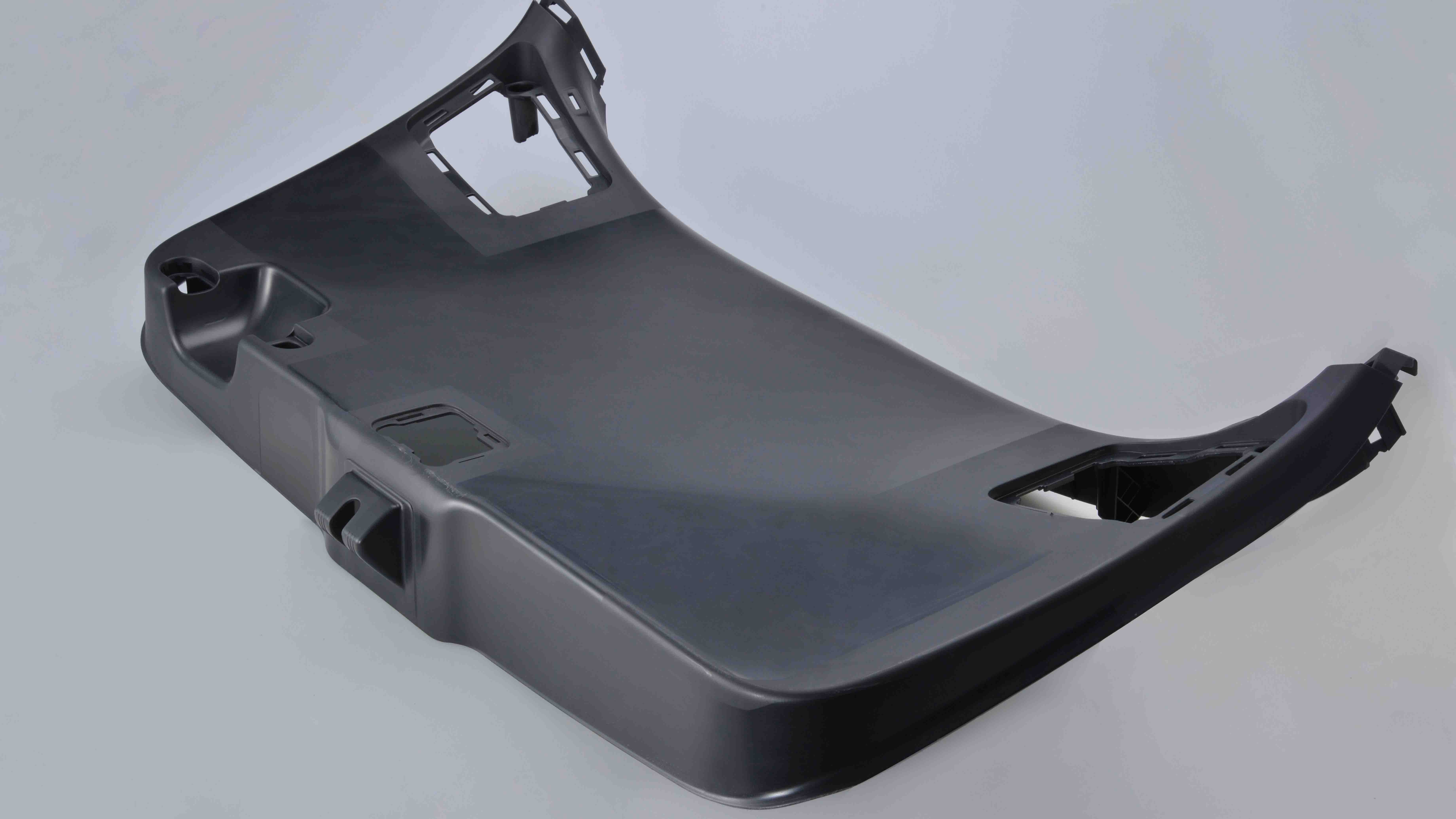

Gas assisted injection molding (grim) is a new injection molding process. In recent years, it has been widely used abroad and more and more in China. The principle is to use the inert gas with relatively low pressure to replace part of the resin in the medium-sized cavity in the traditional molding process to maintain the pressure, so as to achieve the purpose of better molding performance of products.

(1) Eliminate pores and depressions. Reasonably open air passages in the stiffeners and bosses set at the joints of different wall thicknesses of the workpiece. After the injection of insufficient material, the gas is introduced, which compensates the shrinkage of the melt during the cooling process and avoids the occurrence of pores and depressions.

(2) Reduce internal stress and warping deformation in the cooling process of the workpiece, a continuous gas channel is formed from the gas nozzle to the end of the material flow, without pressure loss, and the air pressure is consistent everywhere, so the residual stress is reduced and the warping deformation of the workpiece is prevented.

(3) Increase the strength of the parts. The design of hollow stiffeners and bosses on the parts makes the strength weight ratio about 5 higher than that of similar solid parts, and the moment of inertia of the parts is greatly improved, so as to improve the service strength of the parts.

(4) Improve the flexibility of design. Gas assisted injection can be used to form products with uneven wall thickness, so that the products that must be divided into several parts to be formed separately can be formed at one time, which is convenient for the assembly of parts. For example, a foreign company originally produced a car door panel with dozens of metal parts as the main body and complex shape, which was formed at one time through GAIM technology and plastic alloy materials.

(1) Save raw materials, and gas assisted injection molding can form a cavity in the thicker part of the product, which can reduce the weight of the finished product by 10% - 50%

(2) To reduce equipment costs, gas assisted injection requires less injection pressure and mold locking force than ordinary injection molding (25% - 50% can be saved), and 30% energy can be saved at the same time