Network segmentation is one of the most effective methods to secure IoT devices in manufacturing. By dividing networks into smaller, isolated sections, manufacturers can reduce cyber risks, limit attack pathways, and ensure smoother operations during security incidents. This approach is especially important for IoT devices, which often lack strong built-in security.

For Australian manufacturers, network segmentation also simplifies compliance with local regulations, secures supply chains, and integrates seamlessly with advanced production systems. By adopting these strategies, manufacturers can protect sensitive data, reduce downtime, and maintain operational integrity.

Network segmentation strengthens security by isolating IoT devices and managing network access more effectively. It not only helps prevent threats but also supports better security management and operational stability. Let’s take a closer look at how segmentation limits attack pathways, improves access control, and speeds up incident response.

Network segmentation reshapes how cyber threats can move within manufacturing systems by establishing clear boundaries between different network zones. If attackers breach one segment, they can't easily move into other critical areas. This containment keeps breaches confined to specific segments.

This is particularly useful for IoT devices, which often come with minimal built-in security. By placing these vulnerable devices in isolated segments, manufacturers create a barrier that stops attackers from using compromised IoT sensors as entry points to more critical systems, like production operations or corporate networks.

Segmentation also reduces the attack surface that malicious actors can exploit. Instead of a single, large network they can explore freely, segmentation breaks it into smaller zones with distinct access controls and monitoring. This makes it much harder for attackers to map out the network or locate high-value targets.

Segmentation doesn’t just limit threats - it also enables precise traffic control that’s not possible in flat network structures. Manufacturers can define strict rules about which devices can communicate, how they connect, and even when they’re allowed to do so. This is especially important for managing the vast number of IoT devices in production environments.

Segmented networks also improve visibility. Any unusual activity - like a temperature sensor suddenly sending data to external networks or generating excessive traffic - becomes easier to spot and investigate.

Additionally, segmentation enhances device behaviour monitoring. For example, if a manufacturing robot tries to access financial systems or a sensor operates outside its assigned hours, security teams are alerted immediately. This level of monitoring ensures that any deviation from expected behaviour is quickly addressed.

When incidents occur, segmentation dramatically reduces response times by narrowing the focus of investigations. Security teams can immediately identify which systems or devices are affected based on the compromised segment, avoiding the need for an organisation-wide inquiry.

Segmentation also simplifies threat containment. If malware is detected in one segment - such as IoT devices on a specific production line - administrators can isolate that segment without disrupting the rest of the operation. This keeps other production areas running smoothly, minimising downtime and maintaining productivity.

Recovery is faster too. Segmentation allows teams to identify unaffected areas and use them as a foundation to rebuild compromised segments. This structured recovery process reduces the overall impact of breaches on operations.

Moreover, segmentation supports automated response systems. Security protocols can be set to isolate segments automatically when certain threat indicators appear. This automation is especially valuable in manufacturing, where even brief delays in response can disrupt production schedules. By cutting response times, automated segmentation ensures that operations face minimal disruption during security incidents.

Implementing network segmentation effectively requires a structured approach that aligns with operational needs. A practical way to start is by dividing the network into broad functional zones, gradually refining access controls as visibility into network activity improves. These methods contribute to the security measures discussed earlier.

Zone-based segmentation involves dividing a manufacturing network into separate segments based on device types, operations, and security needs. This approach creates clear boundaries, making it easier to control access and monitor activity across different areas.

When broader zones don’t provide enough precision, microsegmentation offers a more tailored solution. This method enables highly specific security policies for individual devices, based on their unique communication patterns and requirements.

Building on segmentation techniques, the Zero Trust model takes security a step further by continuously verifying every access attempt. This approach eliminates automatic trust based on network location, requiring constant proof of identity and authorisation for every user, device, and application.

Australian manufacturers encounter distinct challenges in IoT security, from navigating strict regulatory frameworks to managing intricate supply chains. Network segmentation offers a practical solution to tackle these issues. Below, we explore how segmentation supports compliance, fortifies supply chains, and integrates seamlessly with modern manufacturing systems.

Australian manufacturers must adhere to rigorous cybersecurity regulations, particularly in sectors critical to infrastructure and data security. Network segmentation plays a key role in meeting ISO/IEC 27001 standards, which many organisations in Australia are required to follow for managing information security.

The Australian Cyber Security Centre (ACSC) highlights network segregation as a core element of its Essential Eight mitigation strategies. By implementing segmentation, manufacturers can demonstrate their commitment to safeguarding systems against cyber threats. This is especially relevant for businesses operating under the Security of Critical Infrastructure Act 2018, which governs critical infrastructure sectors.

Segmentation also supports data localisation, ensuring sensitive information is stored and processed within Australia when necessary. This simplifies compliance reporting and auditing, as the clear boundaries of segmented networks make it easier to track where data resides and how it is managed.

Beyond compliance, network segmentation strengthens supply chain security - a vital concern for Australia's manufacturing sector, which depends heavily on global supply chains. Segmentation adds multiple layers of defence against a variety of threats targeting supply chains.

One notable benefit is its ability to protect against firmware attacks on IoT devices throughout their lifecycle. By isolating different devices and manufacturers within specific network segments, manufacturers can contain potential breaches and prevent them from spreading across the network.

Many Australian manufacturers are adopting vendor-specific network zones to manage third-party access securely. This approach ensures that external partners and suppliers can only access the resources they need, without exposing core manufacturing systems. Regular security checks of these segmented zones help identify weaknesses before they can be exploited.

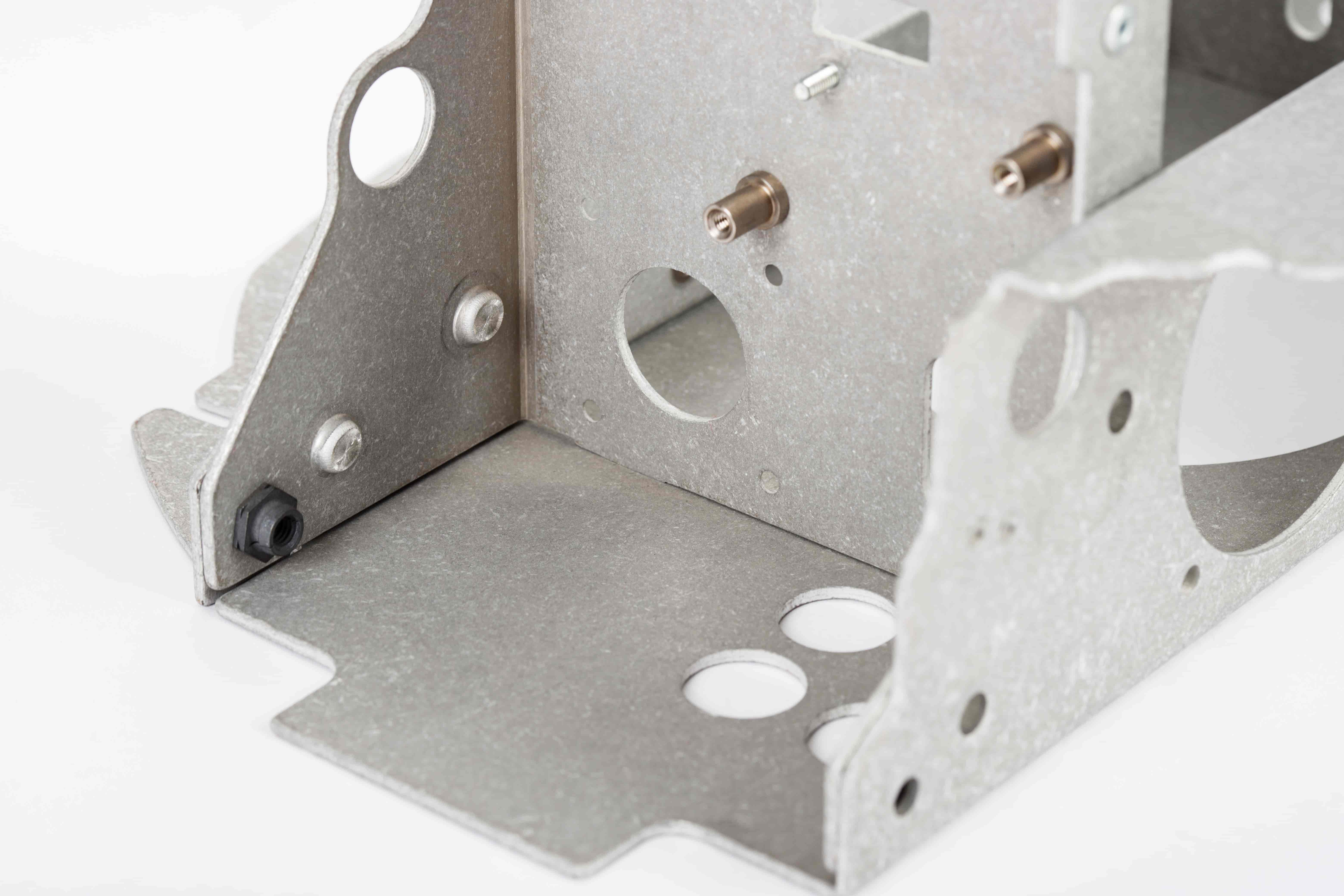

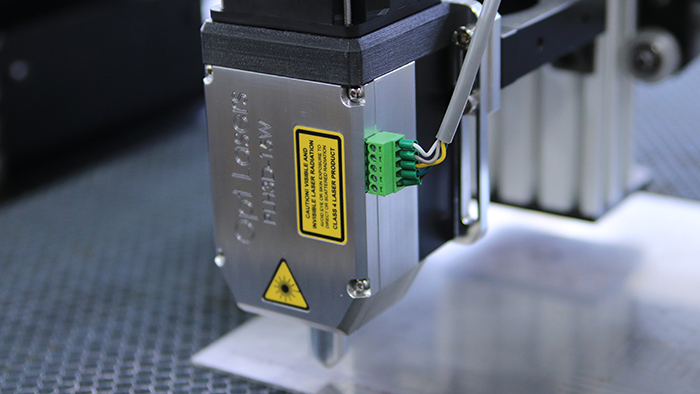

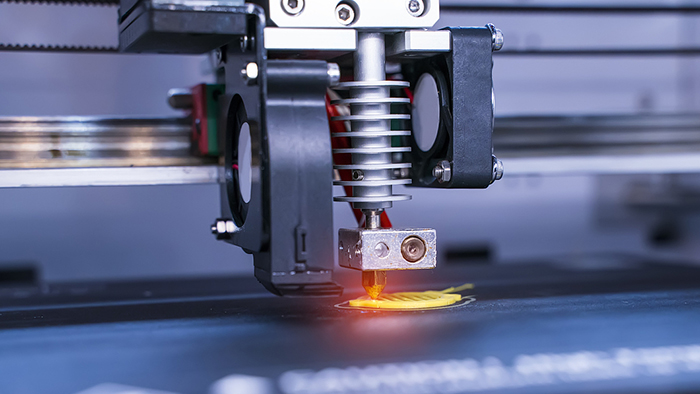

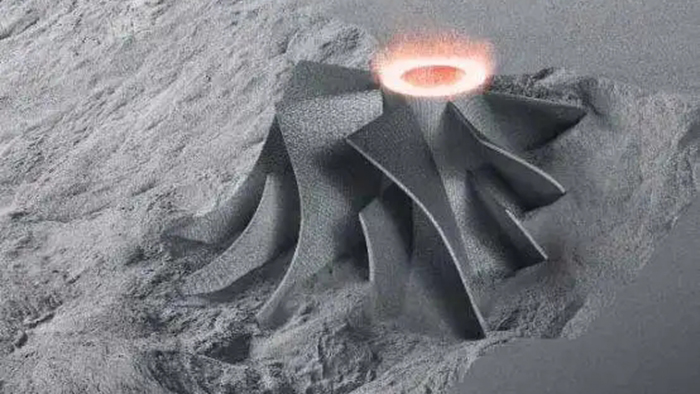

These segmentation strategies also ensure operational data and production processes remain secure without sacrificing efficiency. Mastars' manufacturing services - including CNC machining, 3D printing, injection moulding, and pressure die casting - integrate smoothly with segmented IoT networks, maintaining robust security throughout production.

Mastars brings expertise across industries like automotive, medical devices, and household appliances, aligning perfectly with segmented network designs. Each manufacturing process or production line can operate within its own segment, ensuring that systems for quality control, inventory, and production monitoring are isolated from potential threats.

For example, Mastars' rapid prototyping benefits significantly from microsegmentation. Design data and production parameters can be housed in dedicated network zones, protecting intellectual property while facilitating collaboration between design and manufacturing teams. This is particularly crucial for medical device production, where data protection and regulatory compliance are non-negotiable.

Additionally, Mastars' services extend to supply chain management, integrating with controlled network segments to safeguard tooling data, assembly instructions, and quality metrics. This setup enables real-time monitoring and optimisation across multiple facilities, ensuring security and efficiency go hand in hand.

Network segmentation plays a crucial role in reducing cyber threats targeting IoT devices in manufacturing. By dividing networks into smaller segments, manufacturers can limit the routes available to attackers and keep a closer eye on critical parts of their systems.

Segmenting networks helps restrict the movement of potential threats while sharpening the focus of security monitoring. These steps offer a clear path towards stronger, more actionable security measures.

Network segmentation plays a crucial role in protecting IoT systems in manufacturing. By isolating essential components like industrial control systems (ICS), sensors, and other operational technology (OT) devices from broader networks, it limits the spread of cyberattacks. This is especially important in environments with older or unmanaged devices, which can be more vulnerable to threats.

Breaking networks into smaller, controlled segments helps contain potential threats within a specific area, reducing the overall impact of a breach. For an even more targeted approach, microsegmentation adds an extra layer of protection. It introduces precise access controls at the device level, even in older or flat network setups. This ensures that only authorised traffic can access sensitive assets, providing stronger security for IoT devices in manufacturing settings.

Zone-based division works by splitting a network into broad security zones, aiming to separate large sections and limit potential threats. While this method is simple to implement, it doesn't offer the detailed control required for more precise security measures.

On the other hand, microsegmentation provides a finer level of control by breaking the network into smaller, workload-specific segments. This approach helps restrict lateral movement, making it significantly harder for breaches to spread across the network.

The Zero Trust model takes security a step further by operating on the principle that no entity - whether a user, device, or application - should be trusted by default. It continuously verifies access and enforces strict controls across all areas, including microsegments. When combined, these strategies can work together to bolster IoT security in manufacturing environments.

Australian manufacturers can meet cybersecurity regulations by adopting network segmentation to protect critical systems and sensitive data. By isolating essential networks and restricting access to only authorised users, this method minimises cyber risks and aligns with local standards set by the Australian Cyber Security Centre (ACSC).

Using globally recognised frameworks like IEC 62443, which complements Australia's cybersecurity policies, can also address weaknesses in industrial control systems. This strategy not only makes compliance more manageable but also enhances cyber defences, reducing the likelihood of disruptions in manufacturing operations.