Mastars provides precision CNC processing, rapid prototyping, mass production, and has foreign advanced mold processing equipment, including product design (including appearance design and structure design), mold processing, injection molding, surface treatment, etc.

In order to save energy consumption, protect the environment and reduce CO2 emissions, the automobile industry must change the power drive source and corresponding various institutions, and reduce its own quality, so it needs to carry out technological innovation and transformation in many aspects.

At present, the power drive source has begun to change from fuel combustion engine to hybrid drive, pure electric drive and hydrogen fuel cell drive. Among them, pure electric vehicles save the most energy, and have simple structure, fast acceleration, low price and low noise.

However, there are also many shortcomings, such as short cruising distance, inconvenient and long charging time, and easy to be affected by external conditions; gasoline-electric hybrid energy vehicles still need internal combustion engines, so there are gearboxes, rotating systems, fuel tanks and oil circuits, etc. , After timely charging, it can be driven by electric drive, and the mileage is farther than that of pure electric vehicles.

So far, gasoline-fueled combustion engines and hybrid, electric and other types of vehicles co-exist, but industry insiders estimate that sooner or later, vehicles powered entirely by electricity will make up the majority of vehicles on the road.

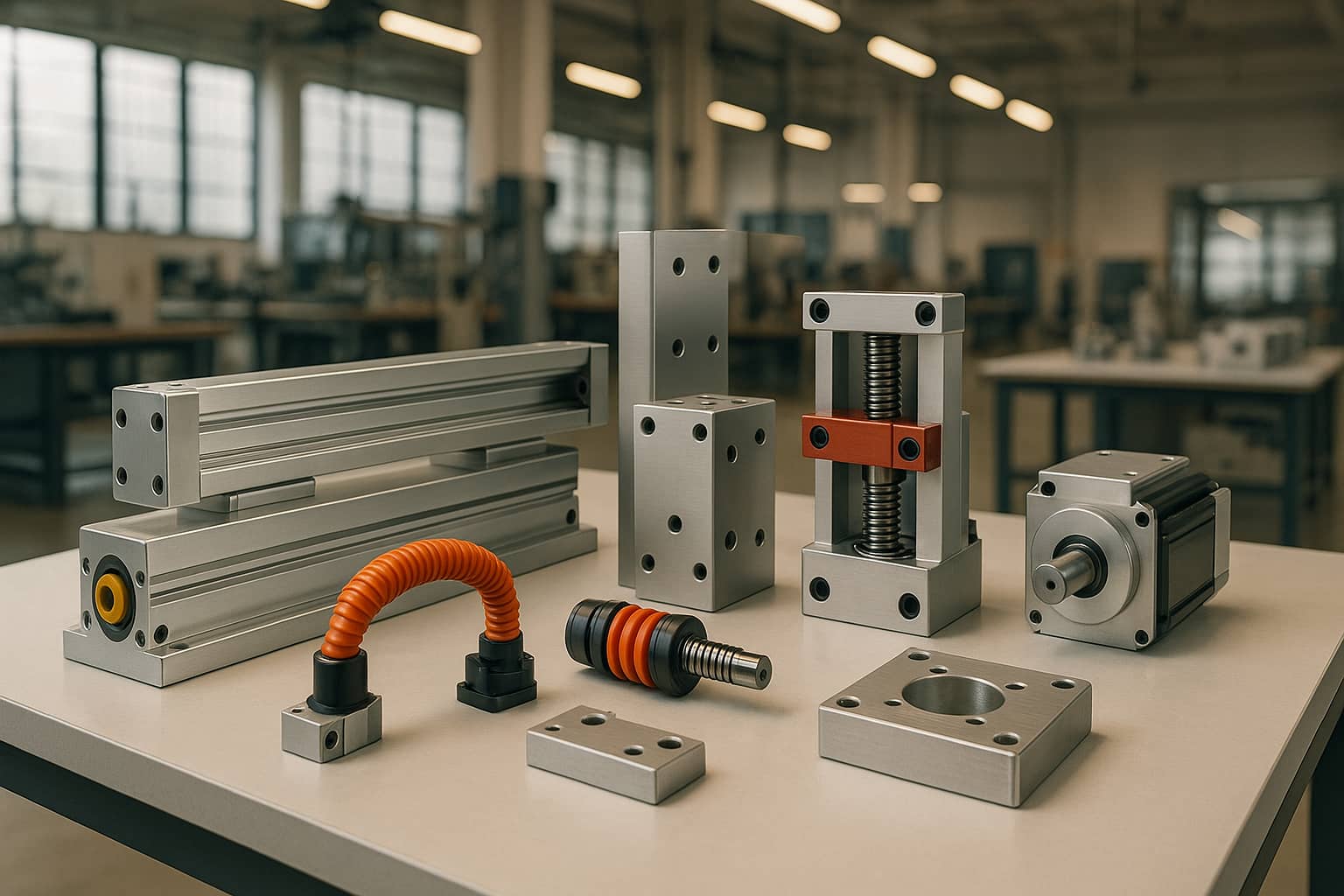

Many parts used in new energy vehicles are different from the original main parts of internal combustion engines, and the processing process and tools used are also different.

Taking the German MAPAL Group as an example, as a large enterprise supplying cutting tools to the automobile industry, they have considered this problem earlier, and gradually transferred the advanced technical experience accumulated in processing traditional power systems in the past decades to new energy vehicles. Parts are being processed.

In addition, as far as new energy vehicles are concerned, in order to improve and perfect themselves, many companies in many countries are constantly developing new system components, improving and launching new components and using new materials. In order to cope with these new parts and efficient processing of new materials, manufacturing companies should also make timely preparations.