Additive manufacturing as an emerging technology has been widely used in prototype manufacturing. With the development of technology and material progress, additive manufacturing is increasingly used in batch direct production. So what is the digital production of additive manufacturing? |3D Printing|surface finishes for plastic

Is it a 3D printer factory with more than N sets in a row, or a large-scale interconnection of design management software? If we compare additive digital chemical plants with traditional injection molding plants, what are their respective advantages?

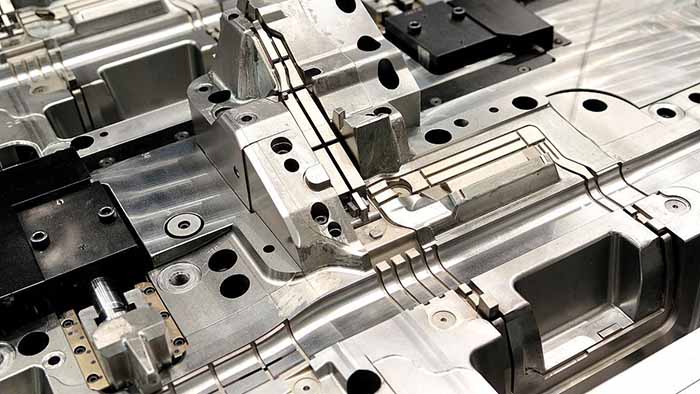

The choice of technology, materials, cost and management determines the core competitiveness of injection molding enterprises.

Injection molding is a method of injecting heated and melted materials into the mold, cooling and curing, and then forming plastic products. It is suitable for mass production of products with complex shapes.

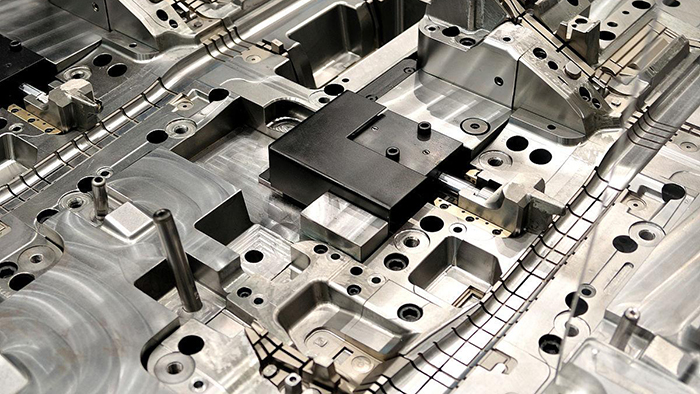

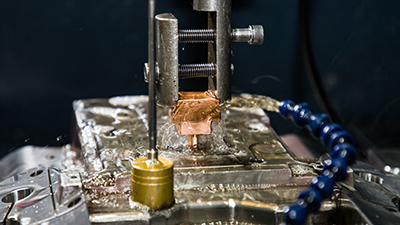

The design process of injection mold is very rigorous and time-consuming, ranging from product evaluation, mold flow analysis, ranking to design modification, ranging from a week to more than a month. The mold processing process has gone through many processes, such as rough machining, finish machining and polishing, which takes a long time and the start-up cost rises.

The injection molding process includes opening and closing the safety door, mold locking, injection pressure maintaining, cooling, mold opening, taking out and other main steps, and the operation process is repeated for continuous production. This process is the comprehensive management of materials, equipment, molds and parameter settings, which requires rich experience and supporting post-treatment process.

● performance problems: warpage, stress, uneven density, etc.

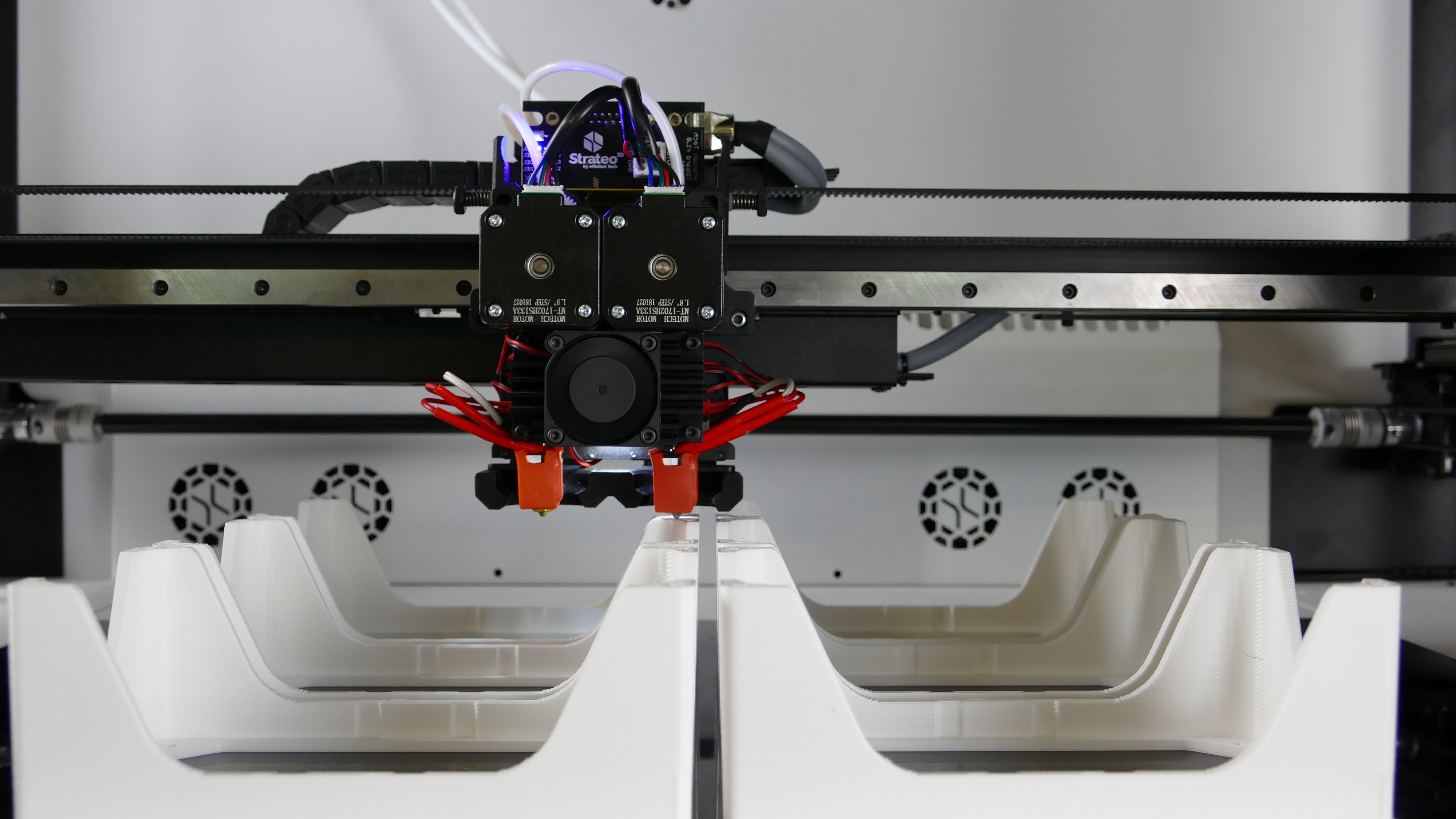

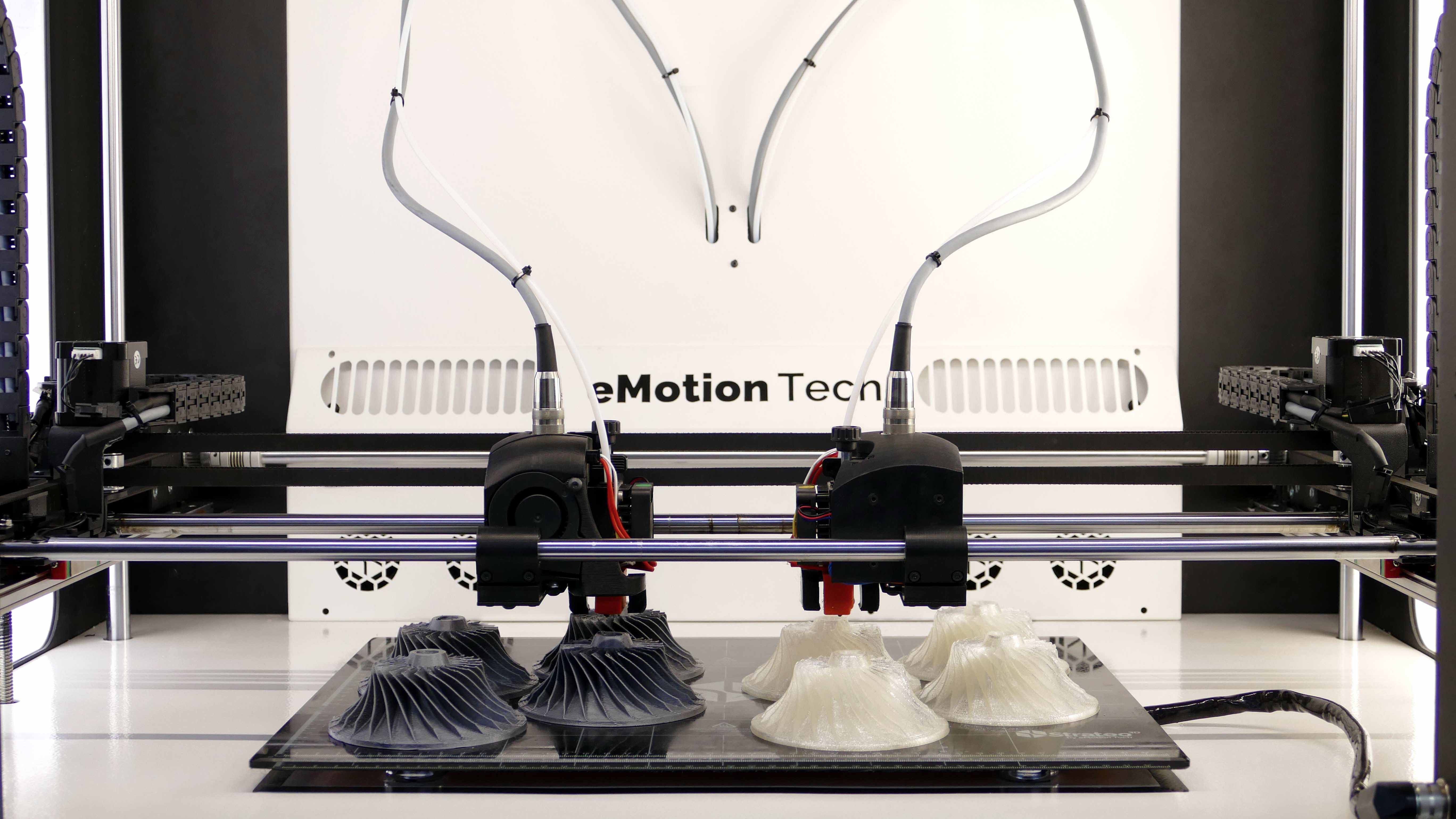

Cad/cam software is directly used to design the final finished parts instead of molds. 3D printing can meet the functional or structural requirements during design, such as organic or complex internal cavities, reduced number of parts, and the use of higher strength additives to manufacture lightweight materials, which is applicable to almost all structures.

3D printing has become a common method of producing prototypes and short-term production parts, because it saves the manufacturing time and cost of molds. It can work continuously after reading cad/cam data. There is no need for special personnel to be on duty, and there is no risk of mold damage. Several plastic products rise from the forming platform at a speed of mm per minute.

The software design aims to realize the local operation and intelligent support of the factory, and carry out remote operation through network and cloud connection, so as to promote the efficient data exchange of intelligent manufacturing. Digital, analog manufacturing and testing of plastic or metal parts will liberate the production process from the demand for mold processing, and provide a manufacturing mode with flexibility and capacity for enterprise production.

Additive manufacturing digital chemical plant is more suitable for the production of small batch orders or the customization of complex structural parts. It has its application range and needs to be quantitatively evaluated based on the characteristics of each enterprise. In addition, the new digital production mode requires enterprises to adopt matching end-to-end management skills.

When hundreds of thousands of output is needed, mold + injection molding is still the priority. On the other hand, when the number of orders is less than 2000 for small batch manufacturing, additive manufacturing digital chemical plant will have a significant advantage. In this case, the cost of each injection molded part may be 10 to 100 times that of additive manufacturing digital production.

In addition to the actual production costs of traditional injection molded parts, there are other financial factors to consider, such as labor costs and supply chain management: additional labor, materials and CNC processing, testing costs, etc. 3D printing digital production reduces the marginal cost. If the appearance and function of the product are not as expected, it can be modified in CAD at any time and manufactured immediately - there is no need to design new molds.

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210690

+86 18100294997

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China