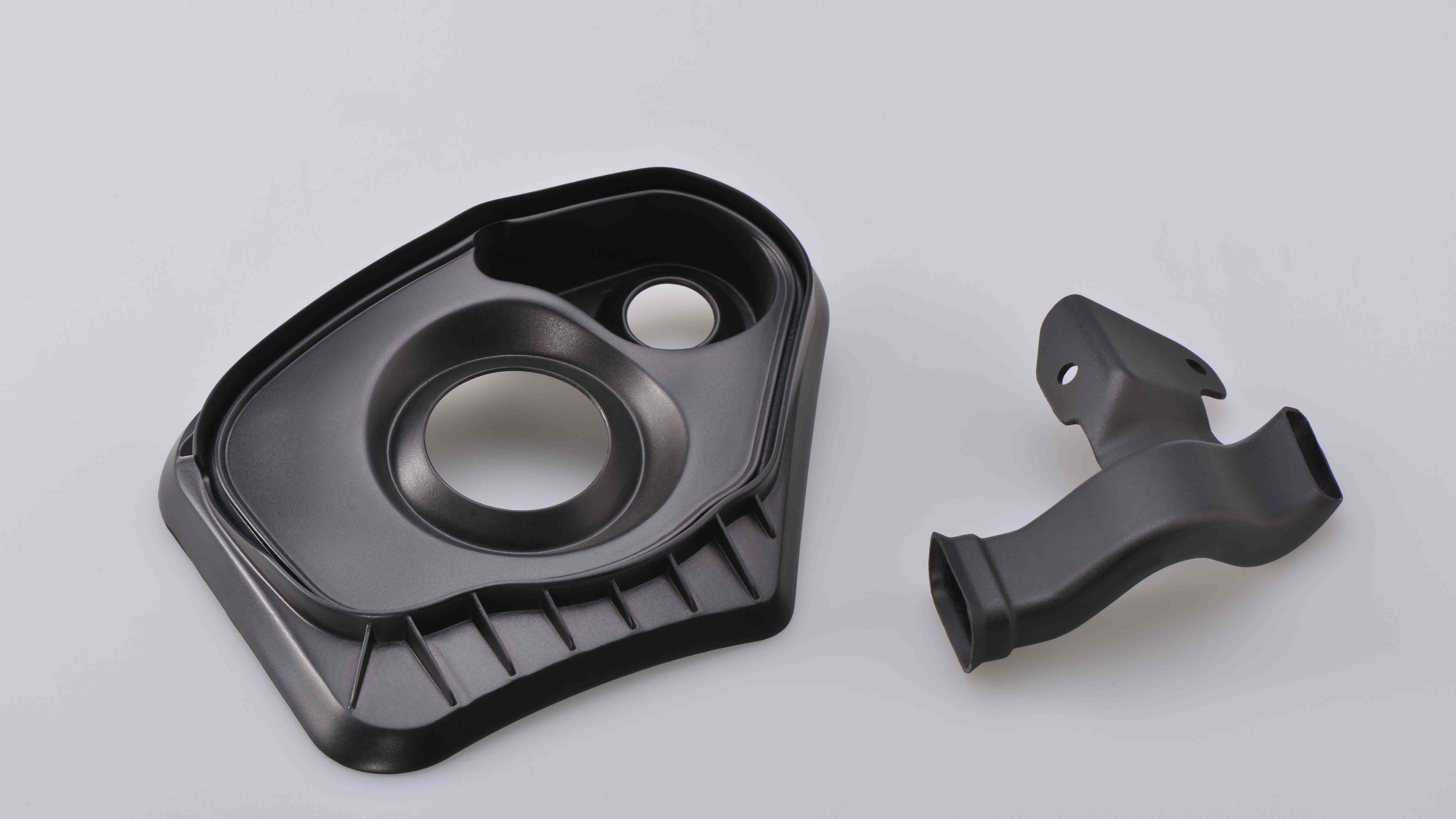

Thin wall parts are indispensable and important parts in industrial production. They have been widely used in

automobile manufacturing, textile, electric power, petrochemical industry, instrument and meter, aircraft manufacturing and other industries; In this issue,

mastars will describe in detail the special content of "what factors affect the processing of thin-walled parts".

Mastars as a

metal prototype maker, provides

rapid sheet metal prototyping,

rapid CNC service

Factors affecting the deformation of thin-walled parts

1. Influence of workpiece material

As the most ideal structural material for thin-walled parts, aluminum alloy has the characteristics of good machinability compared with other metal materials; However, due to the high heat conduction system, small elastic modulus and large yield ratio of aluminum alloy, it is easy to produce rebound phenomenon, especially for large wall thin parts; Therefore, under the same load, the deformation of aluminum workpiece is larger than that of steel material. At the same time, aluminum alloy material has the properties of low hardness, high plasticity and high chemical reactivity. It is very easy to produce chip nodules in its processing, which affects the surface quality and dimensional accuracy of workpiece.

2. Effect of initial residual stress of blank

The deformation of thin-walled parts is directly related to the initial residual stress in the blank. At the same time, due to the influence of cutting heat and cutting force, the materials in contact with the workpiece processing tools produce plastic deformation that cannot rebound; Once the residual stress in the workpiece reaches the permanent deformation, the residual stress will be re distributed in the workpiece, which will cause the permanent deformation of the workpiece.

3. Influence of clamping mode

In processing China, the deformation caused by the clamping and pressing of the fixture on the workpiece directly affects the surface accuracy of the workpiece. At the same time, if the additional stress caused by the improper selection of the action point of the clamping force will also affect the machining accuracy of the workpiece. Secondly, due to the coupling effect between the clamping force and the cutting force, it will also cause the redistribution of the residual stress of the workpiece and cause the deformation of the workpiece.

Factors affecting the machining accuracy of thin-walled parts

1. Easy to deform by force: due to the thin wall of the workpiece, it is easy to deform under the action of clamping you, thus affecting the dimensional accuracy and shape accuracy of the workpiece;

2. Easy to heat deformation: because the workpiece is thin, the cutting heat will cause the thermal deformation of the workpiece, making the workpiece size difficult to control;

3. Easy vibration and deformation: under the action of cutting force, it is easy to produce vibration and deformation, affecting the dimensional accuracy, shape, position accuracy and surface roughness of the workpiece.

As a modern manufacturer of precision mechanical parts, mastars takes CNC machining as the core process, has physical factories and testing equipment, and integrates supporting manufacturing resources such as rapid prototyping, mold and post-treatment to provide customers with rapid proofing, small and medium-sized batch production, manufacturing and trial assembly, so as to truly achieve a one-stop service that saves worry and effort; The enterprise has imported precision machining equipment such as computer gongs, milling machines, lathes and grinders, as well as a technical team with rich experience in non-standard production.

Mastars Industries CO., LTD

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210690

Mobile: +86 181 0029 4997

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China