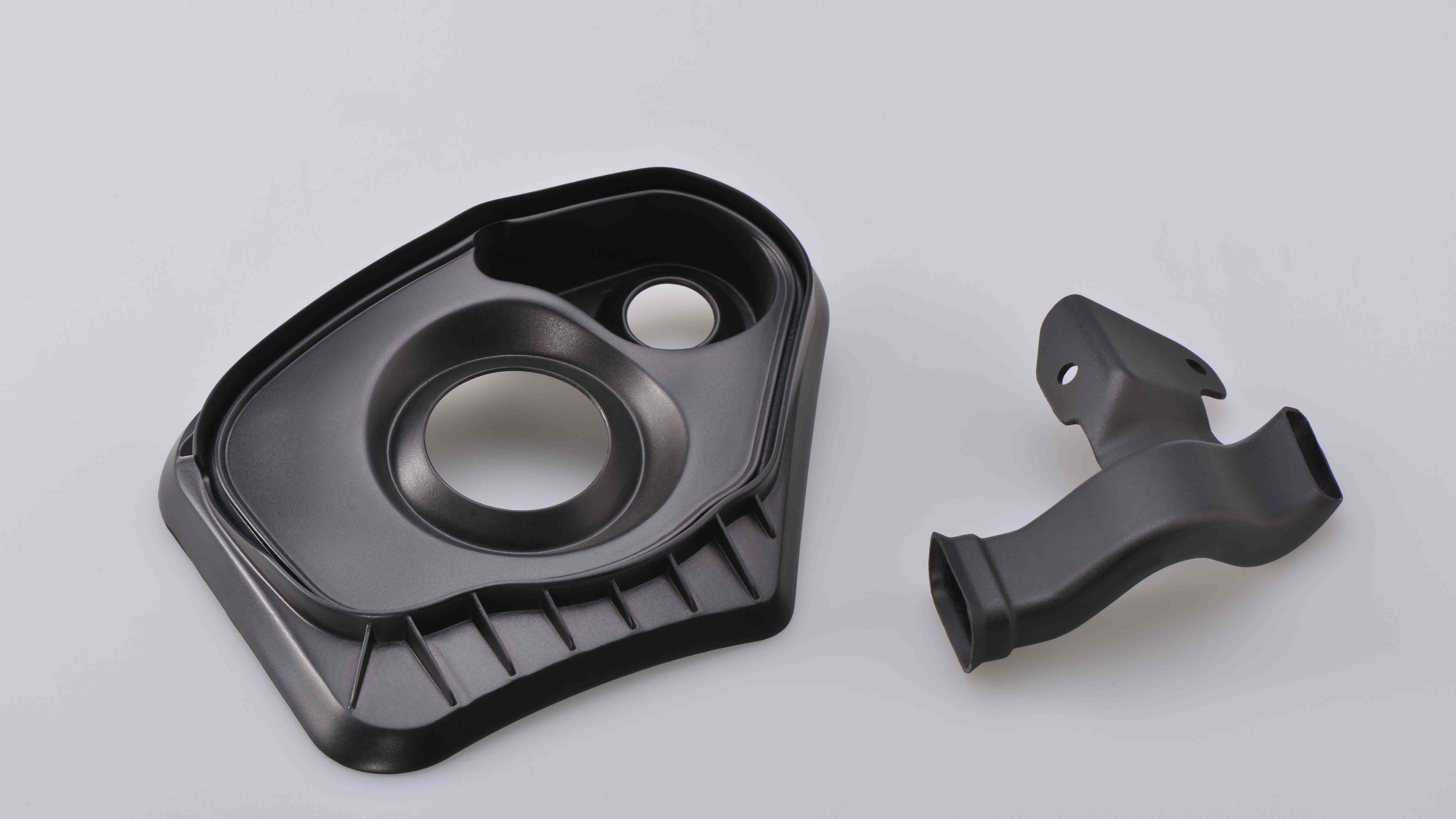

Mastars is a large plastic mold manufacturer specializing in the production and processing of plastic molds and plastic products. It is committed to providing professional injection molding and plastic mold manufacturing,custom metal stamping, rapid cnc services.

Plastic raw material processing process is mainly molten rubber particles, flow, shaping and cooling into finished products, is a process of heating and then cooling, is also the process of plastic from the particles to change to different shapes, the following will be on the different stages of the perspective to explain the processing process.

1. Melting

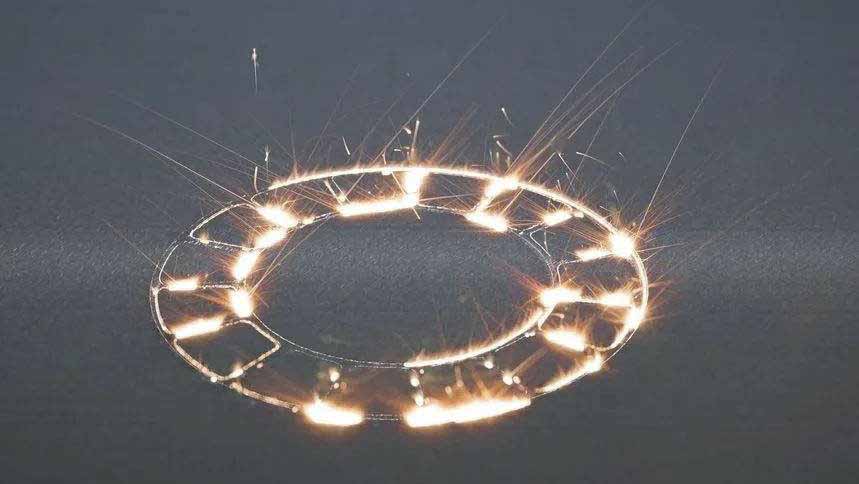

The device heater (Heater) allows the raw material particles to gradually melt into a fluid flow, mainly with different raw materials suitable for temperature adjustment, adjusting the temperature will tend to make the raw material flow faster, can increase efficiency but not necessarily guarantee the yield, must achieve the right balance.

Another good effect and the characteristics of PP cracking in the presence of high heat, it is best to let the raw material flow smoothly to the die head when producing, in order to avoid underfilling or reflux phenomenon, reflux means that the raw material flow is faster than the output rate, and finally will cause the average flow efficiency to increase equal to the MFR, is one of the methods available for processing, but also cause the MFR distribution is not normal may lead to increased instability, resulting in defective rate This is one of the methods available to the process.

But PP finished products because of the application of the relationship is not a high degree of dimensional precision of the product, so the impact is not too big.

2、Screw

The majority of PP processing is driven by the screw mobility, so the design of the screw is very influential, the size of the diameter affects the output, the size of the compression ratio affects the pressure value also affects the output and the effect of the finished product, which also includes a variety of materials (masterbatch, additives and modifiers) of the mixing effect.

The flow of raw materials mainly depends on the heater, but the friction of raw materials will also produce frictional heat to accelerate mobility, so the screw compression ratio is small to drive the flow of small, the speed must be increased to cause frictional heat must be more than the compression ratio of the screw.

Therefore, it is often said that there is no master in plastic processing, and the person who understands the performance of the machine by heart is the master. The heat of the material is not only the heater, but also the frictional heat and the choking time must be taken into account.

So it is a matter of practice and experience helps to solve production problems and efficiency. If a screw needs to be mixed particularly well, it is sometimes designed as a two-stage screw or a twin-shaft screw and divided into sections with different forms of screws to achieve various mixing effects.

3, moulds or mould heads

Plastic reshaping relies on the mould or mould head, injection moulding products are three-dimensional, moulds are also more complex to consider shrinkage issues, other than flat, strip, needle-shaped continuous product mould head, if the special shape is categorised as shaped, need to pay attention to the immediate cooling and shaping issues.

Most plastic machines are designed like injection syringes, with the extrusion force driven by the screw causing significant pressure at the small outlet, increasing productivity. When the mould head is designed as a flat surface, how to make the raw material evenly distributed across the surface, the design of the hanger mould head is very important, and a sophisticated press will increase the amount of gill type help to stabilise the supply of raw materials.

4. Cooling

Injection moulds are designed to cool the raw material in addition to the sprue gate. In the case of pressed moulds, the cooling effect is achieved by means of cooling water channels in the rollers, except for air knives, cooling water directly on the blowing bag, and hollow blowing air.

5、Extension

Finished products and then processing extension will enhance the effect, for example, packing tape by the front and rear roller drive rate is not the same that causes the extension effect, the finished product with the extension of part of the tensile strength to strengthen not easy to tear off, but the horizontal is very easy to tear. Molecular weight distribution will also affect the extension of the effect of high-speed production, all pressed out of the finished product, including fibres have varying extension, vacuum and pressure hollow forming can also be regarded as another form of extension.

6、Shrinkage

Any raw material has the problem of shrinkage, shrinkage from thermal expansion and contraction and the formation of crystallization caused by internal stress.

Generally speaking, thermal expansion and contraction is easier to overcome, can be in the processing to extend the cooling time, continuous pressure can be good, crystalline raw materials than non-crystalline often have a greater difference in shrinkage, in terms of PP about 16 parts per thousand, but ABS only about 4 parts per thousand, the difference is very large part of the mould to overcome, or often add to reduce the shrinkage rate of additives to overcome, pressed out of the flat plate is often added to improve the neck shrinkage of LDPE. LDPE is also often added to pressed flat sheets to improve neck shrinkage.

Mastars Industries CO., LTD

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210690

Mobile: +86 181 0029 4997

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China