-

-

The world's largest automobile factory|automotive parts|moldMastars manufactures high-quality and highly accurate products for the automotive, electronics, medical and outdoor indu...

-

-

Material selection precautions of metal stamping die|rapid prototyping servicesMastars provides one-stop industrial manufacturing customization services from prototype to mass production. Rapid sheet...

-

-

The latest award-winning lightweight technology of andoto, Toyota and YanfengMastars provide Precision injection molding The industry covers a wide range of fields, including automobiles, motorcycl...

-

-

How Predictive Analytics Improves CNC MachiningPredictive analytics is transforming CNC machining by using data and machine learning to predict issues, optimise proces...

-

-

Full Guide for Selecting the Right CNC Material|MastarsYou must know that CNC technology is highly repeatable and accurate and offers a better manufacturing process for the pr...

-

-

Pepsi speeds up new bottle development with 3D printed molds|metal 3d printingPackaging design changes can be costly, especially in the bottled beverage industry. PepsiCo's R&D campus in New York St...

-

-

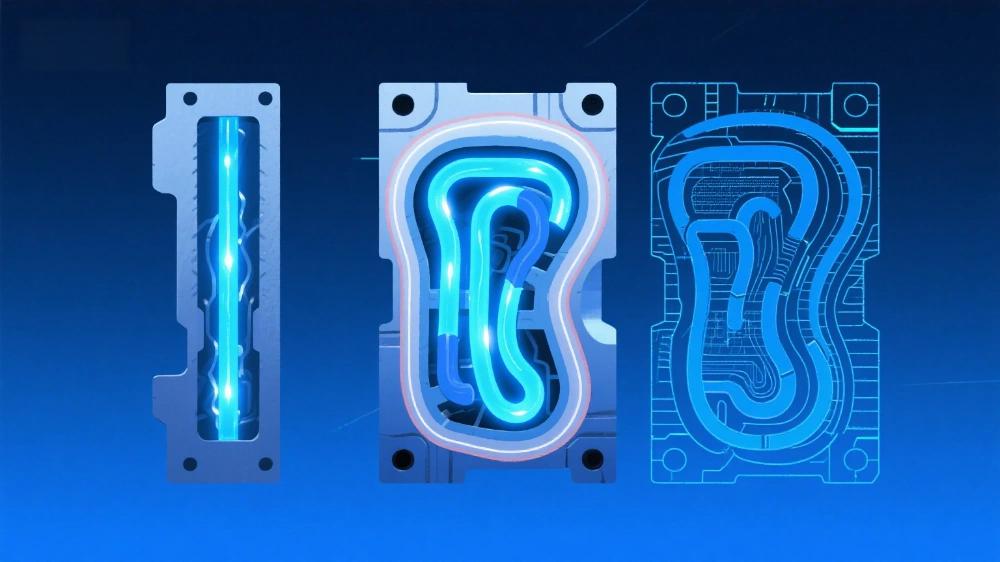

Additive-Manufacturing-Enabled Conformal Cooling High-Pressure Die CastingAdditive-Manufacturing-Enabled Conformal Cooling High-Pressure Die Casting High-pressure die casting (HPDC) has long bee...

-

-

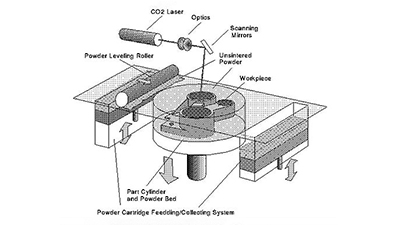

Mastars: Talk about common 3D printing technologies4Mastars' rapid prototyping service can provide various 3D printing prototyping services according to customers' needs, v...

-

-

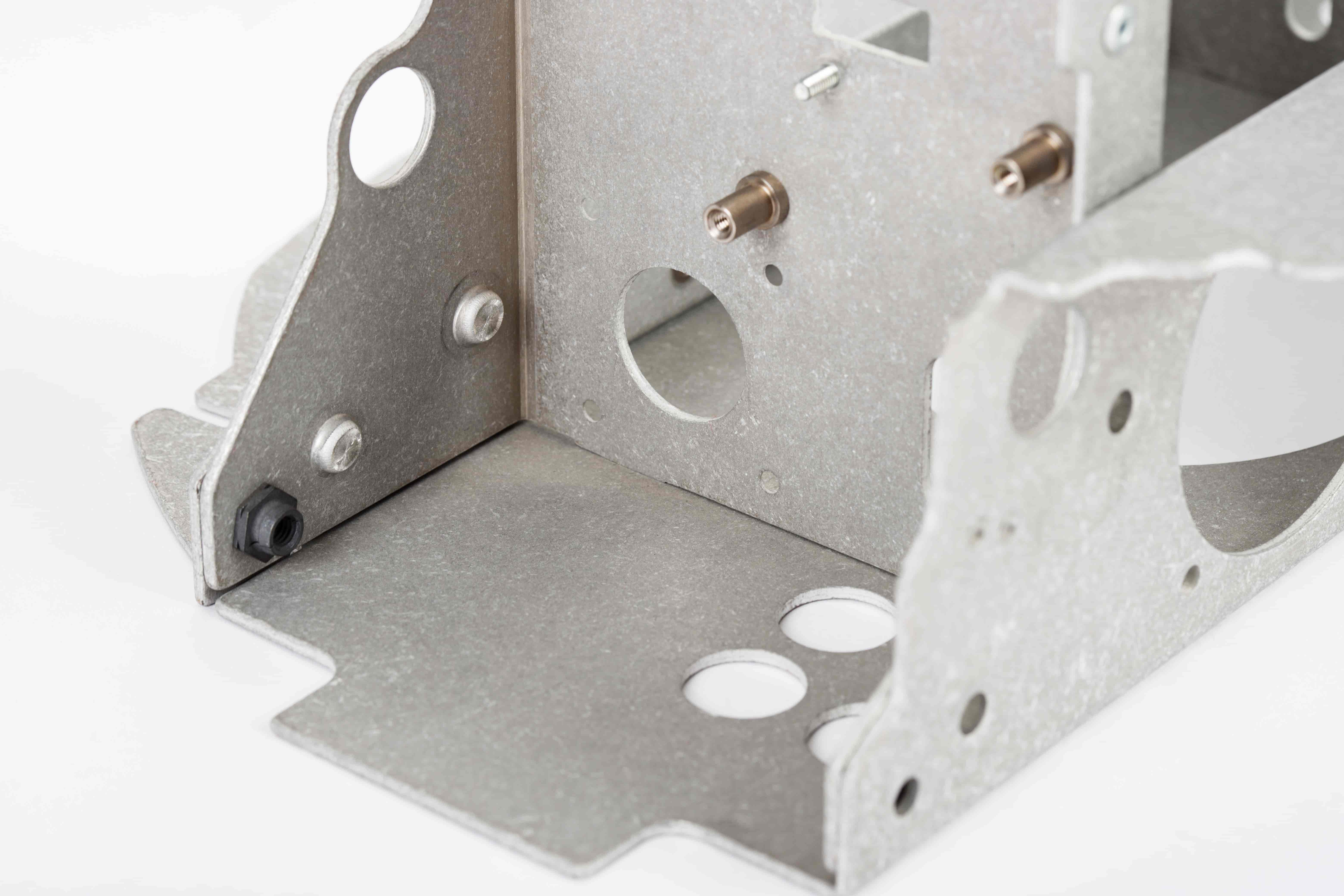

Your Premier Guide to High-Quality Sheet Metal Prototyping ServicesYour Premier Guide to High-Quality Sheet Metal Prototyping Services | Mastars In the competitive world of manufacturing,...

Contact us

- Building 6 , Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City,Guangdong, China (518104)

- marketing@mastars.com

Key Terminologies in Aluminum Extrusion

Aluminum Extrusion: Professional Terminology

Category 1: The Process & Press

|

Term |

Definition & Context |

|

Aluminum Extrusion |

The manufacturing process where an aluminum

billet is forced through a die to create a long, continuous object with a

specific cross-sectional profile. |

|

Direct Extrusion |

The standard method where the billet is

pushed through a stationary die by a moving ram. |

|

Indirect Extrusion |

A less common method where the die moves

and pushes against a stationary billet. Reduces friction and required

pressure. |

|

Extrusion Press |

The main machine that performs the

extrusion, characterized by its tonnage (e.g., a

2,000-ton press). |

|

Container |

The thick-walled, high-strength steel

cylinder that holds the billet and withstands the immense pressure during

extrusion. |

|

Ram |

The large, hydraulically-driven piston that

applies force to the billet. |

|

Stem |

The part that connects the ram to the dummy

block. |

|

Dummy Block |

A reusable disc placed between the stem and

the billet. It seals the container and prevents aluminum from flowing

backward. |

Category 2: Materials & Inputs

|

Term |

Definition & Context |

|

Billet |

A solid, cylindrical log of aluminum alloy

that is the starting material for extrusion. It is cast from molten aluminum. |

|

Alloy |

A specific blend of aluminum and other

elements (e.g., Magnesium, Silicon, Manganese) that determines the material's

properties. Common extrusion alloys are in the 6xxx series (e.g., 6061, 6063). |

|

Temper |

A designation indicating the mechanical

properties achieved through thermal and/or mechanical treatment. Key tempers

for extrusion include: |

|

Homogenization |

A pre-extrusion heat treatment of the

billet to create a uniform microstructure, improving extrudability and

surface quality. |

|

Extrusion Ratio |

The ratio of the cross-sectional area of

the container to the cross-sectional area of the extruded profile. A high

ratio indicates more severe deformation. |

Category 3: The Die & Tooling

|

Term |

Definition & Context |

|

Die |

The tool steel disc with a shaped opening

that determines the profile's cross-section. It is the most critical and

custom part of the process. |

|

Die Stack |

The assembly consisting of the die

itself, the backer, and the bolster, which work

together to withstand extrusion pressure. |

|

Die Orifice / Bearing |

The final, shaped opening in the die. The

length of this opening (bearing length) is critical

for controlling metal flow. |

|

Solid Die |

A die used for producing solid

profiles (profiles with no enclosed voids). |

|

Hollow Die |

A die used for producing hollow

profiles (profiles with one or more enclosed voids). Requires a mandrel. |

|

Porthole Die |

A type of hollow die where the metal is

split into streams that flow around bridges (which hold

the mandrel) and are then welded back together inside the die chamber before

exiting. |

|

Bridge |

The part of a porthole die that supports

the mandrel. It creates weld

lines in the final profile. |

|

Mandrel |

The core component of a hollow die that

forms the inner surface of a hollow profile. |

|

Feeder Plate |

A plate used in conjunction with a die to

help control metal flow for complex shapes. |

Category 4: Profile Types & Geometry

|

Term |

Definition & Context |

|

Profile |

The final, extruded product. Also called a shape or section. |

|

Solid Profile |

A profile with no enclosed voids. |

|

Hollow Profile |

A profile with one or more completely

enclosed voids (e.g., a tube or rectangular pipe). |

|

Semi-Hollow Profile |

A profile that partially encloses a void

but has a narrow, open gap that makes it less rigid than a true hollow. |

|

Cross-Section |

The two-dimensional shape of the profile

when cut perpendicular to its length. |

|

Tongue |

A narrow, protruding feature in the die

that forms a recess in the profile. Tongues are susceptible to deflection and

breakage. |

|

Wall Thickness |

The thickness of the material in the

profile. Maintaining uniform minimum wall thickness is a key design

constraint. |

|

Circle Size |

The smallest circle that can fully enclose

the profile's cross-section. This is a key parameter for pricing and press

capacity. |

Category 5: The Extrusion Cycle & Defects

|

Term |

Definition & Context |

|

Butt |

The portion of the billet that remains in

the container after extrusion. It contains oxides and impurities and is

discarded for recycling. |

|

Breakthrough |

The moment when the aluminum first emerges

from the die orifice. |

|

Extrudate |

The hot, soft aluminum as it exits the die. |

|

Runout Table |

The conveyor system that supports the

extrudate as it exits the press. |

|

Quenching |

The rapid cooling of the extrudate using

air (air

quench) or water (water quench) to achieve the

desired temper. |

|

Stretching |

A post-extrusion operation where the

profiles are stretched (0.5-3%) to straighten them and align the grain

structure, improving strength. |

|

Die Lines |

Fine, longitudinal lines on the profile's

surface, caused by minor imperfections in the die bearing. |

|

Pick-Up |

Surface defects where small particles of

aluminum adhere to the die bearing, causing scratches on the profile. |

|

Weld Lines / Seam Welds |

Longitudinal lines in a hollow profile

where the metal streams were re-welded after flowing around the bridges in a

porthole die. A potential weak point if not done correctly. |

Category 6: Post-Extrusion & Finishing

|

Term |

Definition & Context |

|

Age Hardening (Artificial Aging) |

A heat-treatment process where extruded

profiles are heated for a specific time to increase their strength (achieving

T5 or T6 temper). |

|

Anodizing |

An electrochemical process that thickens

the natural oxide layer on the aluminum, providing superior corrosion

resistance and allowing for coloring. |

|

Powder Coating |

A dry finishing process where

electrostatically charged powder is applied to the profile and then cured

under heat to form a durable, colored coating. |

|

Fabrication |

Secondary operations performed on extruded

profiles, such as cutting, drilling, milling, tapping, and welding. |

|

Mitering |

Cutting profiles at an angle for assembly

at corners. |

【Editor】:Mastarsall rights reserved:https://www.mastars.comPlease indicate the source