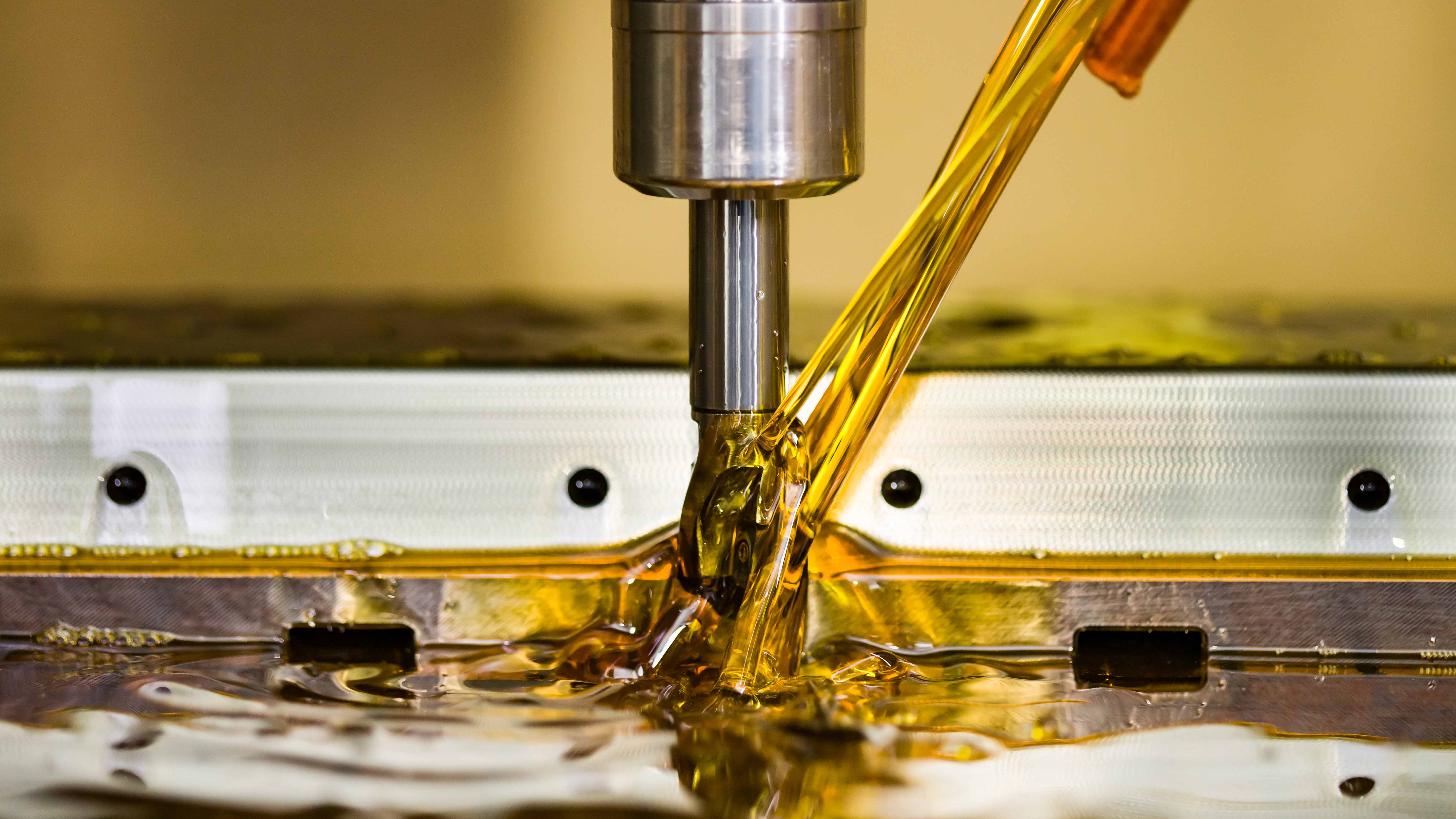

In CNC milling, vibration may occur due to the limitations of cutting tools, tool shanks, machine tools, workpieces or fixtures. To reduce vibration, some strategies need to be considered. 3D printing /rapid prototyping service

CNC machining/custom metal stamping

c) The circular blade milling cutter guides most of the force upward along the spindle, especially when the cutting depth is small. In addition, the 10 ° milling cutter transmits the main cutting force to the spindle, thereby reducing the vibration caused by the long tool overhang

5) Light weight milling cutter is advantageous, for example, milling cutter with aluminum alloy cutter body

Using Coromant capto ® The modular tool holder system can assemble the required length of tools while maintaining high stability and minimum jumping.

6) If the spindle speed exceeds 20000 rpm, use dynamically balanced cutting tools and tool shanks

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210690

Mobile: +86 181 0029 4997

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China