Back in 2019, Dutch startup Lightyear showed off a

solar-powered electric car whose own solar panels automatically charge the car whenever it is exposed to the sun.|

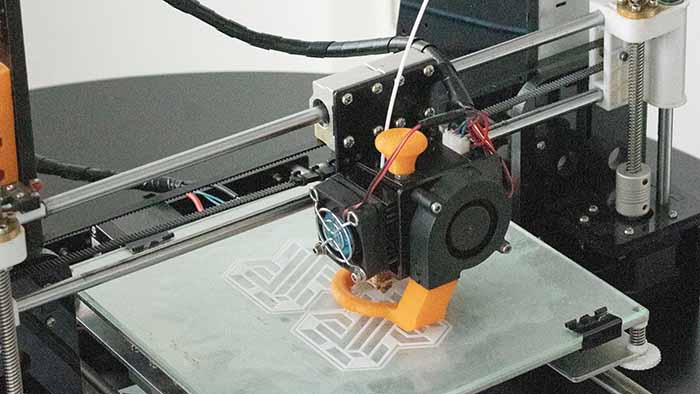

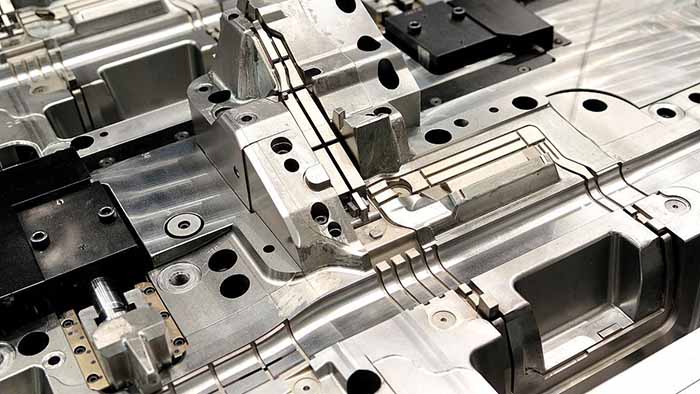

rapid prototyping services

Recently, after several years of improvement and testing, their production version was officially released under the name Lightyear 0.

The general design remains the same as the original prototype idea. Its biggest highlight is the charging, both equipped with a traditional electric car battery pack, but also installed a solar panel, can rely on the sun to "recharge"!

At the car's launch, Lightyear CEO and co-founder Lex Hoefsloot said, "Electric cars are a step in the right direction, but they are dependent on the grid, which still relies heavily on fossil fuel energy. Adding a new source of energy, solar power, adds certainty to the vehicle and you can always use solar power, thus reducing the number of recharges."

Externally, the body measures 5,083 mm long, 1,972 mm wide and 1,445 mm high, with a long, narrow, smooth body and a roofline that slopes slightly downward all the way to the rear of the vehicle.

The car is made of lightweight materials such as aluminum and carbon fiber, weighing 1575 kg. It is lighter and consumes less energy while maintaining a strong body. At the same time, the streamlined shape effectively reduces air resistance, with a drag coefficient of 0.19, and is equipped with specially developed Bridgestone tires, thus also reducing rolling resistance.

The interior of the Lightyear 0 is simple and is clad in a large amount of vegetable leather and renewable fabric made from recycled PET bottles. At the same time, the new car is also equipped with a full LCD instrument panel and a large floating center screen, with the outside camera connected to the sides of the display technology.

In terms of power, the Lightyear 0 is equipped with a conventional 60kWh EV battery pack and solar panels on the roof, hood and other parts of the car. As long as the car is exposed to sunlight, the solar panel will automatically charge, regardless of whether it is in driving condition. With four independent wheel motors providing power, plus a wind resistance coefficient of only 0.19 for the whole car, its energy consumption level can be 10.5kWh/100km.

Lightyear claims that solar power can provide the Lightyear 0 with a range of about 6,000 to 11,000 km per year.