Mastarts has advanced SLA, SLS, SLM 3D printing equipment and high-precision 5-axis CNC machines, which can ensure the accuracy and quality of post-processing, and has many years of experience in medical, automotive, aerospace, industrial manufacturing, 3C electronics, mold manufacturing and other industries, as well as more than 20 years of accumulation of rapid prototyping services, we have faster, higher quality, lower cost service advantages. We have the advantages of faster speed, higher quality and lower cost.

CHART SOURCE: Mastars

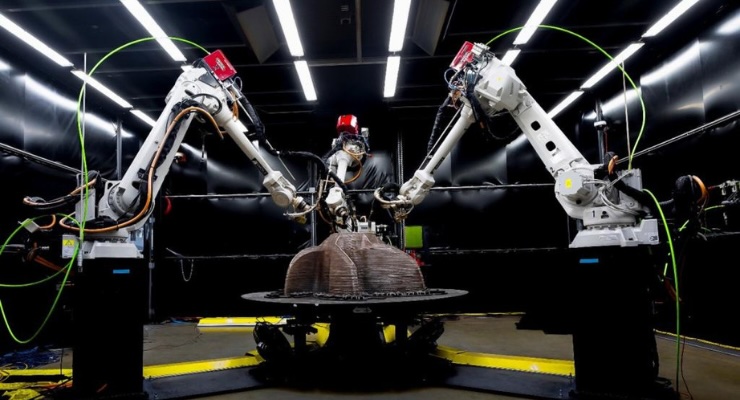

The U.S. Department of Energy's Oak Ridge National Laboratory (ORNL) aims to restore U.S. manufacturing dominance in clean energy, aerospace, and defense by combining 3D printing technology with the powder metallurgy-hot isostatic pressing (PM-HIP) process to drive innovations in large-scale metal parts manufacturing.

The U.S. faces supply chain challenges in supplying large-scale metal parts in excess of 10,000 pounds as traditional casting and forging technologies move overseas. To address this issue, ORNL proposed a solution that combines 3D printing with the PM-HIP process.

CHART SOURCE: 3D Print.com

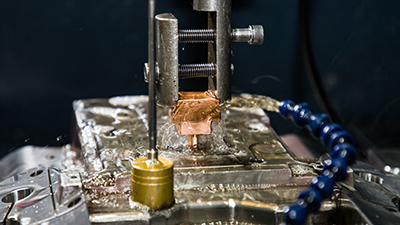

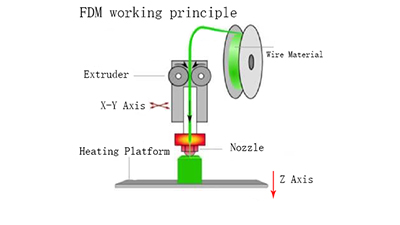

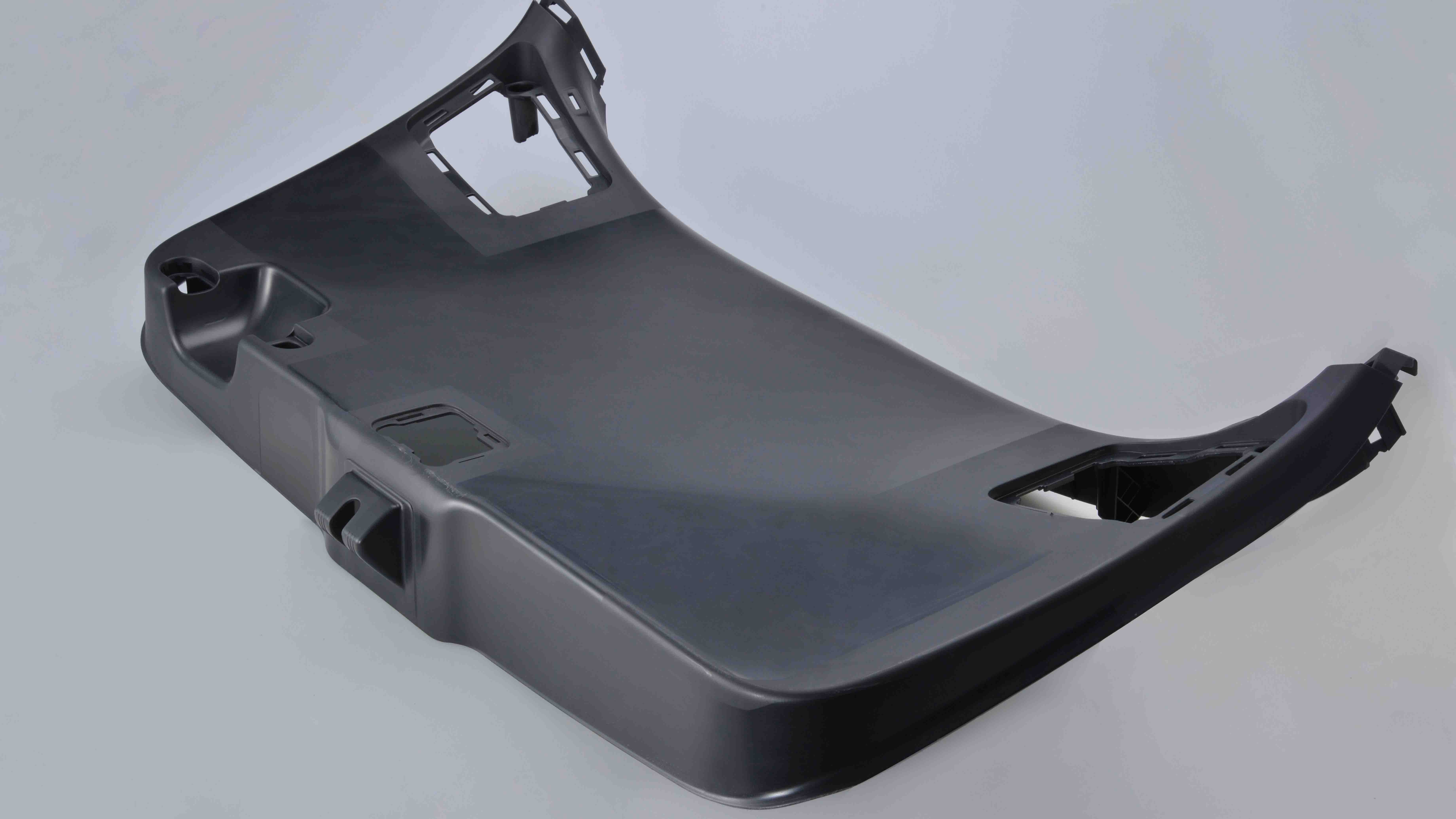

First, 3D printing is used to create complex mold structures, and then the gold powder is densely molded under high temperature and pressure by hot isostatic pressing. This process not only reduces the porosity found in traditional casting, but also supports multi-material design, which is particularly applicable to the demand for high-performance materials in the energy and defense sectors. ornl has also developed computational models to address the volumetric shrinkage of up to 30% of the metal powder during the molding process.

Dimensional accuracy of complex geometric parts is ensured by accurately predicting and adjusting the mold design. Combining experimentation and simulation, the ORNL team improved the reliability and accuracy of the PM-HIP process, enabling the production of high-quality, customized large metal parts. This technological breakthrough is critical to U.S. manufacturing. It reduces dependence on overseas supply chains and increases supply chain autonomy in critical areas such as nuclear energy, hydropower, and aerospace.

Additionally, PM-HIP technology supports an efficient, low-emission energy system that meets U.S. carbon reduction goals and reduces the carbon footprint associated with international transportation through local production.