, spray painting powder coating, hot dipping and anodizing.

Rapid CNC Machining is a fast and cost-effective way to make a few precision prototype with plastic and metal material. It was widely used in new product development and design. Of course, it is also a common method to make volume manufacturing for some parts in limit of molding.

CNC means that cutting your materials by using the computer arithmetical control system. When it comes to our Rapid CNC machining, it is a unique and efficient machine aimed to interpret 3D CAD form before translating essential information to the systems. The most beneficial reason to use this service is that it will create the parts that will easily replace addictive manufactured or invention prototypes by using real production grade resources. It aids you in building the parts in a featured material which you actually intend for utilizing in development. Rapid CNC Machining is a perfect option for speedy prototyping of superior quality metal or plastic parts that requires an increased range of dimensional accurateness, crucial surface finishes and material-specific features.

Affordable solutions

If you want to get the best possible results, it is advised to opt for Mastars. We are an expert team of professionals who are dedicated to offering the desired level of services to our industry clients. The specialized feature of our company is that we use an excellent technology to provide suitable solutions based on your individual requirements. Rapid CNC Machining appears as an affordable and quick way for making an accurate prototype by using suitable materials.

Where to use Rapid CNC machining?

We have the 5 axises capacity of our services. We let our customers enjoy precision, fast results, and huge size range. CNC refers to cutting material with a computer numerical control machine. CNC machining is a subtractive manufacturing process where raw material is removed with a variety of precision cutting tools to make a part or product. Advanced software is used to control the equipment according to the specification of your 3D design. Our team of engineers and machinists program the equipment to optimize cutting time, surface finish and final tolerance to meet your specifications. Mastars uses Rapid CNC Machining not only to manufacture parts and prototypes but also to make mold tools, which can be used for our Rapid Injection Molding or Rapid Pressure Die Casting services. The CNC machining process interprets your 3D CAD model and translates data to CNC machines. The main benefit of the process is that CNC will produce parts that can replace the additive manufactured prototypes with true production grade materials. CNC machining is the best choice for rapid prototyping of high-quality metal and plastic parts requiring the greatest degree of dimensional accuracy, critical surface finishes, material-specific properties. We work with a wide range of plastic and metal materials including magnesium, steel, aluminum, brass and titanium to make tooling for plastic injection molding and pressure die casting or to make parts for rapid prototypes and Low Volume Production.

Rapid Prototype Tooling Service

We make hard tooling (cores and cavities) from a variety of materials to suit your budget, order volume and schedule. Specialty metals can also be ordered on request. Learn more about our rapid prototype tooling service.

Benefits of Rapid CNC Machining

The benefits of Rapid CNC Machining are numerous. Once a tool path is created and a machine is programmed, it can run a part 1 time, or 100,000 times. CNC machines are built for precise manufacturing and repeatability which makes them cost-efficient and highly scalable. CNC machines can also work with a variety of materials from basic aluminum and plastics to more exotic materials like titanium — making them the ideal machine for almost any job. That's why Rapid CNC Machining is one of the most popular methods of making plastic and metal components.

Whether for rapid prototypes or production parts, Mastars has the right Rapid CNC Machining options for your metal and plastic part needs.

• Wide range of materials

• Ability to hold tight tolerances

• Parts machined directly from 3D CAD models

• Standard delivery time of 1-2 weeks based on order

• Shorter lead time (2-5 business days) available per open capacity

CNC Machining is crucial in many industries such as aerospace and defense, automotive, energy, industrial machinery, medical, robotics, and R&D. These machines are also vital to other manufacturing processes. For example, the molds required for Rapid Injection Molding are CNC machined to ensure the precision of both the mold and the plastic part it makes. Rapid CNC Machining is one of the fastest ways to build functional prototypes, product molds, low to high volume production runs, and fixtures.

For more information on our rapid prototype machining services, contact us today. Or Request a Quote to receive competitive pricing. Please mention the expected delivery time. This will help us serve you the best.

Mastars are principally engaged in the manufacture of plastic/metal parts business including automotive, industrial and moulds. As manufacturing expertise in China, we provide philosophy, customers benefit from our unique blend of philosophy, customers benefit from our unique blend of quality, reasonable cost, integrated services and flexibiliy.