Automobile production needs a high degree of automation, high efficiency, low cost and quality consistency, which seems to have many "gaps" with the current development level of 3D printing. Therefore, the development status and future trend of 3D printing in automobile manufacturing need to be understood in combination with the characteristics of 3D printing technology.|3d rapid printing service|Customized 3D Printing Service

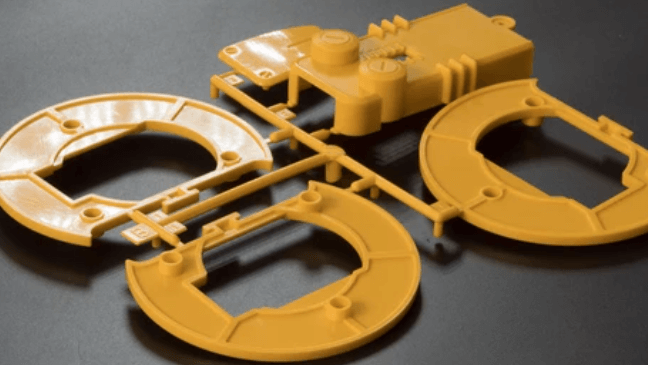

On the one hand, 3D printing has changed the manufacturing logic. Generally, for the same product, the more quantities produced by traditional manufacturing technology, the lower the single piece cost of the product; For additive manufacturing, the correlation between unit cost and output is independent, which is a factor to be considered when considering scalability. On the other hand, about the complexity of products. Usually, when producing parts through traditional manufacturing technology, the more complex the product is, the higher the cost is, and the enterprise needs very expensive investment (including new molds, or even new equipment to realize); For additive manufacturing, the correlation between part complexity and cost is also independent, and the complexity of part geometry usually does not bring additional manufacturing costs.

For automobiles, although automobile production tends to develop to smaller batches, the current combination of 3D printing technology and automobiles is not that the correlation between the cost and output of 3D printing technology is an independent factor, but that 3D printing technology achieves more complex products.|3D Printing Service