Subvert the traditional mode, 3D printing additive manufacturing makes more "possible" become "reality"

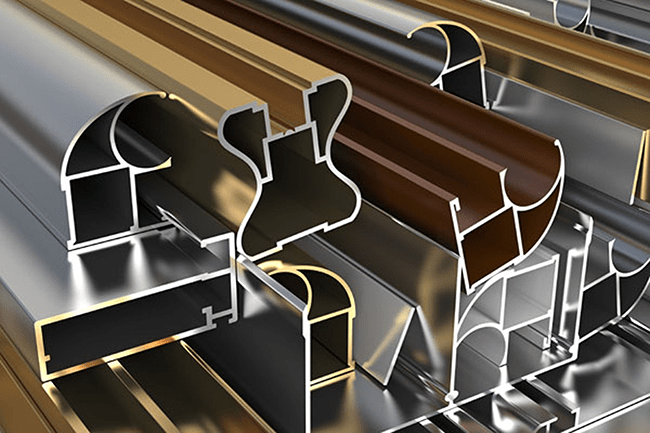

Over the years, the breakthrough of new technology and new process has promoted the manufacturing industry to make great progress, but it is still not enough to fully meet the manufacturing of parts with complex structures and the emerging personalized needs. Mastars provides rapid CNC services, rapid prototyping services, and custom metal stamping

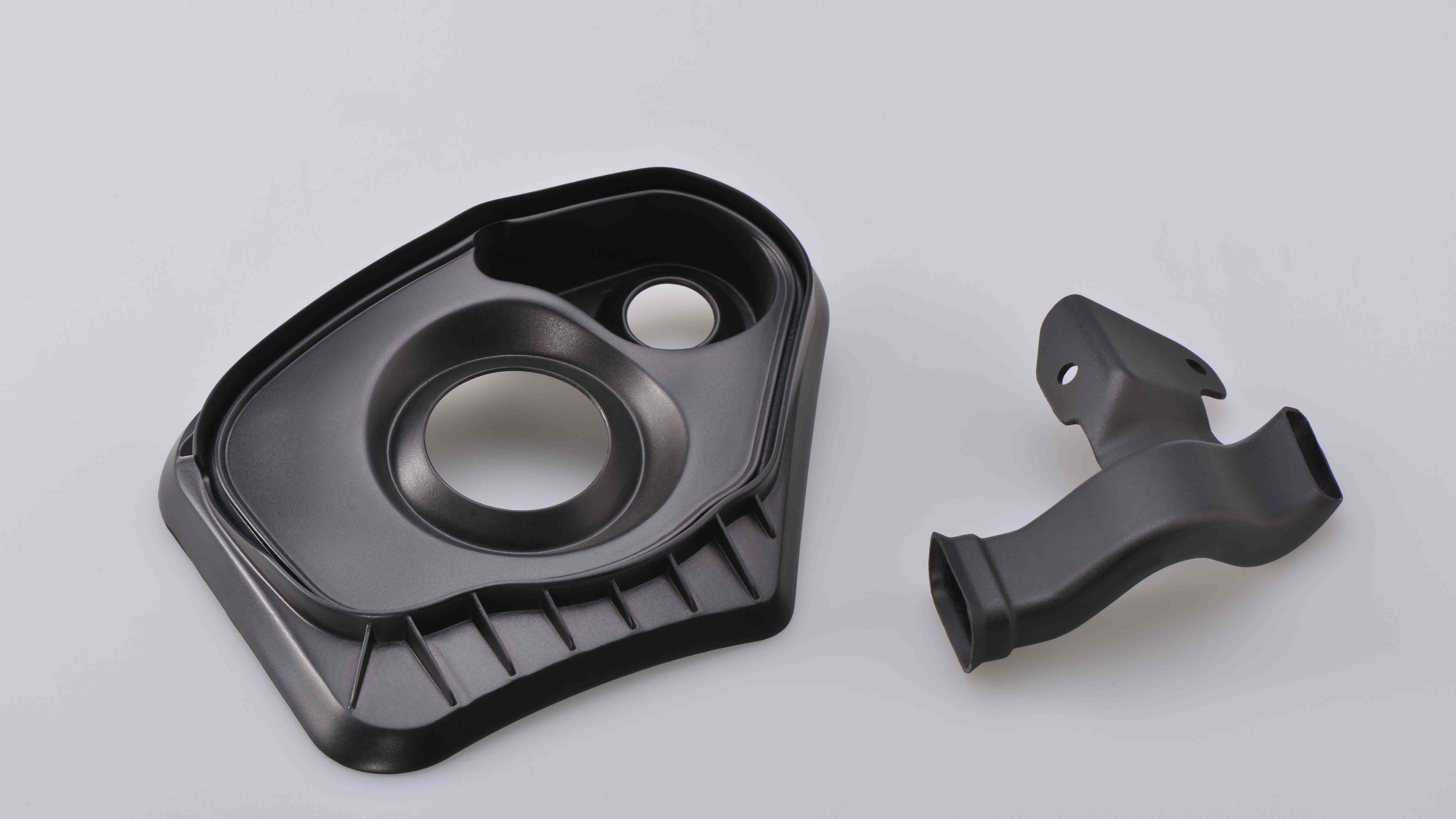

The traditional production mode is similar to chef food carving. The more unique and complex the design, the more difficult it is to present. Take aeroengine turbine blades as an example. According to the traditional design process, it often takes a year or more from design to finished products, which is enough time for astronauts to complete several space missions.

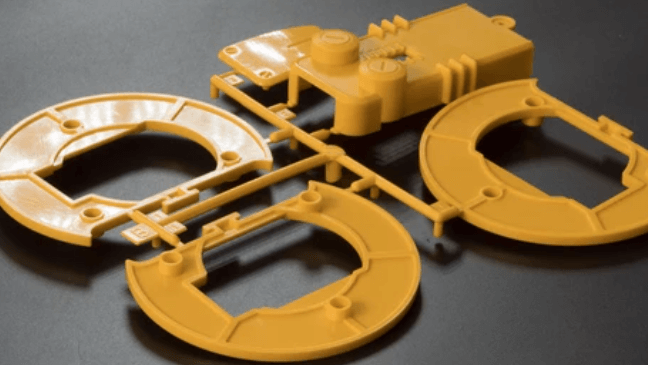

Additive manufacturing is a disruptive manufacturing technology innovation. The principle of additive manufacturing is like milking oil for cakes. Through the stacking of materials layer by layer, the target parts with any shape and structure can be easily made. The combination of additive manufacturing and generative design can eliminate the constraints of traditional production processes, and make the manufacturing industry truly realize the freedom of design and manufacturing.

The generative design of additive manufacturing accelerates the R & D iteration of products and greatly shortens the development cost and cycle of new products and processes. The same aero-engine turbine blades can be completed in only a few weeks through additive manufacturing, which greatly improves the production flexibility of manufacturing enterprises. Additive manufacturing has turned the increasingly strong small batch and personalized demand in the digital era from conception to reality.

Different from the well-known reduced material and equal material manufacturing technologies, additive manufacturing only needs a printing machine to complete the whole manufacturing process, so it can reduce the dependence of production enterprises on the supply chain, which will undoubtedly have a far-reaching impact on the manufacturing industry that has experienced the difficulties of the supply chain in recent years.

There is no doubt that additive manufacturing will create more possibilities for the development of manufacturing industry. The vigorous development of digital technology has brought more stable equipment, more kinds of materials and more intelligent generative design software to additive manufacturing, fully releasing the potential of additive manufacturing. Mastars can provide customers with end-to-end additive manufacturing solutions from design to finished products, and support many mainstream additive manufacturing technologies to truly bring sustainable competitiveness to customers.

Now, additive manufacturing is constantly exploring new application boundaries with the help of digitalization. From scientific research aviation to daily life, from precision components to biomedicine, additive manufacturing has extended to all aspects of society, and with its unique advantages, it has continuously unlocked new fields, opening up the imagination space of "everything can be printed" for the manufacturing industry.