Sheet Metal Prototyping: A Detailed Overview

1. Executive Summary

Sheet Metal Prototyping is the process of creating

physical samples or functional models from sheet metal to validate a product's

design, form, fit, and function before committing to mass production. Unlike

additive (3D printing) or formative (casting) methods, it is a subtractive and formative process. It involves

cutting, bending, and assembling flat sheets of metal into complex

three-dimensional parts. This method is essential for developing enclosures,

brackets, chassis, and countless other components where the final production

part will be made from sheet metal.

2. Core Principle & Key Characteristics

The fundamental

principle is to start with a flat pattern (a 2D representation of the part) and

use a series of controlled deformation and material removal processes to create

the 3D geometry.

Key Characteristics:

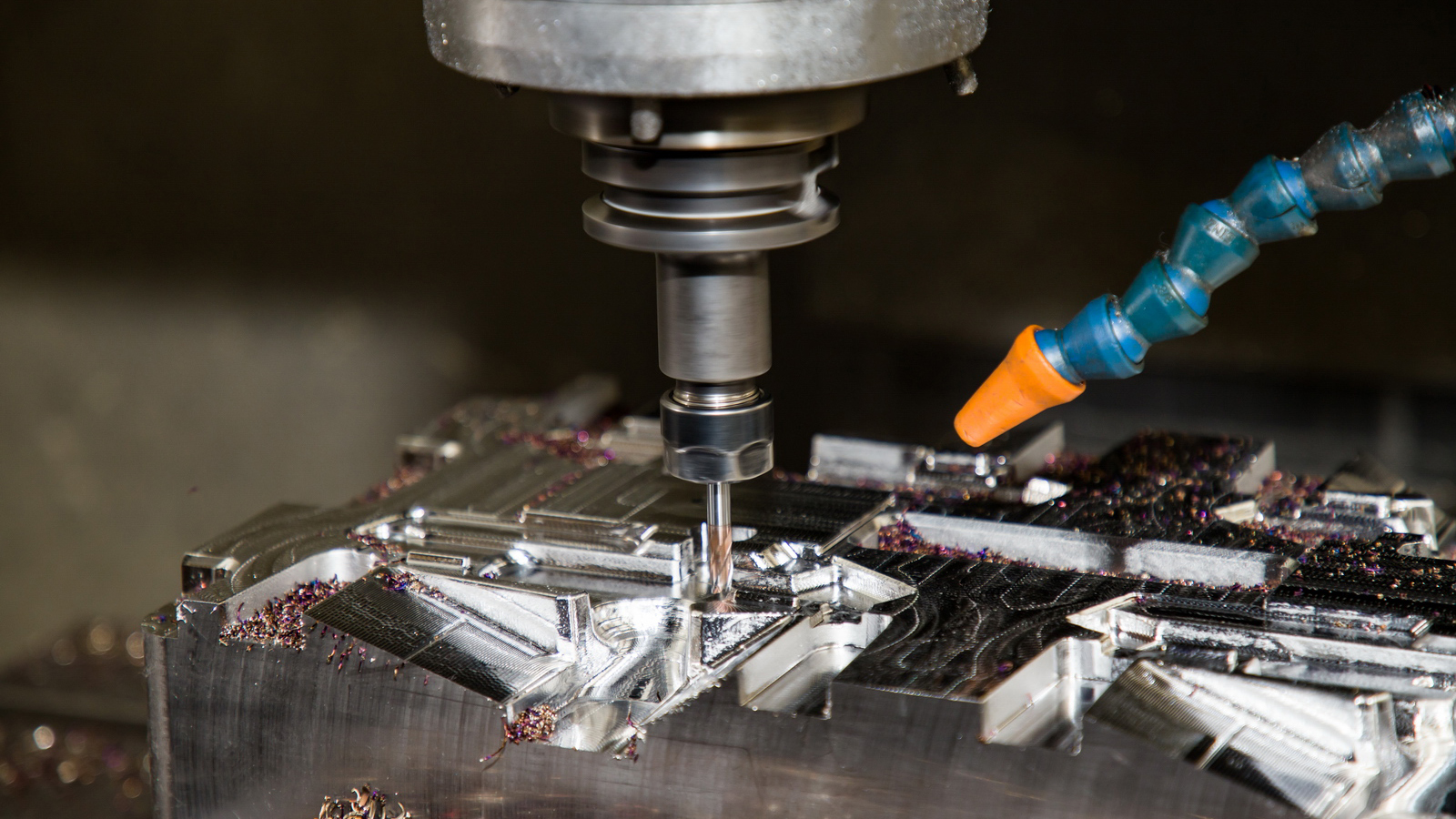

3. Primary Manufacturing Processes

Sheet metal

prototyping relies on a sequence of well-defined processes.

1. CAD & Flat Pattern

Development

2. Cutting & Blanking

This is the process of cutting the 2D profile

from a larger metal sheet. Key technologies include:

3. Bending & Forming

4. Joining & Assembly

5. Finishing & Surface

Treatment

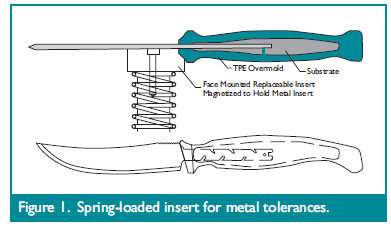

4. Key Design for Manufacturing (DFM) Considerations

Successful sheet metal prototyping requires

adherence to specific design rules:

5. Comparison with Other Prototyping Technologies

|

Feature |

Sheet Metal Prototyping |

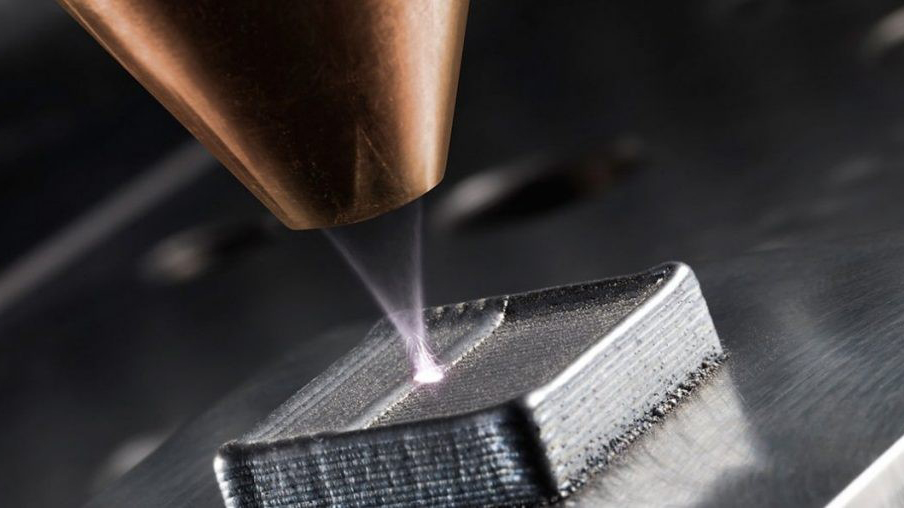

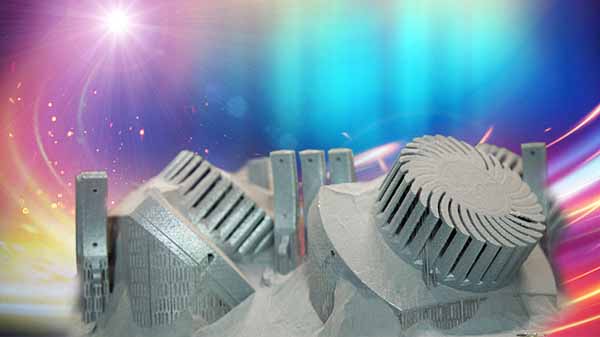

3D Printing (Metal FDM/SLM) |

CNC Machining (from a block) |

|

Best For |

Thin-walled parts, enclosures, brackets,

chassis. |

Highly complex geometries, internal

channels, organic shapes. |

High-strength, high-precision parts from

solid metal. |

|

Material |

Exact production-grade sheets. |

Metal powders (e.g., AlSi10Mg, SS316L) with

different properties. |

Solid blocks of production-grade metal. |

|

Strength |

Excellent, isotropic (same strength in all

directions). |

Can be good, but may be anisotropic (weaker

in one direction) and porous. |

Excellent, isotropic, fully dense. |

|

Lead Time |

Very fast for initial parts (hours/days). |

Moderate (no tooling, but print time can be

long). |

Fast for simple parts, slower for complex

ones. |

|

Cost |

Low to moderate for suitable

geometries. |

High per-part cost. |

Very high due to material

waste (subtractive process). |

|

Surface Finish |

Smooth, formed surfaces. Stair-step effect

from bending possible. |

Rough, "gritty" surface from

sintered powder. Requires post-processing. |

Machine-smooth finish. |

6. Common Applications

Sheet metal prototyping is ubiquitous across

industries:

Conclusion

Sheet Metal Prototyping is an indispensable

method for developing products that will be mass-produced from sheet metal. It provides

a rapid, cost-effective, and functionally accurate way to iterate designs, test

real-world performance, and de-risk the transition to full-scale production. By

understanding the processes and DFM principles involved, engineers can

effectively leverage this technology to bring robust and reliable products to

market.