Metal surface chrome plating process

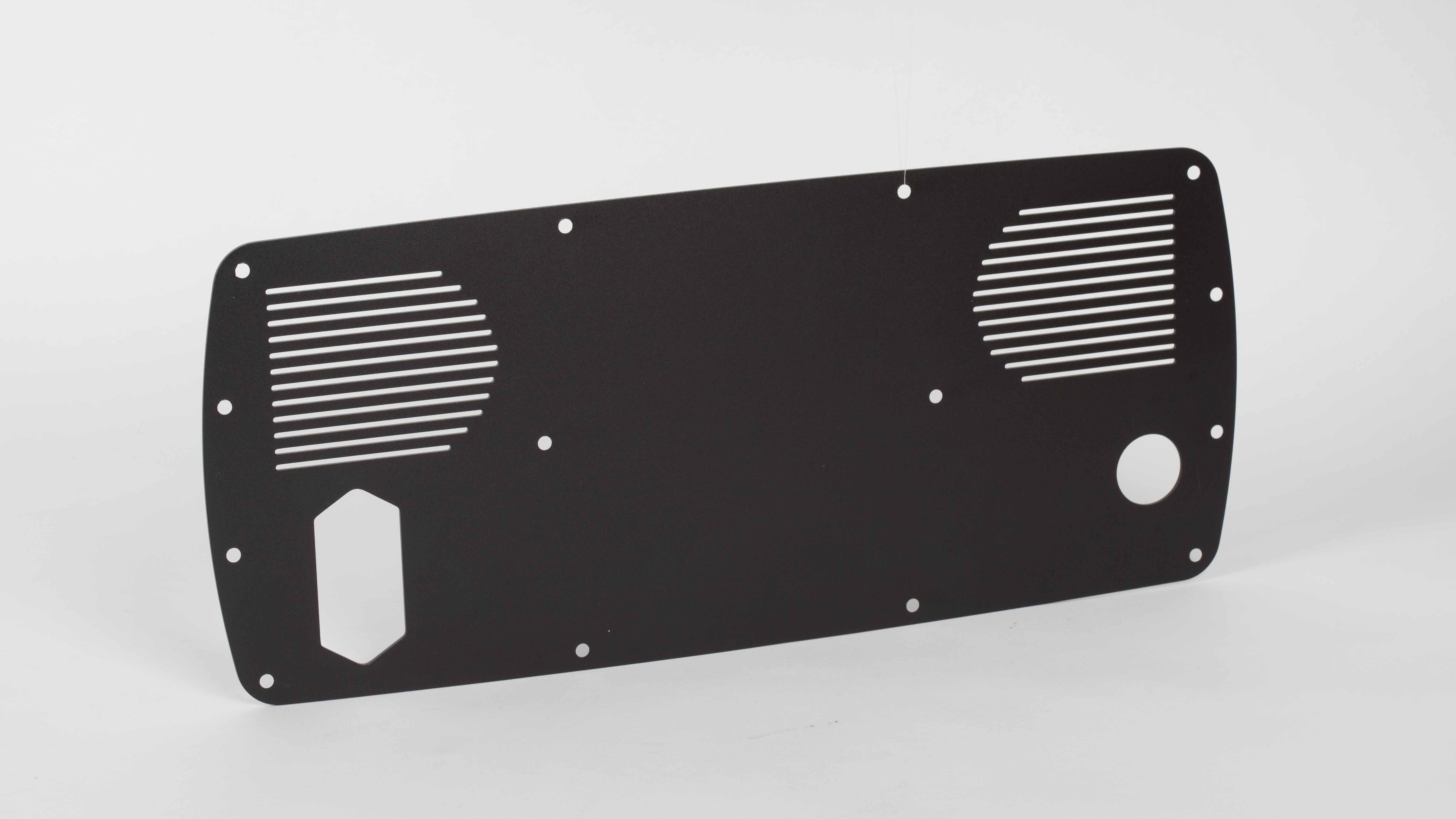

Mastars is a metal prototype manufacturer and also produces mass-produced products. In the production process of metal products, after using CNC processing and other processes, the product surface needs to be further treated, including chrome plating.

Chrome plating surface treatment process

Chrome plating is a common method of metal surface treatment, and metal chromium is easily passivated in the air to form a dense oxide film. The surface of the parts after processing is smooth and bright, rust-resistant and wear-resistant, and the hardness is very high. It is generally used in occasions with high requirements on roughness, wear resistance and corrosion resistance.

In mechanical design, generally speaking, chrome plating is called hard chrome plating. The thickness is usually more than 20um, and it is usually plated on the surface of metal parts, which can significantly improve the hardness, wear resistance, smoothness, corrosion resistance and high temperature resistance of the workpiece.

In addition, due to the good physical and chemical properties of hard chrome plating, hard chrome plating is often used to repair parts that have been excessively worn or cut, so that they can be reused.

The effect of direct chrome plating on the surface of metal parts is not ideal and easy to fall off. Multi-layer plating (copper-nickel-chromium plating) is recommended. Before electroplating, the surface roughness of the part needs to reach 3.2, because the roughness of the blank directly affects the roughness of the chrome-plated layer. The general processing process of blanks is as follows: machining - degreasing - washing - derusting - washing. The hardness of the chrome-plated layer can reach 800-1000HV, and it does not change color below 480℃, starts to oxidize at 500℃, and decreases in hardness at 700℃. The disadvantage is that it is brittle and easy to fall off, especially under the action of alternating impact load.

The nickel-plated surface is golden yellow with yellowish whiteness. The tin plating is silver-white, and the gloss is soft and not dazzling. Galvanizing is the most common, and there are many colors, including blue and white, colored zinc, and the surface is grainy and rough. Chrome plating is very shiny silver-white, with a delicate surface, and many cars also use chrome decorative strips.

Mastars:

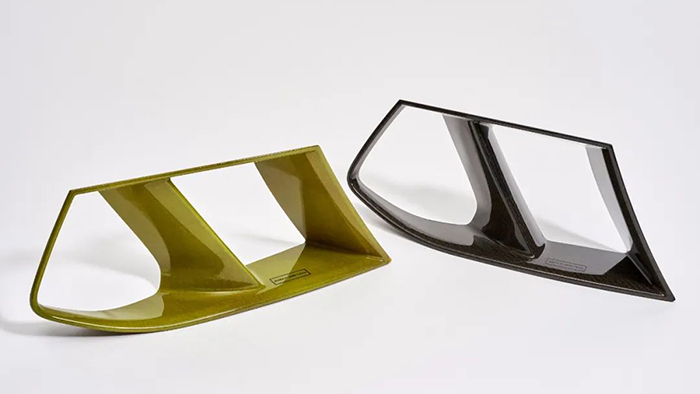

We employ proven prototype technologies(CNC machining, Vacuum casting, 3D printing etc.), to take new concept or design and bring it to life, develop and evaluate new products quickly, economically and with less risk. With lesson learn from prototyping, we provide considered and proactive tooling design/build and mass production processing, from injection molding, die casting, CNC machining to final assembly as full one-stop solution.

Our purpose is to make great products for our customers that create value and improve people's lives. We help a diverse customers base design, build and deliver the products that make the world a better place.

Our vision is to be the most reliable and valuable manufacturer supplier in the world.

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210689

Fax: +86 755-8821 0685

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China

Contents