CNC machining process planning refers to the whole process, and cannot be judged by the nature of a process and the processing of a surface. For example, some positioning datums need to be processed very accurately in the semi-finishing stage or even in the rough processing stage. Sometimes in order to avoid dimensional chain conversion, in the finishing stage, semi-finishing of some minor surfaces can also be processed.

When the processing method and processing stage of the surface of the part are determined, the processing of each surface in the same processing stage can be combined into several working steps.

When parts are machined on CNC machine, the processes are generally divided according to the principle of process concentration. The methods of division are as follows:

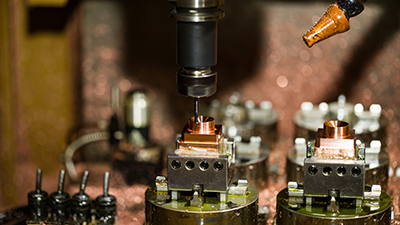

The process completed by the same tool is regarded as a process. This division method is suitable for the situation that the workpiece has many surfaces to be machined. Machining centers often use this method to complete.

The process that can be completed by one clamping of the part is regarded as a process. This method is suitable for the part with few processing contents. In the premise of ensuring the processing quality of the part, all the processing contents can be completed in one clamping.

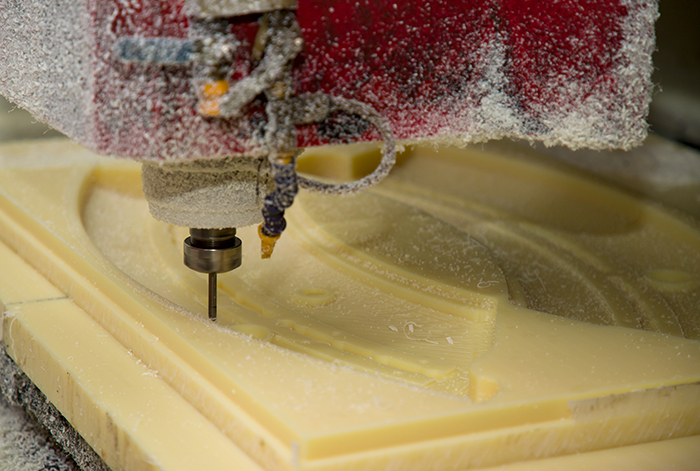

Take the part of the process completed in roughing as one process, and the part of the process completed in finishing as the other process. This division method is suitable for parts that have strength and hardness requirements, need heat treatment or parts with high precision requirements, need to effectively remove internal stress, and parts with large deformation after processing, and need to be divided according to roughing and finishing.

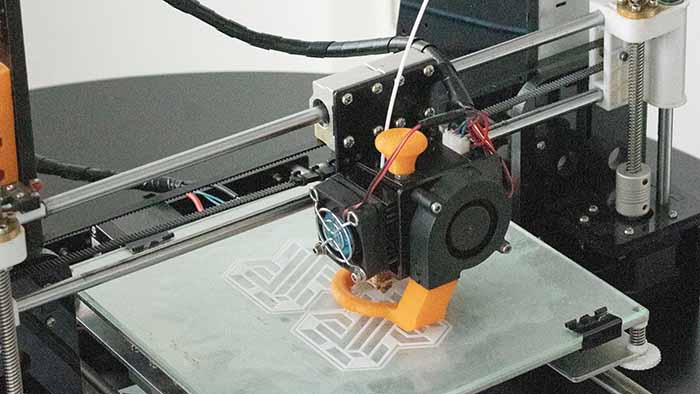

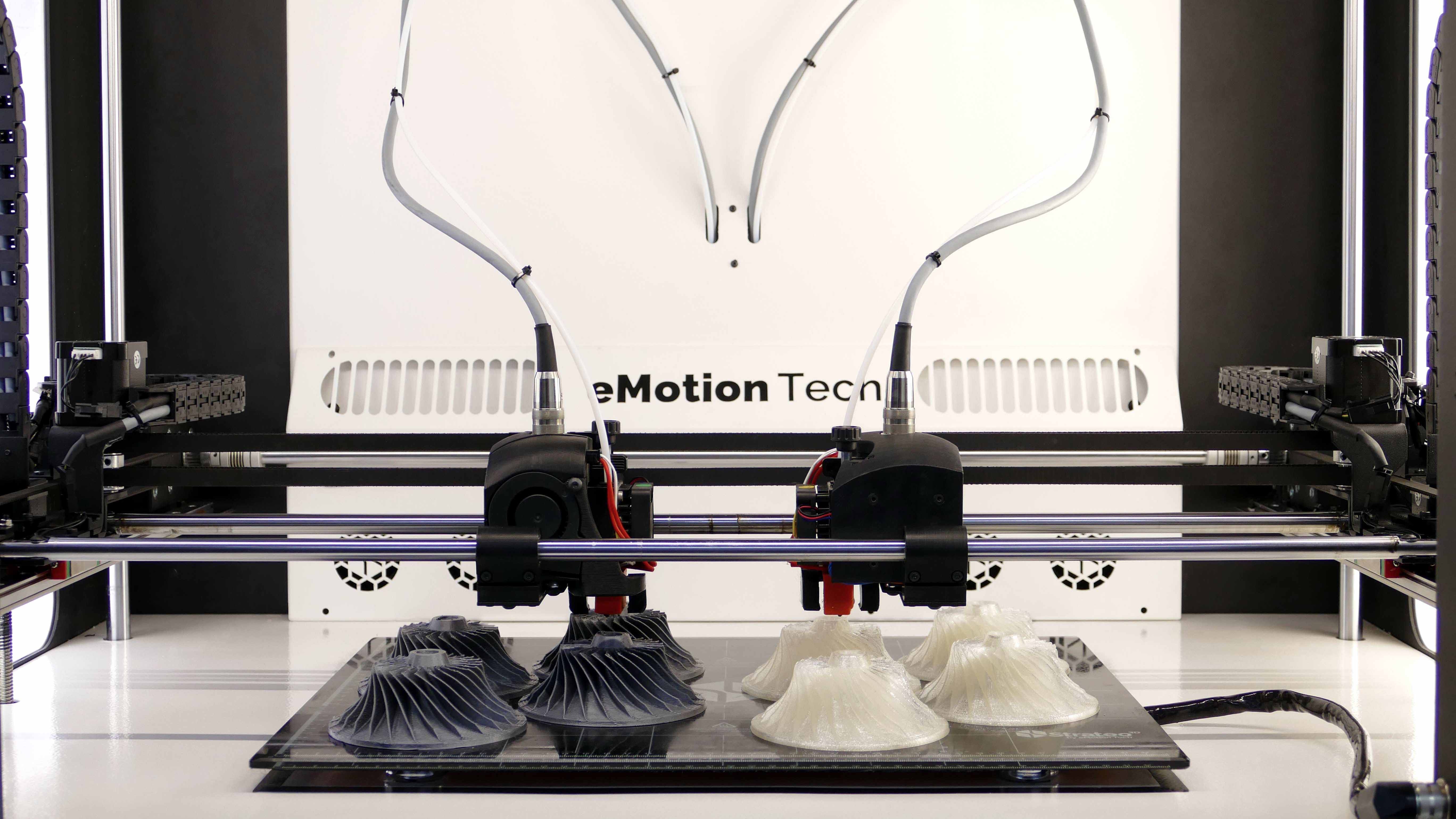

If your rapid prototypings or functional parts need CNC machining, please contact Mastars, we will develop the best solution for you, provide you with products that exceed your expectations and one-stop service.