Mastars is a plastic and metal parts manufacturer, producing and selling: stamping, plastic moulds, stamping parts, plastic parts; providing rapid CNC machining, plastic molds, for electronics, electrical appliances, automotive, office supplies, cosmetics, medical equipment, 3C industries.

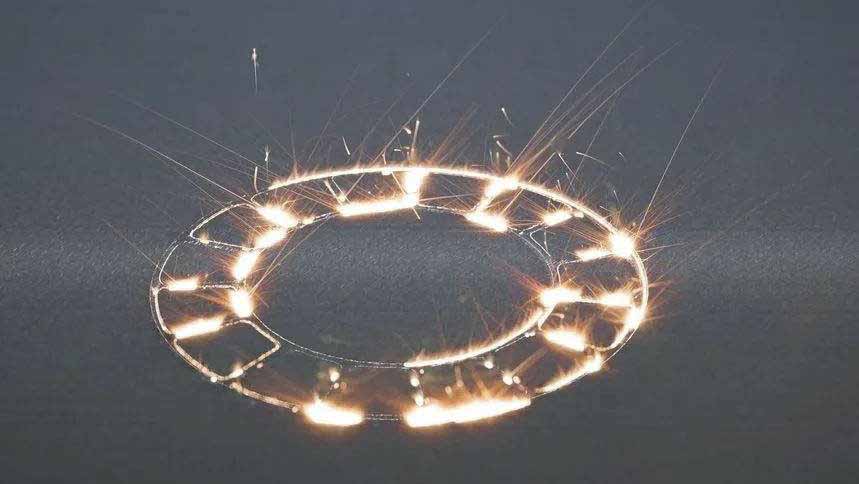

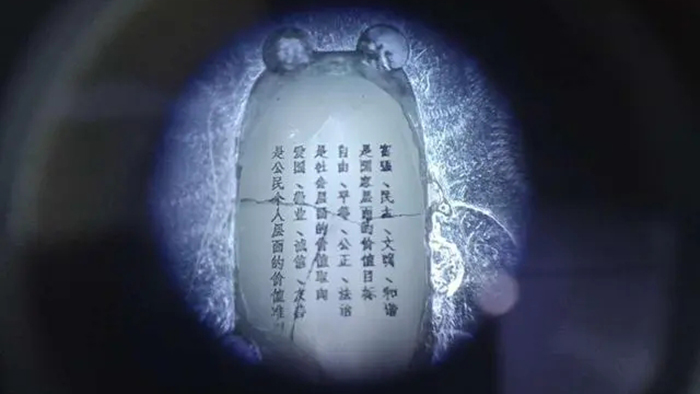

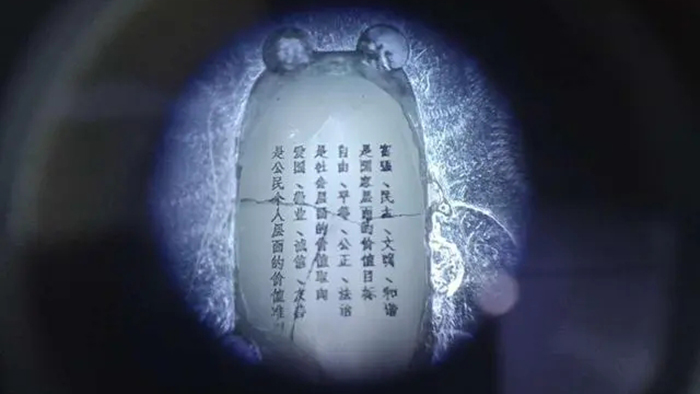

This is the 0.01mm diameter milling cutter developed by Jinzhou, which can realize the milling of 7 letters on a hair and 56 Chinese characters on a grain of rice.

If you look at it with the naked eye, it is ordinary, but if you magnify it 1000 times, you will find that the carbide cylinder of 0.01mm diameter grinds six parts such as the back angle of the end tooth and the spiral groove of the side clearance angle.

Where is the 0.01mm tiny diameter milling cutter used?

This kind of micro precision cutter is very close to the life of the public, and has a close connection with 3C products such as cell phones and computers, and plays an important role in biomedical, optical instruments, automobile manufacturing, aerospace and other fields

In 2021, Jinzhou Company, a subsidiary of China Minmetals, accelerated the rhythm of research and development of 0.01 to 0.04mm miniature milling cutters, and has gone through dozens of programs and countless experiments, successively breaking through the bottleneck of very small edge diameter easy to break, complex structure difficult to grind, high precision requirements difficult to control.