Professional

Terminology in 3D Printing Prototyping

1. Core 3D Printing & Prototyping Terms

|

Term |

Definition |

|

3D Printing |

A process of

creating three-dimensional objects by adding material layer by layer, based

on a digital model. Also known as Additive

Manufacturing (AM). |

|

Additive Manufacturing (AM) |

The broader

technical term for 3D printing; building objects by adding material rather

than subtracting it. |

|

Rapid Prototyping (RP) |

The fast

fabrication of a physical model or part using 3D printing or other

techniques, primarily for testing design concepts. |

|

Prototype |

An early sample

or model of a product built to test a concept or process. In 3D printing, it

can be functional or non-functional. |

|

Iterative Design |

A cyclical

process of prototyping, testing, analyzing, and refining a product design. 3D

printing enables fast iterations. |

|

Part Geometry |

The shape,

structure, and complexity of the 3D model being printed. |

|

Layer Height |

The thickness of

each individual layer of material deposited by the 3D printer; affects

resolution and print speed. |

|

Infill |

The internal

structure of a 3D printed part, usually a grid or honeycomb pattern, which

determines part strength and material usage. |

|

Support Structures |

Temporary

structures printed to support overhanging features during the build process;

usually removed after printing. |

|

Overhang |

A part feature

that extends horizontally or at an angle without underlying support, often

requiring supports. |

|

Print Bed / Build Plate |

The flat surface

where the 3D object is printed; must remain level and properly adhered for

successful prints. |

|

Raft / Brim / Skirt |

Additional

structures printed around or under the main model to improve adhesion or

stability. |

2. 3D Printing Technologies

|

Term |

Definition |

|

FDM (Fused Deposition Modeling) |

A common 3D

printing method where a thermoplastic filament is melted and extruded through

a nozzle, layer by layer. |

|

SLA (Stereolithography) |

A resin-based 3D

printing process that uses a laser to cure liquid photopolymer resin into

solid layers. Known for high detail. |

|

DLP (Digital Light Processing) |

Similar to SLA

but uses a digital light projector for curing resin; faster than traditional

SLA for some applications. |

|

SLS (Selective Laser Sintering) |

A powder-based

process where a laser sinters (fuses) powdered material (usually nylon) to

create solid layers. |

|

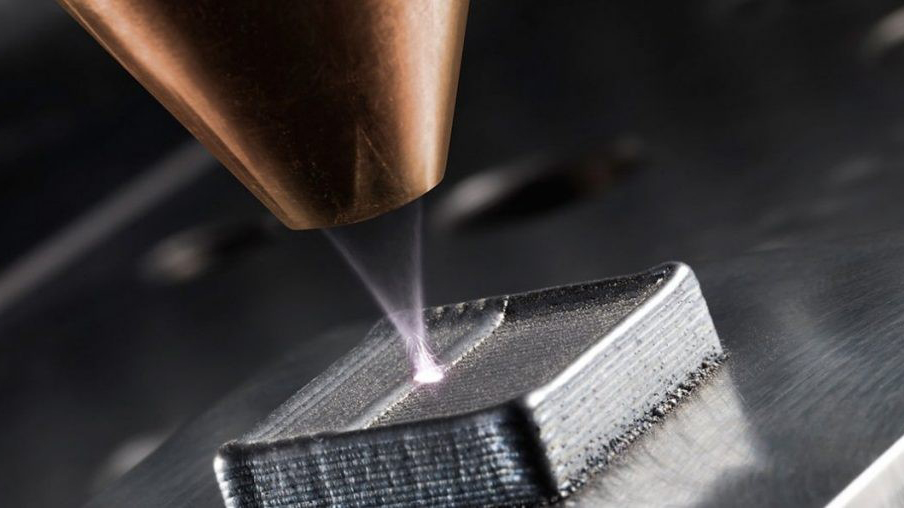

SLM / DMLS (Selective Laser Melting / Direct Metal

Laser Sintering) |

Metal 3D

printing technologies that use lasers to fuse metal powders together, often

used for industrial prototypes. |

|

Binder Jetting |

A process where

a liquid binding agent is selectively deposited to join powder particles

(metal, sand, etc.). |

|

PolyJet |

A high-detail

inkjet-based process that jets layers of liquid photopolymer and cures them

with UV light; capable of multi-material and color printing. |

|

MJF (Multi Jet Fusion) |

A powder-bed

fusion technology (by HP) that uses fusing and detailing agents to produce

functional nylon parts with good detail and strength. |

3. Materials Related Terms

|

Term |

Definition |

|

Filament |

The spooled

thermoplastic material used in FDM 3D printing (e.g., PLA, ABS, PETG). |

|

Resin |

Liquid

photopolymer used in SLA, DLP, and similar resin-based 3D printing processes. |

|

Powder (Printing Powder) |

Fine material

(plastic, metal, or ceramic) used in SLS, SLM, Binder Jetting, etc. |

|

Thermoplastic |

A type of

plastic that becomes pliable when heated and solidifies upon cooling;

commonly used in FDM. |

|

Engineering Materials |

High-performance

filaments or powders with specific mechanical properties (e.g., Nylon, PETG,

TPU, PC). |

|

Functional Material |

Material chosen

for its specific physical properties such as strength, flexibility, heat

resistance, or biocompatibility. |

|

Biocompatible Material |

Material safe

for contact with the human body, used in medical prototyping (e.g., certain

resins or titanium). |

4. Design & Pre-Processing Terms

|

Term |

Definition |

|

CAD (Computer-Aided Design) |

Software used to

create precise 3D models (e.g., SolidWorks, Fusion 360, AutoCAD). |

|

STL File (Stereolithography File) |

The standard

file format for 3D printing, representing the surface geometry of a 3D model

using triangles. |

|

OBJ File |

A 3D model file

format that includes both geometry and texture information; sometimes used in

3D printing. |

|

Slicing Software |

Software that

converts a 3D model into G-code instructions for the 3D printer by slicing it

into layers (e.g., Cura, PrusaSlicer, Simplify3D). |

|

G-code |

The machine

language that 3D printers read to execute the print job; generated by slicing

software. |

|

Wall Thickness |

The minimum

thickness of the outer surfaces of a 3D model; too thin may cause structural

failure. |

|

Clearance |

The intentional

space between moving or assembled parts to ensure they function correctly. |

|

Tolerance |

The allowable

limit of variation in a physical dimension; critical for functional parts. |

5. Post-Processing & Finishing Terms

|

Term |

Definition |

|

Post-Processing |

Any treatment

applied to a 3D printed part after printing to improve appearance, strength,

or functionality. |

|

Support Removal |

The process of

taking off support structures after printing. |

|

Sanding |

Smoothing the

surface of a print, often in preparation for painting or finishing. |

|

Priming & Painting |

Applying primer

and paint to improve aesthetics or simulate final product appearance. |

|

Polishing |

Smoothing and

shining the surface, often used with resin prints. |

|

Curing |

Hardening a

resin or printed part using UV light (common in SLA/DLP). |

|

Heat Treatment |

Applying heat to

improve mechanical properties, especially in metal or nylon prints. |

|

Surface Finish |

The texture,

smoothness, or visual quality of the printed part’s exterior. |

6. Quality & Performance Terms

|

Term |

Definition |

|

Resolution |

The level of

detail a 3D printer can achieve, often defined by layer height and X/Y axis

precision. |

|

Accuracy |

How closely the

printed part matches the intended dimensions of the 3D model. |

|

Tolerancing |

The expected

variation in size that is acceptable for the part to function correctly. |

|

Warping |

A common FDM

issue where the part distorts due to uneven cooling or temperature changes. |

|

Anisotropy |

The property of

a 3D printed part having different mechanical strengths depending on the

direction of the layers. |

|

Porosity |

Small voids or

gaps within a printed part, often in metal or SLS prints, which can affect

strength. |

|

Dimensional Accuracy |

The closeness of

a manufactured part’s dimensions to those intended in the design. |

7. Industry & Application Terms

|

Term |

Definition |

|

Functional Prototype |

A prototype that

is designed to be tested for real-world use, including mechanical or thermal

performance. |

|

Visual Prototype |

A prototype

created mainly for appearance, form, and aesthetics, not necessarily for

function. |

|

Proof of Concept (PoC) |

A prototype used

to demonstrate the feasibility of an idea or design. |

|

Low-Volume Production |

Manufacturing a

small number of units, often using 3D printing for cost-effective

customization. |

|

On-Demand Manufacturing |

Producing parts

only when needed, often enabled by digital 3D printing workflows. |

|

Digital Inventory |

Storing product

designs digitally and manufacturing parts via 3D printing as needed, reducing

warehousing. |

Bonus: Commonly Used Verbs & Actions in

3D Printing Workflows

|

Action |

Description |

|

Slice |

To divide a 3D

model into layers for printing using slicing software. |

|

Print / Print Job |

The act of

producing a physical object using a 3D printer. |

|

Generate G-code |

Creating machine

instructions from a 3D model for the 3D printer. |

|

Calibrate |

Adjusting the

printer settings or bed to ensure accurate prints. |

|

Adhere |

Ensuring the

first layer of the print sticks well to the print bed. |

|

Post-Cure |

Additional

curing process (often with UV light) to fully harden resin parts. |

Summary

Understanding

these professional 3D printing prototyping terms will help

you: