Recently, BYD topped the list of manufacturers' retail sales with July sales of "162,500 units, up 184.7% year-on-year"!

Mastars manufactures high quality and precision products for the automotive, electronics, medical and outdoor industries. We offer injection molding, rapid CNC services, rapid prototyping services and custom metal stamping.

And before that, BYD's first-half sales volume is also very pleasing - 641,000 units! Tesla's global delivery volume in the first half of the year was 564,000 units, and BYD surpassed Tesla for the first time to become the global champion of new energy vehicle sales.

How to achieve high efficiency and quality of multi-color multi-component injection molding of lights? What are the process pains and difficulties that deserve attention?

01 Matrix lamp strip becomes the new favorite of new energy vehicle lighting

From the early halogen, hernia, etc., to today's LED light source, the innovation of technology has brought revolutionary development to the automotive lamp industry.

LED, OLED, laser light source and other technologies not only make automotive lights more energy efficient, but also have simple structure, versatile form and high light intensity. It can be said that energy-saving light sources such as LED and laser light sources have great potential for application whether in lighting, creating atmosphere or decorative role, and they are the main choice for new energy vehicles.

Compared to the previous single point light source, the matrix light band composed of a large number of light-emitting units is becoming a trend, across the front or rear of the matrix light band supplemented by a variety of color light source not only increases driving safety, but also highlights the new energy vehicle technology, environmental protection, intelligence and other characteristics. The application of new light sources is worthy of attention.

Specifically, the lens material for the automotive lighting industry is mainly optical grade PC/PMMA, optical grade plastic has the advantage of simple technology and low production cost, but compared to glass, high temperature and aging resistance and light transmission are relatively weak, while silicone lenses combine the advantages of glass and optical grade plastic, in terms of light transmission, molding difficulty, aging resistance, etc. shows a more excellent performance.

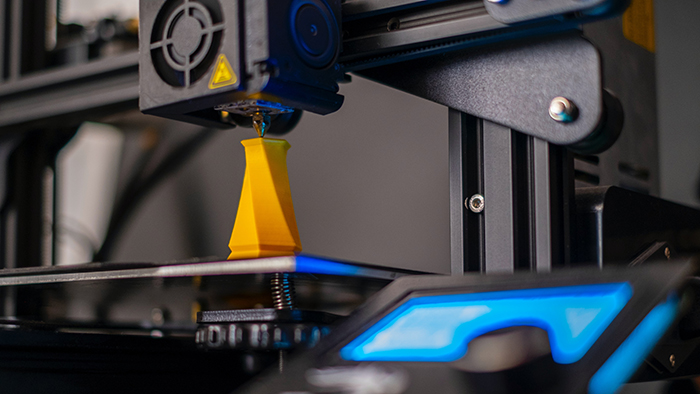

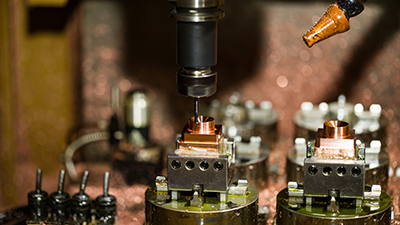

These silicone lenses are usually molded using

multi-color injection molding, and the quality of the mold is very critical to produce a qualified silicone optical part. According to Yu Bin, because of the low viscosity and very good fluidity of silicone, the inserts and the main mold are counted in μm, and even more than 4 μm will still have flying edges, so the polishing of the mold and the processing process put forward higher requirements.