The global

injection molding machine market reached USD 10.79 billion in sales in 2021 and is expected to reach USD 12.6 billion in 2028, at a compound annual growth rate (CAGR) of 1.1% (2022-2028).

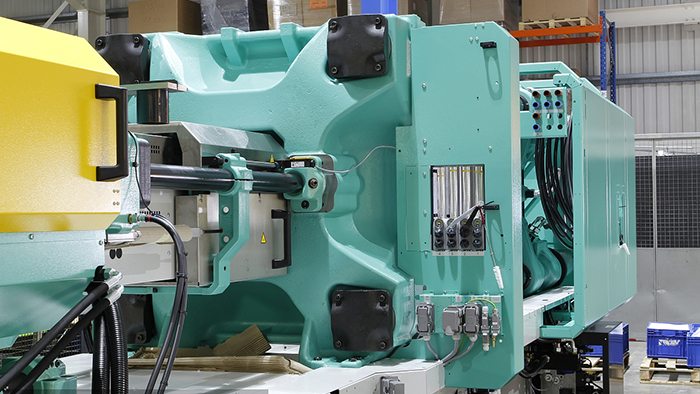

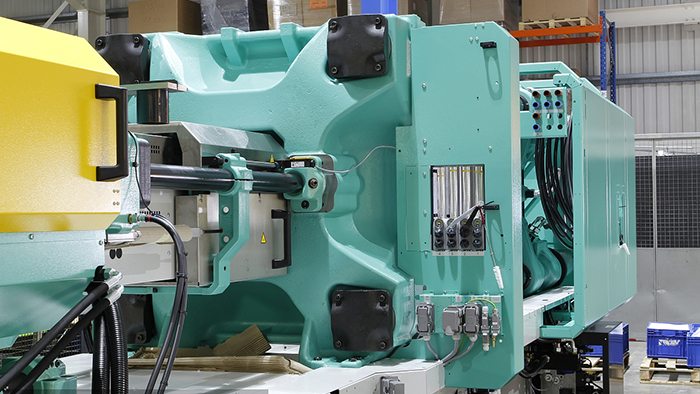

Injection molding machine (injection molding machine or injection molding machine) is the main molding equipment that uses plastic molding molds to make thermoplastic or thermoset materials into various shapes of plastic products. The working principle of injection molding machine is similar to that of a syringe used for injection. It is the process of injecting plastic in a molten state (i.e., viscous flow state) into a closed mold cavity with the help of the thrust of a screw (or plunger), and obtaining products after curing and shaping.

Injection molding is a cyclic process, each cycle mainly includes: quantitative filling - melt plasticization - pressure injection - mold filling and cooling - mold opening and removal. After taking out the parts, the mold is closed again for the next cycle. Injection molding is a cyclic process, each cycle mainly includes: dosing - melt plasticization - pressure injection - mold cooling - mold opening and picking up, and then closing the mold again after removing the part for the next cycle.

The injection molding machine usually consists of injection system, mold closing system, power system, electrical control system, lubrication system, heating and cooling system, safety monitoring system, etc.

The global injection molding machine (Injection Molding Machine) core manufacturers include Haitian International, ENGEL Holding GmbH and KraussMaffei, etc. The top five manufacturers hold about 50% of the global share. Asia Pacific is the largest market in the world, with about 65% of the market share, followed by Europe and North America, accounting for 20% and 5% respectively.