At the beginning of the development of industrial injection molding, how to keep the mold surface constant temperature has been puzzling people. In injection molding, the cooling time of finished products accounts for 70% of the injection molding production cycle. The main reason is that in traditional mold manufacturing, temperature control or cooling water path can only be drilled on a straight line. Critical hot spots are usually not within the range of cooling heat transmission, so they cannot be cooled effectively.

In order to keep the temperature constant, manufacturers have used diaphragms, radiators, cooling tubes, etc; We also try to laminate the blocks together, and add a drilling device with complex structure on the mold. How to complete manufacturing quickly and at low cost has become another big problem.

In 1997, Professor Sachs of Massachusetts Institute of technology first proposed the concept of "injection mold shape following cooling technology", and designing a cooling channel consistent with the contour of components is considered to be the best solution to control the injection molding temperature. However, conformal cooling increases the design difficulty and manufacturing complexity of mold manufacturing, which makes most traditional manufacturers shy away from it.

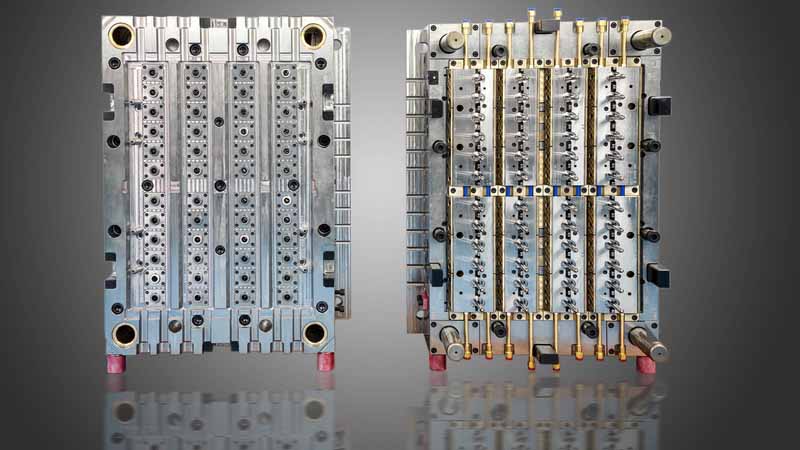

As a representative manufacturing technology of intelligent manufacturing, 3D printing technology has been widely used in China's manufacturing industry in recent years. Using direct metal laser sintering (DMLS) technology, the optimized conformal cooling water path can be integrated into the mold in the production process. Ensuring faster and more uniform heat dissipation can reduce the thermal stress in the mold and prolong the service life of the mold. The quality of plastic products and the dimensional accuracy of parts have also been improved, while reducing warpage deformation. In addition, the advantages of 3D printing technology in forming complex structures get rid of the forming limitations of traditional machining, and make the conformal cooling channel (conformal channel) of complex structures from design to reality. This process can also greatly shorten the production cycle of injection mold.