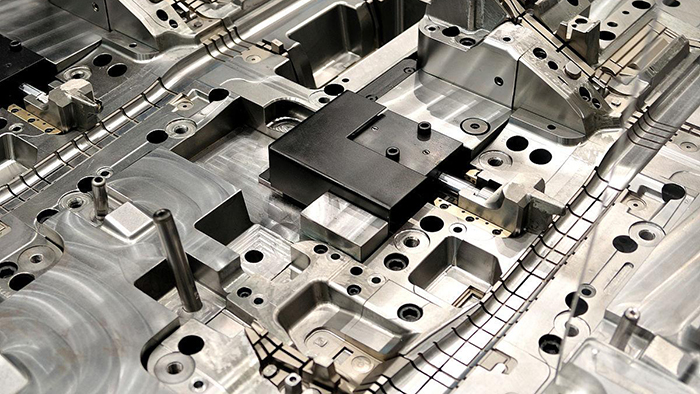

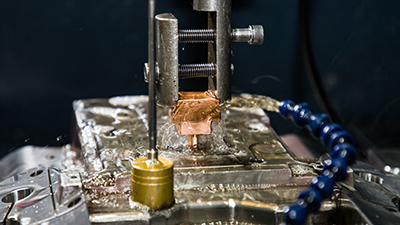

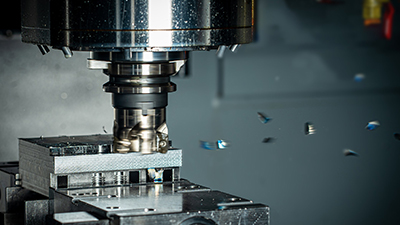

Mastars die castings have been developing zinc and aluminum cast components for over 20 years. Refinements in the alloys and the process have expanded our applications to most market sectors. Size, shape, thickness, strength, and precision combine to offer designers unsurpassed qualities in performance and visual aesthetics.

CHART SOURCE: Mastars

CHART SOURCE: Mastars

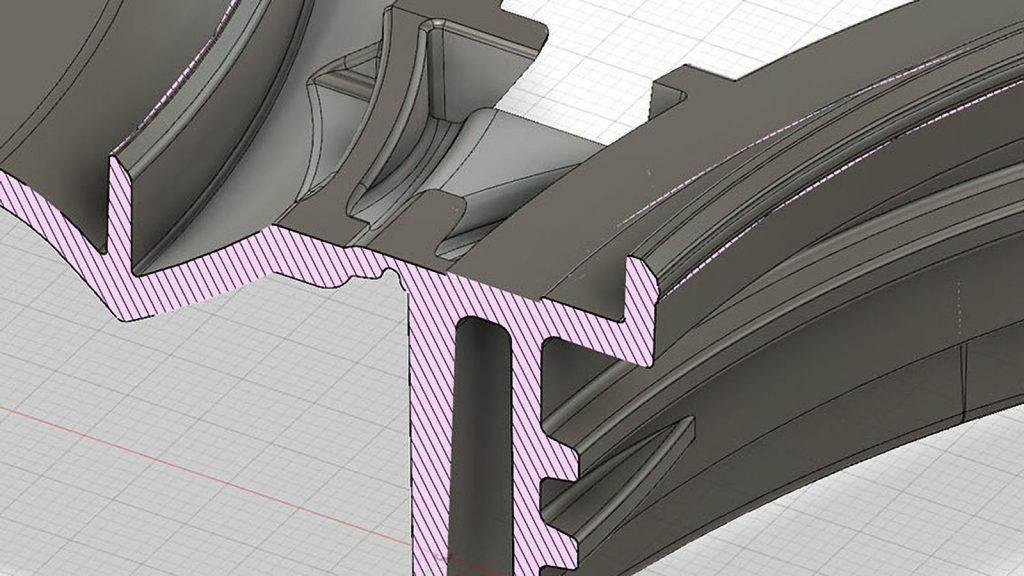

For the first time, Honda Japan has made public a large-scale production facility that realizes one-piece molding of body parts from aluminum. This equipment can reduce the number of body parts to less than one-tenth, helping to reduce the cost of pure electric vehicles (EVs).

CHART SOURCE: nikkei.com

CHART SOURCE: nikkei.com

Honda will first introduce the technology for new EVs that will go on sale in 2026. Tesla in the U.S. and Chinese companies have already taken the lead in introducing integrated molding technology for parts, and Honda is stepping up its efforts to turn the situation around.

CHART SOURCE: nikkei.com

CHART SOURCE: nikkei.com

In order to achieve the goal of “carbon neutrality” by 2050, Honda is accelerating its electrification business in China, with a lineup of 10 purely electric models by 2027, including the e:N series to be released in 2022 and the new electric brand “Ye” series to be released in 2024. The e:N series will be launched in 2022 and the new electric brand “Ye” will be launched in 2024. By 2035, 100% of sales will be pure electric vehicles.