Contents:

rapid prototyping services

CNC machining, Vacuum casting, 3D printing

injection molding, die casting

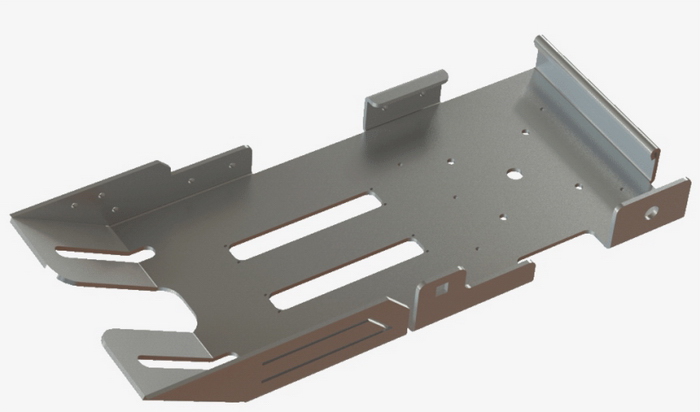

What are the procedures and rules of sheet metal design? Sheet metal process is one of the common processes used by Mastars for rapid prototyping services. The sheet metal design needs to go through a thorough checking process to avoid any design errors. As revealed by research reports, manufacturers spend more than forty percent on fixing errors. More importantly, twenty-four percent of those errors are the outcome of manufacturability problems.

In addition to the functional requirements, the design of sheet metal parts must also consider the process requirements, assembly requirements and cost requirements. Compared with castings and forgings, the products made of sheet metal parts have higher strength, lighter structural weight, simple processing, simple equipment, flat shape and less machining allowance, which can reduce weight, shorten production cycle and reduce cost.

Functional requirements

It mainly meets the structural requirements, strength requirements, shielding, ventilation and heat dissipation requirements of the system, grounding conductivity, etc.

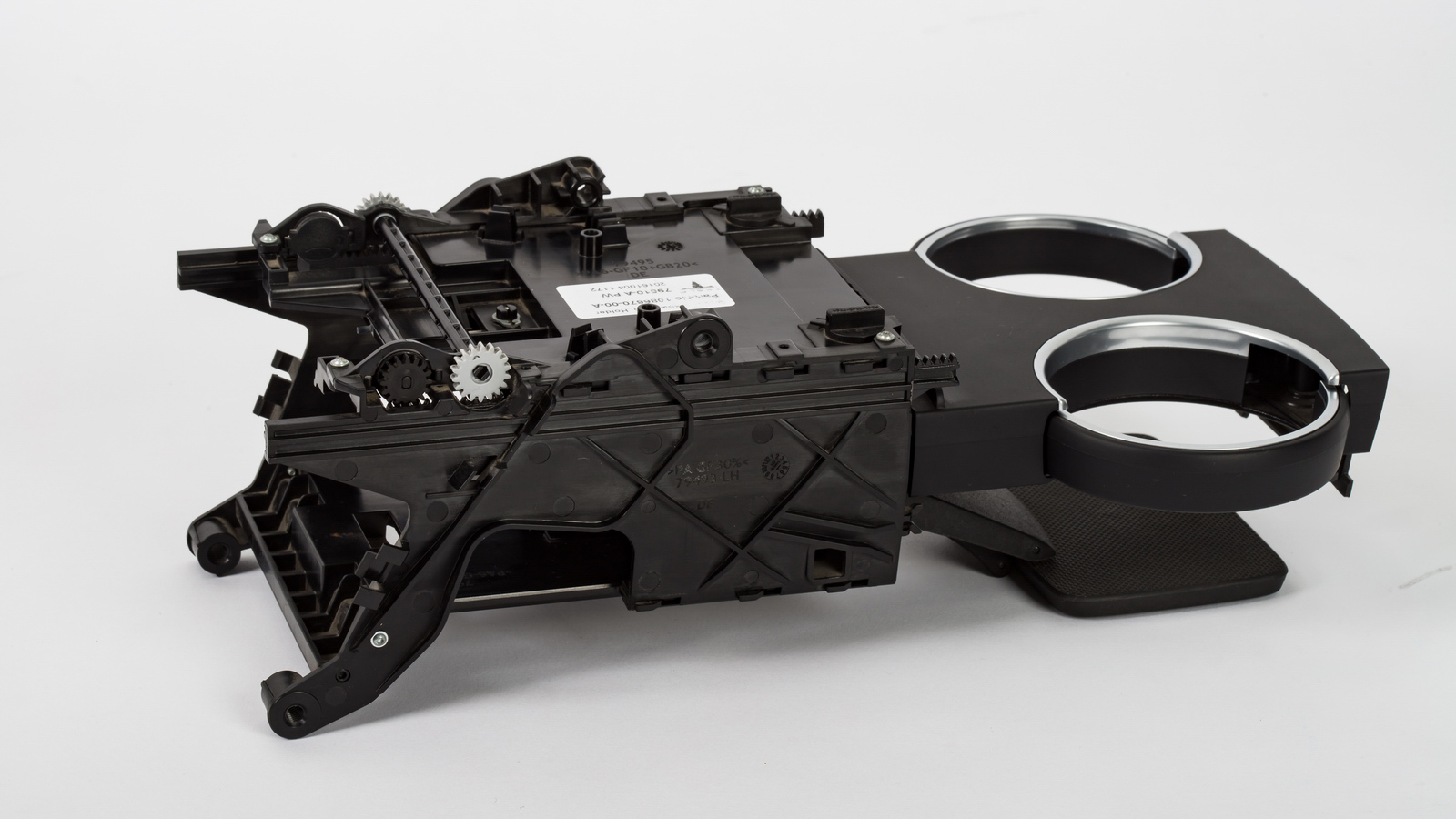

The structure of the system is the position, form, connection and assembly mode of the hardware, PCB board, wire, power supply, pipeline, instrument and equipment of the system. Because of its good strength, rigidity, processability and conductivity, sheet metal parts are usually used to support most of the hardware, PCB board, wire rod and power supply in the system. The placement forms of hardware are various, and its requirements will be different.

For example, where the PCB board is assembled, it can be considered to press riveting studs on the sheet metal parts for support, or punch a boss on the sheet metal parts for support, and then assemble with screws. For the fixation of wire rod, it can be considered to tie it on the sheet metal part with wire binding belt. Only the holes required by the specification of wire binding belt need to be punched on the sheet metal part. It can also be considered to punch the structure of wire binding on the sheet metal part.

strength requirements

Mechanical strength is the most important part in the design of sheet metal parts. Because most of the weight in the system is supported by sheet metal parts, if there is a problem with the mechanical strength of sheet metal parts, there will be a problem with the whole strength in the system.

Medical instruments generally need to do vibration test, drop test, collision test, impact test, etc. some machines even require strength to withstand 100g impact, which requires sufficient mechanical strength and rigidity. In particular, the sheet metal parts that need to support the empty hardware and the supports that play the main supporting role must have better strength.

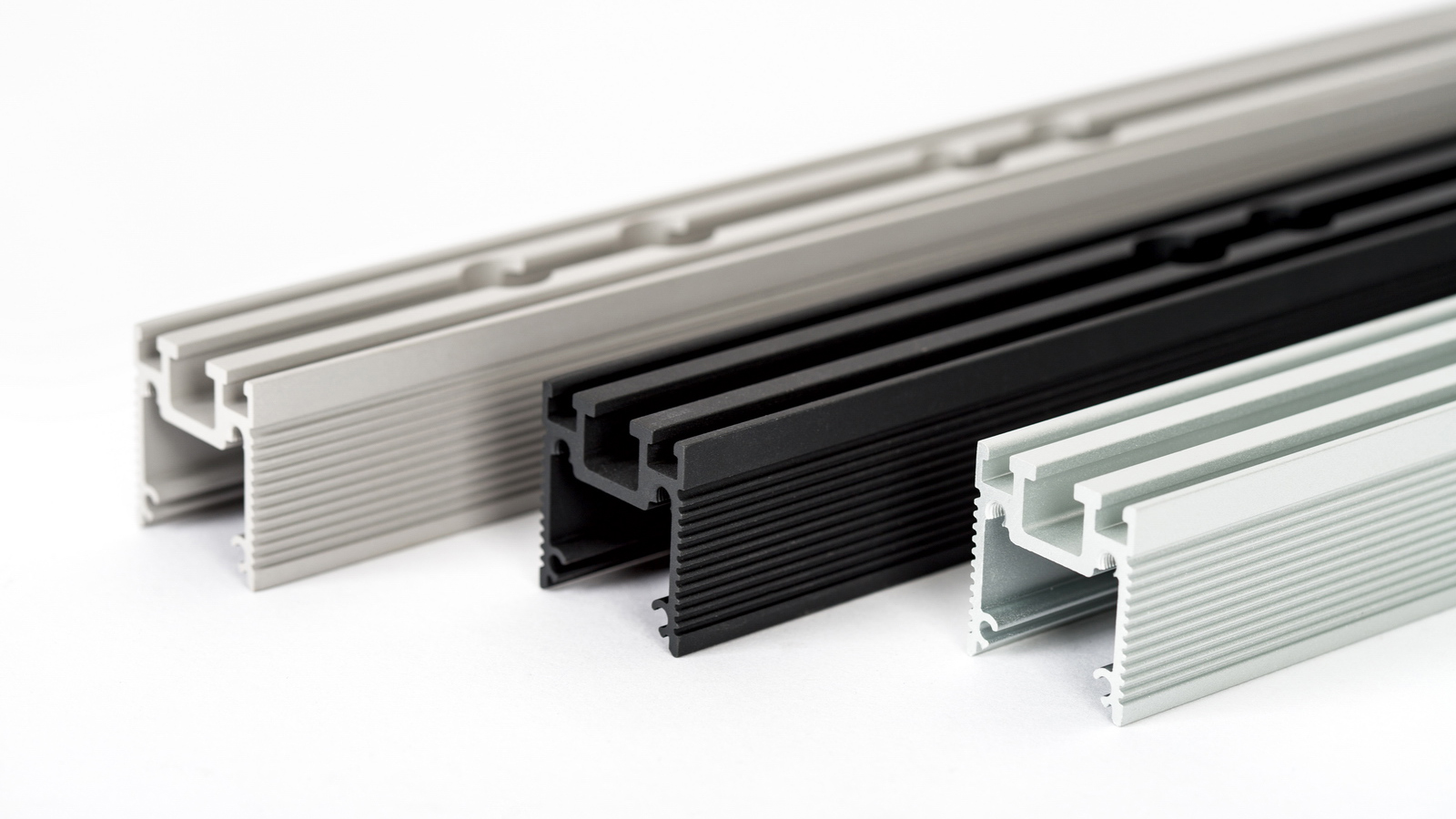

Generally, when designing large-scale systems, such as B-ultrasound, CT machine, inspection equipment, chassis and cabinets for communication, the support frame (rack) will be designed first. The bending degree of aluminum profile (such as steel profile) can be doubled.

Mastars:

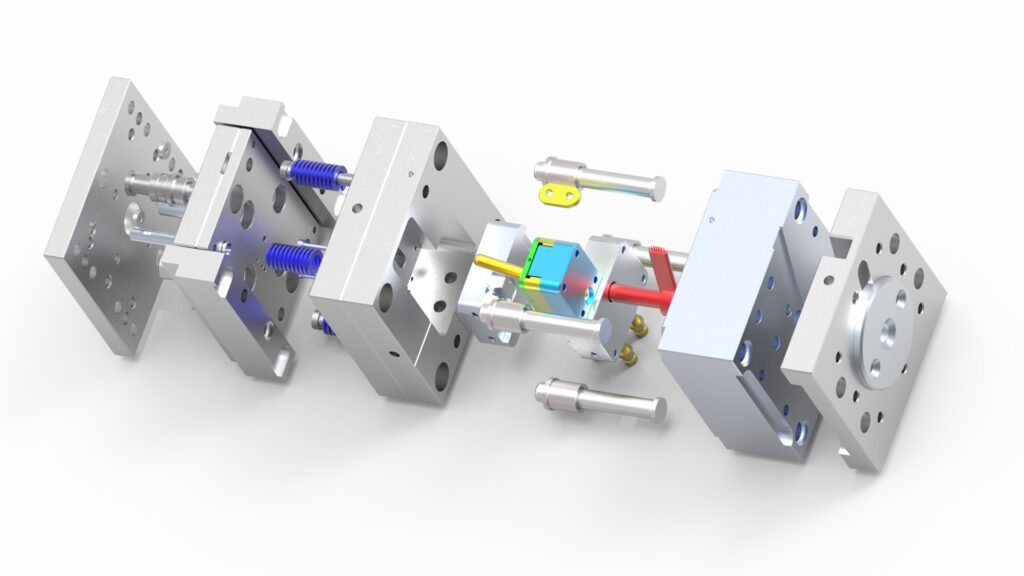

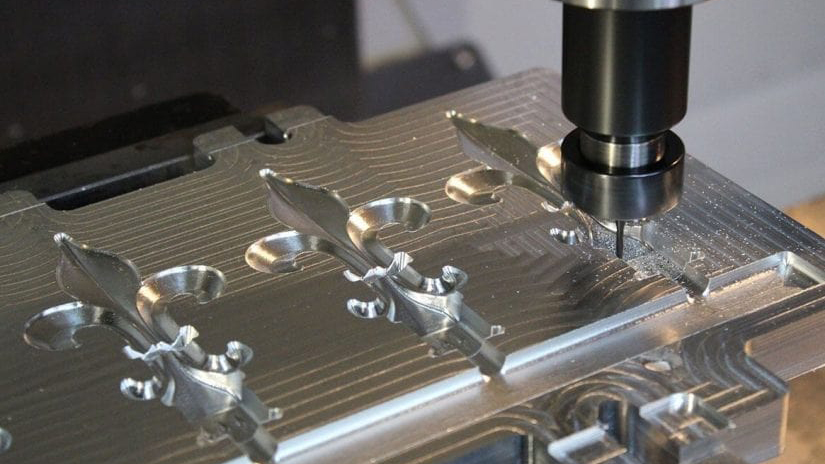

We employ proven prototype technologies(CNC machining, Vacuum casting, 3D printing etc.), to take new concept or design and bring it to life, develop and evaluate

new products quickly, economically and with less risk. With lesson learn from prototyping,

we provide considered and proactive tooling design/build and mass production processing,

from injection molding, die casting, CNC machining to final assembly as full

one-stop solution.

Our purpose is to make great products for our customers that create value and improve

people's lives. We help a diverse customers base design, build and deliver the products

that make the world a better place.

Our vision is to be the most reliable and valuable manufacturer supplier in the

world.