Prototyping: Professional Terminology

Category 1: Core Concepts & Philosophies

|

Term |

Definition & Context |

|

Prototype |

A preliminary model of a product, built to

test a concept, validate functionality, or communicate ideas. |

|

Prototyping |

The process of creating a prototype. A core

activity in design thinking and agile development. |

|

Proof of Concept (PoC) |

A prototype built solely to verify that a

certain concept or theory has the potential to be used. Focuses on core

functionality, not form. |

|

Minimum Viable Product (MVP) |

A prototype with just enough features to

satisfy early customers and provide feedback for future product development.

It tests the product's value in the market. |

|

Iterative Design |

A cyclical design methodology based on

prototyping, testing, analyzing, and refining a product. |

|

Fail Fast, Fail Cheap |

A key philosophy of prototyping. The goal

is to discover flaws and shortcomings as early and inexpensively as possible. |

|

Design Validation |

Using a prototype to confirm that the

product meets the intended design specifications and user needs. |

|

User Testing |

The process of having end-users interact

with a prototype to identify usability issues and gather feedback. |

Category 2: Fidelity & Purpose

These terms describe the detail level and

primary goal of a prototype.

|

Term |

Definition & Context |

|

Fidelity |

The level of detail and functionality of a

prototype. Ranges from Low-Fidelity to High-Fidelity. |

|

Low-Fidelity (Lo-Fi) Prototype |

A simple, abstract, and quick-to-make

prototype. Used to explore concepts, test flow, and layout without

distraction. Examples: Sketches, wireframes, paper prototypes. |

|

High-Fidelity (Hi-Fi) Prototype |

A prototype that closely resembles the

final product in look, feel, and interaction. Used for detailed usability

testing and final design validation. |

|

Horizontal Prototype |

A broad but shallow prototype that shows a

wide range of features but with little detail (e.g., a mockup of an entire

website's top-level navigation). |

|

Vertical Prototype |

A narrow but deep prototype that implements

a single feature or workflow in full detail from start to finish. |

|

Looks-Like Prototype |

A prototype that accurately represents the

final product's visual design, form, and aesthetics, but may not be

functional. |

|

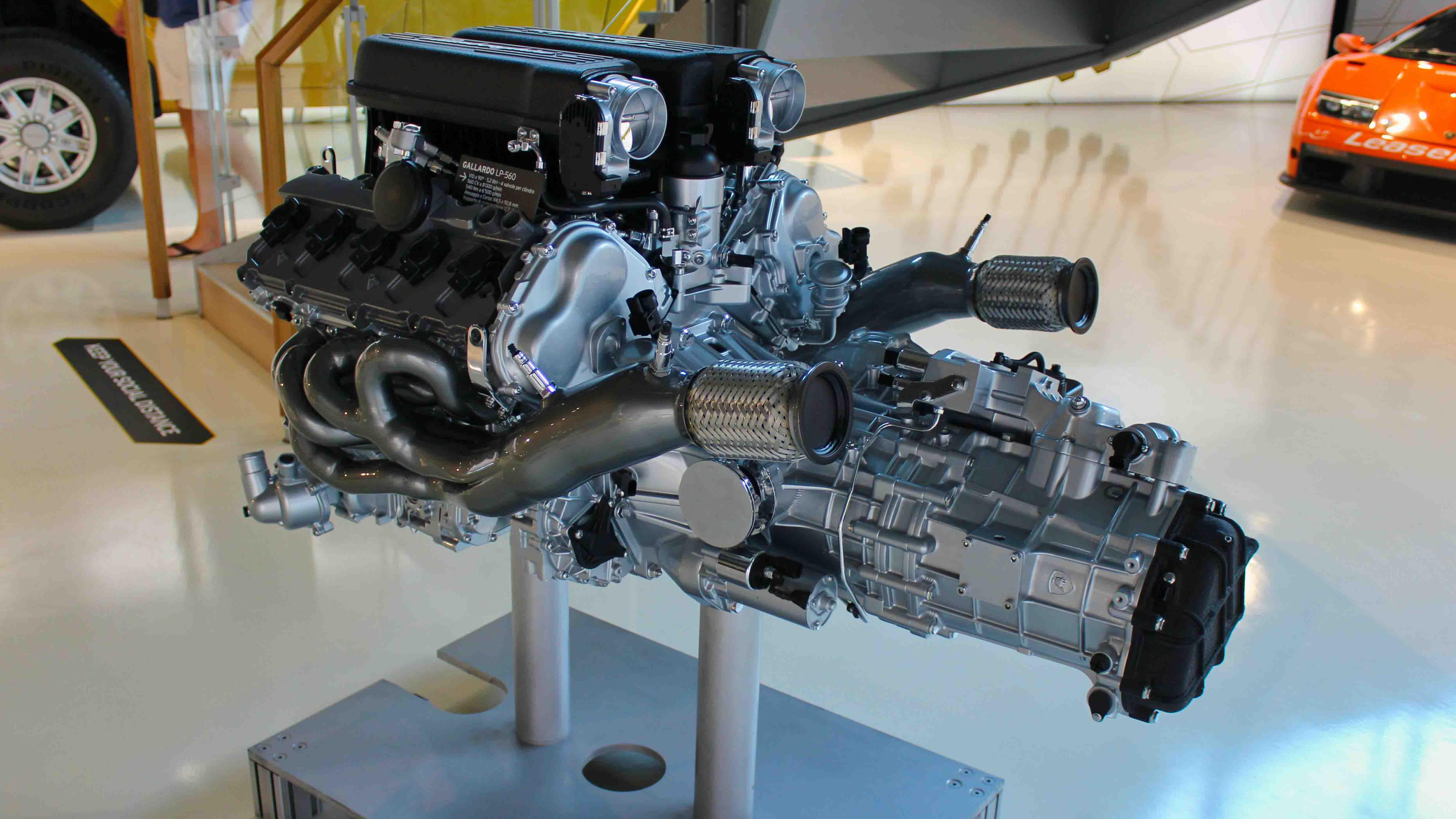

Works-Like Prototype |

A prototype that functions like the final

product (e.g., electronics, mechanics) but may not have the final exterior. |

|

Feels-Like Prototype |

A prototype focused on the user experience

(UX), interaction, and ergonomics. |

Category 3: Physical Prototyping Methods & Outputs

|

Term |

Definition & Context |

|

Appearance Model |

A high-fidelity, non-functional model

created to represent the final product's exact size, shape, color, and

texture. Used for marketing and approval. |

|

Engineering Prototype |

A functional prototype built to test

technical performance, durability, and manufacturing feasibility. |

|

Scale Model |

A prototype that is a proportional

enlargement or reduction of the actual product. |

|

Mock-up |

A often full-scale model used for design,

evaluation, or promotion. It may be static or have limited functionality. |

|

Breadboard |

An early-stage electronics prototype,

typically on a perforated board, used to test circuit design without

soldering. |

|

Form Factor Model |

A prototype built specifically to test the

physical dimensions, layout, and ergonomics of a device. |

Category 4: Digital/Software Prototyping

|

Term |

Definition & Context |

|

Wireframe |

A low-fidelity, skeletal outline of a

digital interface (website/app), showing the layout of elements and

functionality. |

|

Mock-up |

A medium-fidelity static design of a

digital product. It incorporates visual design (colors, typography) but is

not interactive. |

|

Interactive Prototype |

A clickable simulation of a digital

product. It allows users to navigate between screens and experience the flow. |

|

Digital Twin |

A virtual model of a physical product or

process, used for simulation, analysis, and control. |

Category 5: Modern Manufacturing Methods for Prototyping

|

Term |

Definition & Context |

|

Additive Manufacturing (AM) |

The formal term for 3D printing. Building

parts layer-by-layer from digital models. |

|

3D Printing |

The common term for Additive Manufacturing.

Ideal for rapid iteration of complex geometries. |

|

Fused Deposition Modeling (FDM) |

A common 3D printing process that uses a

continuous filament of thermoplastic material. |

|

Stereolithography (SLA) |

A 3D printing process that uses a laser to

cure liquid resin into hardened plastic. Known for high detail and smooth

surface finish. |

|

Selective Laser Sintering (SLS) |

A 3D printing process that uses a laser to

sinter powdered material (typically nylon). Known for creating strong,

functional parts without support structures. |

|

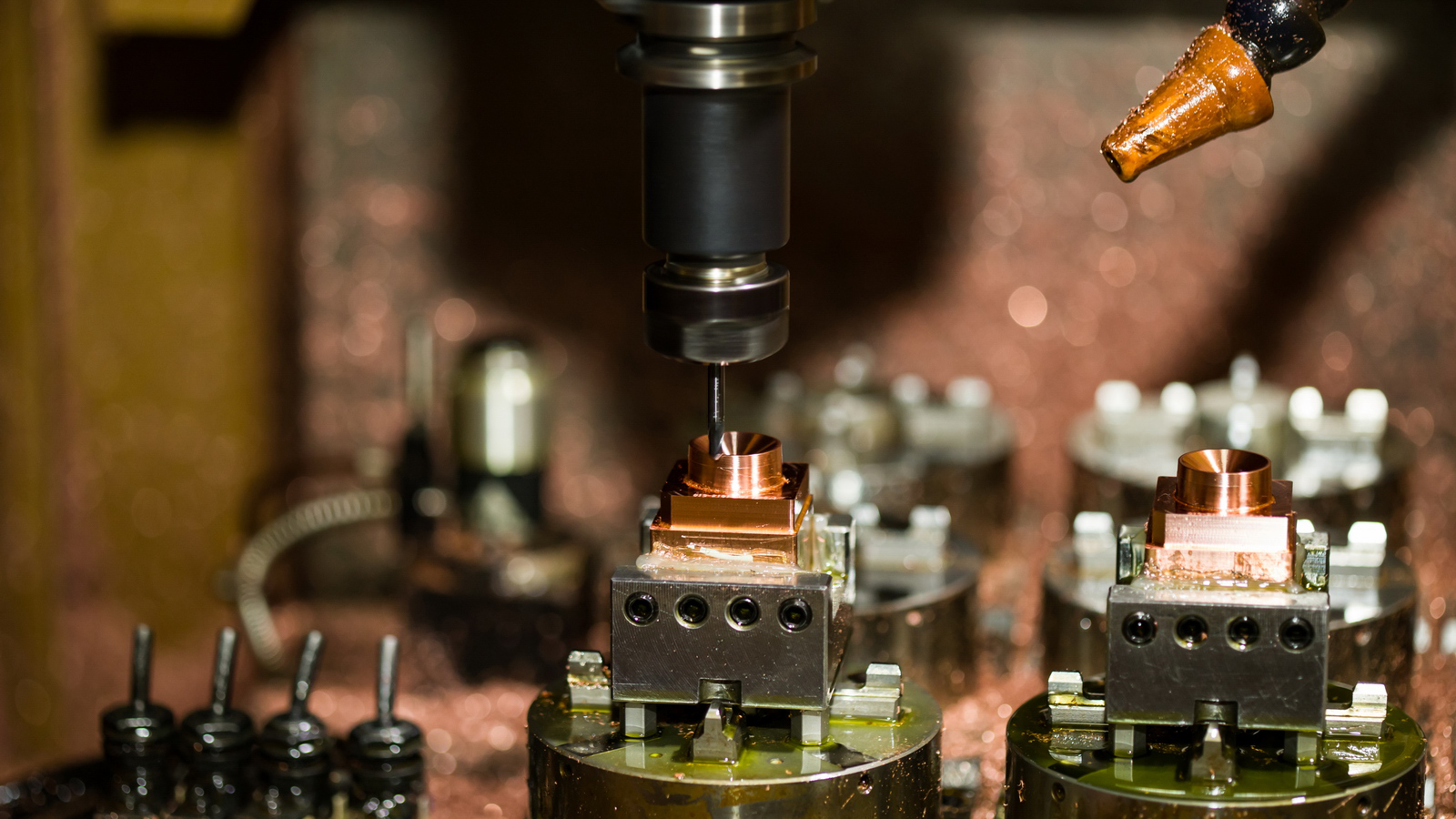

Subtractive Manufacturing |

The opposite of additive; starting with a

solid block of material and removing material (e.g., milling, cutting,

turning) to create a part. |

|

CNC Machining |

Computer Numerical Control machining. A

subtractive process ideal for creating high-strength, precise prototypes from

real engineering materials (metals, plastics). |

|

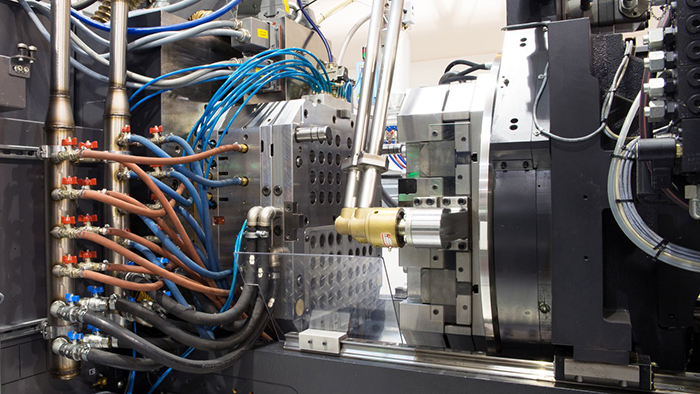

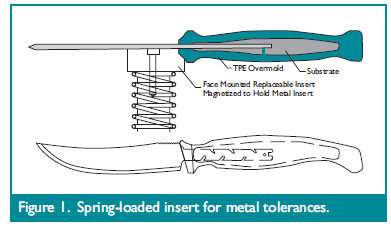

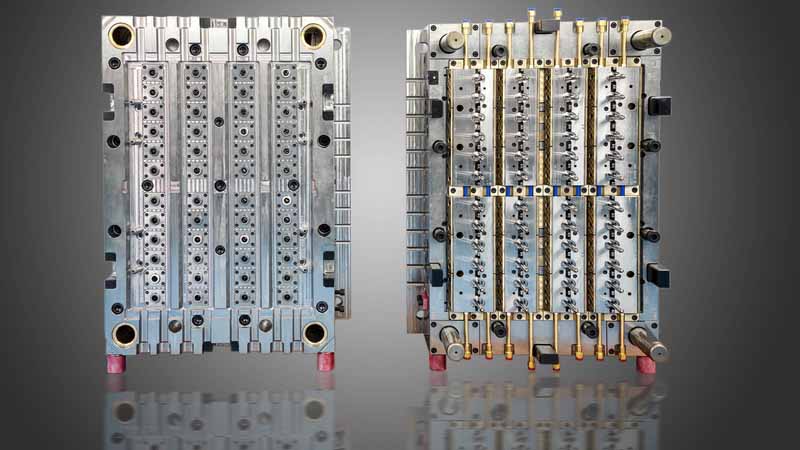

Rapid Tooling |

Methods to create molds quickly for

short-run production of prototypes in the final material (e.g., Urethane

Casting, 3D-printed

mold inserts). |

|

Vacuum Casting |

A process where a silicone mold is made

from a master pattern (often 3D printed) and used to cast multiple copies of

a part in polyurethane resin. |

Category 6: The Prototyping Workflow & Evaluation

|

Term |

Definition & Context |

|

Iteration |

A single cycle of the design process:

prototype -> test -> learn -> refine. |

|

Design for Manufacturability (DFM) |

The practice of designing parts to simplify

the manufacturing process, reducing cost and increasing quality. Prototyping

is key to DFM. |

|

Usability Testing |

Observing users as they interact with a

prototype to identify points of confusion and areas for improvement. |

|

Feedback Loop |

The process of gathering feedback on a

prototype and using it to inform the next iteration. |

|

A/B Testing |

Comparing two versions of a design (A and

B) with users to see which one performs better against a defined goal. |