Recently,

Mercedes-Benz has made new progress in reducing carbon emissions! It is working with BASF, Pyrum Innovations, to recycle end-of-life tires using BASF's chemical recycling process.|

rapid prototyping services

"In close cooperation with our suppliers, we are replacing virgin fossil resources with pyrolysis oil, which comes in part from recycled scrap tires supplied by Mercedes-Benz," said Markus Sch?fer, member of the Management Board of the Mercedes-Benz Group of Companies and Chief Technical Officer in charge of Development and Procurement. He said that parts using this technology will enter Mercedes-Benz series production as early as this year.

The technology uses pyrolysis oil extracted from used tires by the pyrolysis company Pyrum Innovations AG, according to the report. BASF combines it with biomethane from agricultural waste to create a recycled material that is comparable in quality to new plastic. The recycled plastic can be certified according to the mass balance method.

The third-party certifier says the supplier has replaced the petrochemical resources needed for the finished product with renewable resources and waste tire pyrolysis oil. The cooperation between Mercedes-Benz and BASF marks the first time that it is possible to use pyrolysis oil from scrap tires in combination with biomethane.

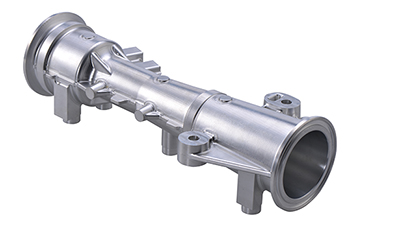

The recycling of secondary materials not only reduces the use of fossil resources, but also reduces the carbon footprint of the resulting plastics. This innovative recycled plastic has the same properties as plastics produced from petroleum. This makes it a "one-stop" solution for rapid production.

At the same time, it meets Mercedes-Benz's high quality requirements, particularly in terms of paintability and crash safety. These characteristics mean that the process has the potential to replace a large number of vehicle components made from virgin plastic.

This year, the EQE and S-Class will be the first Mercedes-Benz models to use recycled plastic made from the aforementioned solution to produce bowed door handles. As part of the front-end structure, this accessory allows for a more even distribution of forces acting on another vehicle in a frontal collision. Upcoming models, such as the EQE SUV, will also be equipped with bow-shaped door handles made of this innovative plastic.

Mercedes-Benz says it will gradually increase the use of this more sustainable recycled material in the future and use chemical recycling in conjunction with biomass balancing methods for further

plastic vehicle components. Mercedes-Benz is working to achieve an increase in the use of recycled materials in its vehicles to 40 percent by 2030.