What is blow molding?

According to different processes, blow molding can be divided into extrusion blow molding and injection blow molding. In the process of extrusion blow molding, the resin is melted and plasticized by the extruder to extrude the tubular parison, and then the parison is placed in the blow molding die, inflated with compressed air, cooled and shaped to obtain a barrel or bottle body with the same shape as the die. The technological process of injection molding and blow molding is that the injection molding machine injects the molten material into the mold to form a tubular parison, then opens the mold to keep the parison on on the core mold, closes the blow molding mold while it is hot and blows compressed air to blow the parison into the shape of the inner cavity of the mold, and then cools and demoulds to obtain the product. Extrusion blow molding is suitable for a variety of plastics and can produce large-scale products, mainly barrels; The wall thickness of injection molding and blow molding products is uniform, which is suitable for the production of large quantities and small exquisite products, mainly bottles.

Injection stretch blow molding

At present, injection stretch blow molding technology is more widely used than injection blow molding. This blow molding method is actually injection blow molding. Only by increasing axial stretch, it is easier to blow and reduce energy consumption. The volume of products processed by injection drawing blowing is larger than that of injection blowing. The volume of the blown container is 0.2 ~ 20L. Its working process is as follows:

1.First inject the parison, and the principle is the same as that of ordinary injection molding.

2.Then turn the parison to the heating and temperature regulation process to soften the parison.

3. Turn to the drawing blowing station and close the mold. The push rod in the core stretches the parison along the axial direction, and blows air to make the parison close to the die wall and cool.

4.Go to the demoulding station to take parts.

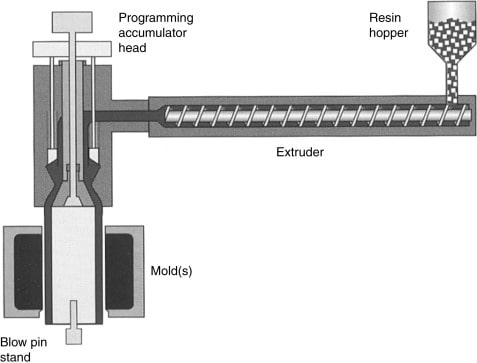

Extrusion blow molding

Extrusion blow molding is the most widely used plastic blowing method in blow molding. It can process a wide range, from small products to large containers and auto parts, aerospace chemical products, etc. the processing process is as follows:

1.First melt and mix the rubber, and the melt enters the machine head to become the tube condition parison.

2. After the parison reaches the predetermined length, the blow mold is closed and the parison is clamped between the two halves of the mold.

3.Blow air, blow air into the parison, blow up the parison, and then form it close to the mold cavity.

4. Cooling products.

5.Open the mold and take away the hardened products.

Mastars are principally engaged in the manufacture of plastic/metal parts business including automotive, industrial and moulds. As manufacturing expertise in China, we provide philosophy, customers benefit from our unique blend of philosophy, customers benefit from our unique blend of quality, reasonable cost, integrated services and flexibiliy.

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210690

Mobile: +86 181 0029 4997

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China