1 Introduction to Aluminum Die Casting

Aluminum die casting represents one of the most efficient and versatile

metal-forming processes in modern manufacturing, combining the lightweight

advantages of aluminum with the precision of high-pressure molding techniques.

This process involves forcing molten aluminum alloy under high pressure into

reusable steel molds, known as dies, to produce complex, high-strength

components with exceptional dimensional accuracy. As industries increasingly

prioritize lightweighting for improved fuel efficiency and performance,

aluminum die casting has emerged as the manufacturing method of choice for

automotive, aerospace, electronics, and consumer goods applications.

The fundamental appeal of aluminum die casting lies in its unique

combination of properties: aluminum's innate lightweight characteristics (approximately

one-third the density of steel), excellent corrosion resistance, high thermal

and electrical conductivity, and impressive strength-to-weight ratio. When

processed through high-pressure die casting, these inherent material advantages

are enhanced by the manufacturing process's ability to produce near-net-shape

components with thin walls, complex geometries, and minimal secondary machining

requirements.

Global market trends underscore the growing importance of aluminum die

casting, particularly as industries transition toward more sustainable

manufacturing practices. The worldwide aluminum alloy high-pressure die casting

market has experienced significant transformation, driven by technological

advancements and evolving consumer demands. With the Asia-Pacific region

leading market growth due to rapid industrialization and a booming automotive

sector, aluminum die casting continues to evolve to meet increasingly stringent

performance and sustainability requirements.

This comprehensive article explores the aluminum die casting process in

detail, examining its technical fundamentals, material considerations, process

variations, applications across industries, and emerging trends that are

shaping the future of this vital manufacturing technology.

2 The Die Casting Process Explained

2.1 Mold Preparation and Design

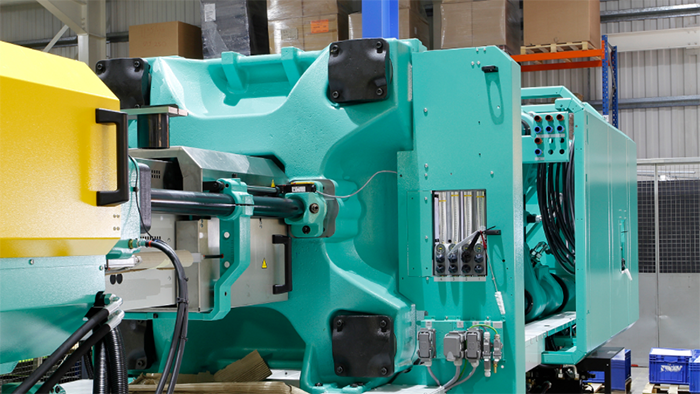

The aluminum die casting process begins with meticulous mold preparation,

where the reusable steel dies are designed and manufactured to exacting

specifications. These dies, typically constructed from heat-resistant steel

alloys such as H13, are hardened to 46-50 HRC and heat-treated for thermal

fatigue resistance. Properly maintained dies can last between 50,000 to 500,000

cycles, depending on the complexity of the part and the alloy being cast.

Critical to successful die design are several key features that ensure

optimal metal flow and part quality. Gating systems control the flow

of molten aluminum into the die cavity, with channels typically 3-8 mm wide

that regulate metal flow speeds of 1-5 m/s to avoid turbulence and air

entrapment. Venting systems consist of micro-channels (0.1-0.3 mm wide) that allow

trapped air and gases to escape, reducing defects like porosity and blistering. Cooling channels circulate water or oil at rates of 10-20 liters per

minute to maintain die temperatures between 200-300°C, ensuring uniform

solidification and reducing cycle times.

Modern die casting operations increasingly rely on simulation software

such as MAGMAsoft, Flow-3D, or ProCAST to optimize die design before

manufacturing. These powerful tools predict metal flow patterns, thermal

gradients, and potential defect areas, allowing engineers to make necessary

adjustments to gate placement, vent positioning, and cooling channel

configuration. Studies indicate that comprehensive simulation can reduce

casting defects by up to 30% before production begins, significantly improving

first-pass yield rates.

2.2 Injection and Solidification

Once the die is prepared and mounted in the die casting machine, the

aluminum alloy is melted in a separate furnace, typically at temperatures

between 660-720°C (1220-1330°F) for common alloys like A380, A360, or ADC12. Degassing is a critical

step at this stage, where rotating impellers inject argon or nitrogen into the molten

aluminum to remove dissolved hydrogen, which would otherwise cause porosity in

the final casting. Proper degassing can reduce porosity by up to 90%,

significantly enhancing the mechanical properties of the finished component.

The injection process varies depending on whether a cold chamber or hot

chamber machine is used. For aluminum alloys with their relatively high melting

points (~660°C), cold chamber machines are exclusively employed. In this

process, molten aluminum is ladled—manually or robotically—into a shot sleeve,

where a hydraulic plunger then forces the metal into the die cavity at high

pressures typically ranging from 10-175 MPa (1,500-25,000 psi). This injection

occurs in two distinct stages: an initial slow-fill phase that reduces turbulence

(approximately 0.01-0.1 seconds), followed by a rapid shot that completely

fills the cavity before solidification begins.

The injection parameters must be precisely controlled to avoid common

defects. Excessive turbulence can lead to oxide formation, while insufficient

pressure may result in incomplete filling, particularly for thin-walled

sections. Modern die casting machines employ sophisticated shot control systems

that monitor and adjust these parameters in real-time, ensuring consistent fill

conditions throughout production runs.

2.3 Ejection and Post-Processing

Upon complete filling of the die cavity, the molten aluminum begins almost

immediate solidification due to the thermal differential between the metal

(660+°C) and the die (typically 180-250°C). The high-pressure condition is

maintained during this phase—a critical step known as

"intensification"—which compensates for solidification shrinkage and

ensures dimensional stability. The rapid cooling rates of 500-1000°C per second

result in a fine-grained microstructure with superior mechanical properties

compared to slower casting methods. Components produced through high-pressure

die casting can exhibit strength improvements of 20-30% over conventional sand

casting techniques.

Once solidified, the die opens and ejection pins remove the casting from

the mold. Cycle times typically range from 30 seconds to 2 minutes, depending

on part thickness and size. After ejection, the components undergo various

post-processing operations. Trimming removes excess

material (flash, gates, and overflows) using hydraulic presses or CNC trimming

machines. Heat treatment may be applied to enhance mechanical properties, with T5

(artificial aging) and T6 (solution heat treatment plus aging) being common

treatments for aluminum die castings.

Table: Typical Aluminum Die Casting Cycle Times Based on Part

Characteristics

|

Part Size |

Wall Thickness |

Alloy Type |

Typical Cycle Time |

|

Small (<100g) |

Thin (<1.5mm) |

A380, ADC12 |

30-45 seconds |

|

Medium (100-500g) |

Medium (1.5-3mm) |

A360, A413 |

45-90 seconds |

|

Large (>500g) |

Thick (>3mm) |

A390, Al-Mg |

90-120 seconds |

For applications requiring precise dimensional tolerances or specialized

features, secondary machining operations are

performed. CNC machining centers create critical holes, threads, and sealing

surfaces with tolerances as tight as ±0.1 mm. Additional surface finishing

treatments—including deburring, vibratory tumbling, shot blasting, or

polishing—prepare components for their final applications. For enhanced

corrosion resistance or aesthetic appeal, surface treatments such as anodizing are employed,

which create a hard, protective oxide layer that can be dyed in various colors.

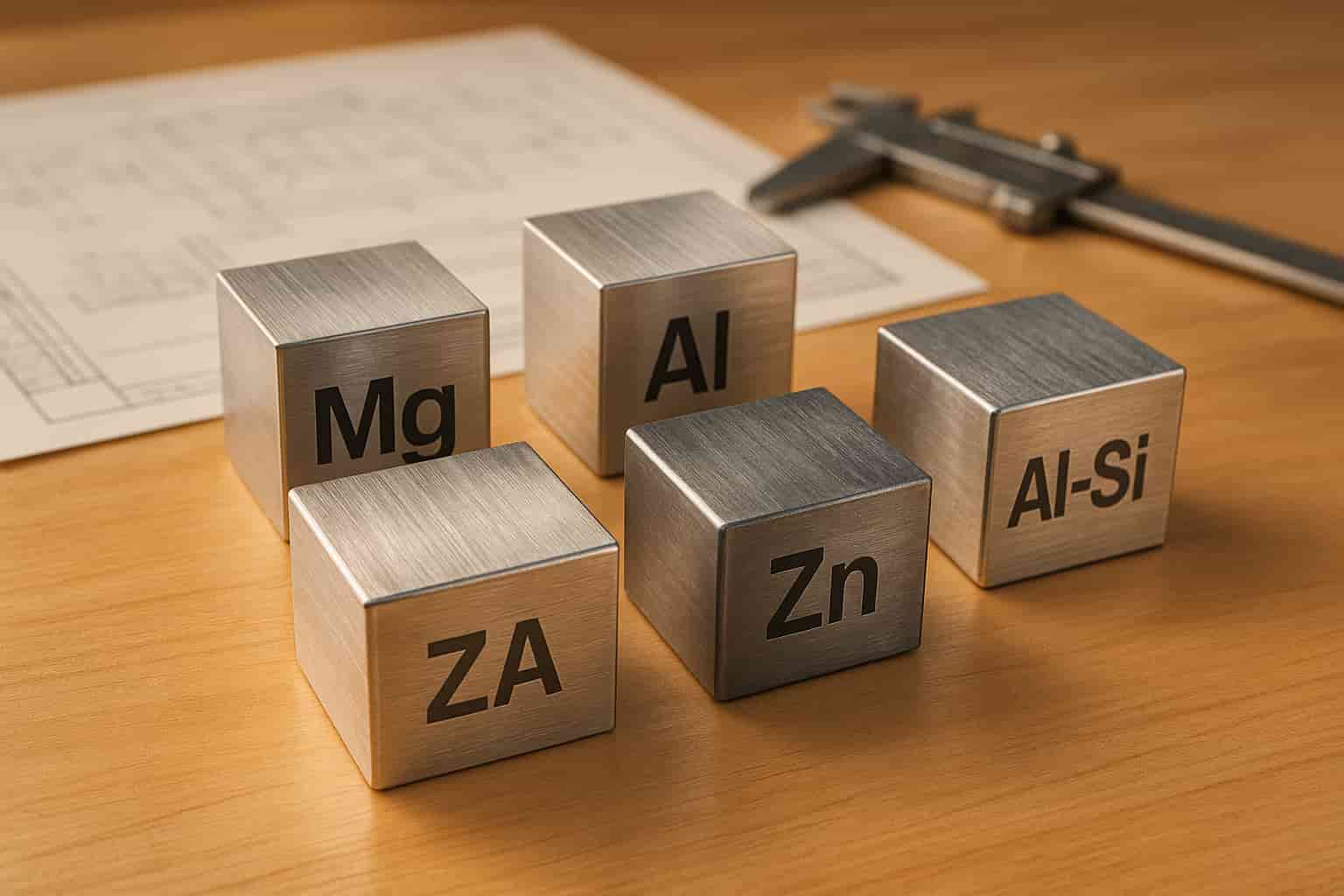

3 Key Aluminum Alloys and Material Selection

3.1 Common Alloy Systems and Their Properties

The selection of an appropriate aluminum alloy is critical to the success

of any die casting project, with each alloy offering distinct advantages for

specific applications. Aluminum alloys for die casting are primarily

categorized by their principal alloying elements, with silicon (Si), copper

(Cu), and magnesium (Mg) being the most commercially significant.

Al-Si (Aluminum-Silicon) alloys represent the

most widely used system for die casting, with silicon content typically ranging

from 5% to 12%. Silicon improves the fluidity of the molten aluminum, reduces

the melting point, and minimizes shrinkage during solidification. The most

prominent alloys in this category include:

Al-Mg (Aluminum-Magnesium) alloys provide excellent

corrosion resistance and good machinability, though they can be more

challenging to cast due to their tendency to oxidize and solder to die

surfaces. These alloys are particularly valuable for marine applications and

components exposed to corrosive environments.

Table: Properties of Common Aluminum Die Casting Alloys

|

Alloy |

Tensile Strength (MPa) |

Yield Strength (MPa) |

Elongation (%) |

Applications |

|

A380 |

320 |

160 |

3.5 |

Engine brackets, power tools, electronic enclosures |

|

ADC12 |

310 |

150 |

3.0 |

Automotive parts, consumer electronics |

|

A360 |

320 |

170 |

3.5 |

Marine components, battery housings |

|

A413 |

310 |

150 |

3.5 |

Thin-walled electronics, heat sinks |

3.2 Alloy Selection Considerations

Selecting the optimal aluminum alloy for a specific application requires

careful consideration of multiple factors, including mechanical requirements,

production considerations, and end-use conditions. Mechanical properties such as tensile

strength, yield strength, elongation, and hardness must align with the

component's functional requirements. For structural applications subjected to

high loads, alloys with higher copper content (like A380) may be preferable,

while components requiring impact resistance might benefit from alloys with

higher elongation characteristics.

Corrosion resistance is another critical consideration, particularly for

automotive, marine, and outdoor applications. Alloys with lower copper content

(such as A360) generally offer superior corrosion resistance, while

copper-bearing alloys provide higher strength but potentially reduced corrosion

resistance. The production process itself also influences alloy selection;

alloys with higher silicon content exhibit better fluidity, enabling the

production of thinner walls and more complex geometries.

Post-casting operations represent a third crucial consideration.

Components requiring extensive machining benefit from alloys with good

machinability characteristics, while those destined for anodizing or other

surface treatments may require specific alloy compositions to ensure optimal

results. It's worth noting that conventional die cast aluminum components can

be challenging to anodize due to the presence of surface porosity, which may

require specialized vacuum die casting techniques for applications requiring

anodized finishes.

4 Die Casting Methods: High-Pressure vs. Low-Pressure

4.1 High-Pressure Die Casting (HPDC)

High-pressure die casting (HPDC) is the most

common method for aluminum components, characterized by its rapid production

cycles and ability to produce complex geometries with thin walls. In this

process, molten aluminum is injected into the die under pressures typically

ranging from 10-175 MPa (1,500-25,000 psi). The high injection velocity ensures

complete filling of the die cavity before solidification begins, making it

ideal for parts with intricate details and tight tolerances.

The advantages of HPDC include high production rates (cycles lasting

seconds to minutes), excellent dimensional accuracy, and smooth surface

finishes that often eliminate the need for extensive secondary machining.

However, the rapid injection can sometimes lead to air entrapment, resulting in

porosity that may affect the mechanical properties of the casting. To address

this limitation, high-vacuum die casting (HVDC) has been

developed, which removes air from the die cavity before injection,

significantly reducing porosity and enabling the production of components

suitable for heat treatment and welding.

HPDC is particularly suitable for high-volume production runs where the

initial tooling costs can be amortized over a large number of parts. Typical

applications include automotive components, electronic enclosures, and consumer

goods where thin walls and complex geometries are required.

4.2 Low-Pressure Die Casting (LPDC)

Low-pressure die casting (LPDC) uses

significantly lower pressures, typically in the range of 0.1-0.7 MPa, to fill

the die cavity. In this process, the die is positioned above a sealed furnace

containing molten aluminum. Pressurized gas (usually air or inert gas) forces

the molten metal up through a riser tube and into the die cavity. The pressure

is maintained until the casting solidifies, after which the pressure is

released and the remaining molten metal returns to the furnace.

The primary advantages of LPDC include reduced turbulence during filling

(minimizing oxide formation and gas entrapment), higher yield due to the

absence of runners and biscuits, and improved mechanical properties resulting

from directional solidification. The process is particularly well-suited for

components with relatively uniform wall thickness and simpler geometries

compared to HPDC, such as wheels, structural components, and housings.

The main limitations of LPDC include slower cycle times compared to HPDC

and limitations on part complexity. However, for applications where mechanical

properties and structural integrity are prioritized over production speed, LPDC

offers significant advantages. The automotive industry frequently utilizes LPDC

for safety-critical components where high integrity and consistency are

required.

5 Design Considerations for Die Cast Components

5.1 Geometric Design Principles

Successful die casting components begin with design principles that

acknowledge both the capabilities and limitations of the process. Wall

thickness represents one of the most critical design

considerations. While aluminum die casting can produce walls as thin as 0.5 mm,

uniform wall thickness between 1.5-4.0 mm generally provides the optimal

balance of weight reduction, structural integrity, and manufacturability.

Significant variations in wall thickness should be avoided, as they create

differential cooling rates that lead to warpage, sink marks, and residual

stresses.

Draft angles facilitate part ejection from the die, with typical

values ranging from 1-3° per side depending on the depth of the feature and the

alloy being cast. External surfaces generally require less draft (1-2°) than

internal features (2-3°), with textured surfaces requiring additional draft

(approximately 1° per 0.025 mm of texture depth).

Ribs and gussets provide structural reinforcement without adding

significant mass, allowing for thinner wall sections while maintaining

stiffness. As a general guideline, ribs should be approximately 60-80% of the

nominal wall thickness to avoid sink marks on opposite surfaces. Similarly, fillet

radii should be incorporated at all intersections to reduce

stress concentrations and improve metal flow. Typical fillet radii range from

0.5-1.5 mm, with larger radii preferred for high-stress areas.

5.2 Feature Design and Optimization

Specific component features require particular design approaches to ensure

manufacturability and performance. Bosses designed to

accept fasteners should have a height no greater than twice their diameter,

with reinforcement gussets added for heights exceeding this ratio. Holes can be cast

directly into components, with practical minimum diameters around 1.5 mm and

depth-to-diameter ratios not exceeding 4:1 for through-holes or 2:1 for blind

holes. Deeper holes typically require secondary drilling operations.

Lettering and logos can be incorporated as raised or recessed features, with

recommended heights/depths of at least 0.25-0.5 mm for legibility. Parting

line placement significantly affects both tooling cost and

part quality, with ideal placements along a single flat plane whenever

possible. More complex parting lines increase die cost and maintenance

requirements but may be necessary for components with complex geometries.

Modern design for manufacturability (DFM) practices increasingly leverage

simulation software to optimize component designs before tooling manufacture.

Flow simulation predicts metal flow patterns, identifies potential air

entrapment areas, and optimizes gate and runner design. Thermal analysis

predicts solidification patterns, enabling designers to modify geometry to

minimize shrinkage porosity. These virtual prototyping tools have significantly

reduced the traditional trial-and-error approach to die casting design,

shortening development times while improving first-pass success rates.

6 Quality Control and Testing Methods

6.1 Non-Destructive Testing Techniques

Comprehensive quality assurance begins with non-destructive testing (NDT)

methods that evaluate component integrity without damaging the parts. X-ray

inspection represents one of the most valuable NDT techniques for

die castings, revealing internal defects such as porosity, shrinkage, and

inclusions. Modern digital X-ray systems can detect voids as small as 0.2 mm,

with automated defect recognition software classifying components based on

predefined quality criteria. This technique is particularly valuable for

safety-critical components in automotive and aerospace applications.

Dimensional verification ensures that components meet specified tolerances, with

coordinate measuring machines (CMM) providing accurate measurements of critical

features. Modern CMMs equipped with laser scanning capabilities can capture

complete surface geometries for comparison with CAD models, with accuracies

reaching ±0.025 mm. For high-volume production, specialized fixture-based

gauges provide rapid go/no-go verification of key dimensions.

Additional NDT methods include fluorescent penetrant testing for surface

defect detection, leak testing for components

requiring pressure tightness, and ultrasonic testing for wall

thickness verification. The specific combination of NDT methods employed

depends on the component's application, with safety-critical parts typically

undergoing more extensive testing.

6.2 Mechanical Testing and Process Control

Destructive testing provides verification of mechanical properties, with

samples selected at regular intervals throughout production runs. Tensile

testing measures ultimate tensile strength, yield strength, and

elongation, while hardness testing (typically

Brinell or Rockwell) provides a quick indicator of material properties

consistency. Fatigue testing may be performed for components subjected to cyclic

loading, though this more specialized testing is typically reserved for

validation purposes rather than production monitoring.

Statistical process control (SPC) forms the foundation of modern quality

assurance, with key process parameters monitored and charted to detect trends

toward specification limits before non-conforming parts are produced. Critical

parameters include metal temperature, die temperature, injection speed and

pressure, and cycle time. Modern die casting cells incorporate extensive sensor

networks that feed data to centralized monitoring systems, with automated

alerts triggering when parameters deviate from established control limits.

Certification standards including ISO 9001, IATF 16949 (automotive), and

NADCAP (aerospace) provide frameworks for quality system implementation, with

regular audits ensuring ongoing compliance. Production Part Approval Process

(PPAP) documentation validates that production processes can consistently

manufacture components meeting all design requirements.

7 Applications Across Industries

7.1 Automotive Industry

The automotive industry represents the largest market for aluminum die

castings, driven by the ongoing need for weight reduction to improve fuel

efficiency and reduce emissions. The average modern vehicle contains

approximately 180 kg of aluminum components, with die castings accounting for a

significant portion of this total. Notable applications include engine

blocks, transmission housings, structural components, and brackets of all types. The

transition to electric vehicles has further accelerated aluminum die casting

adoption, with large structural components such as battery trays and motor

housings increasingly produced via vacuum die casting to ensure pressure

tightness.

The industry trend toward larger, more integrated components is

exemplified by Tesla's pioneering use of massive giga-castings for underbody

structures. By consolidating numerous individual components into single die

castings, manufacturers achieve significant weight savings, reduce assembly

time and cost, and improve structural integrity. This approach represents the

cutting edge of die casting technology, requiring enormous machines with

clamping forces exceeding 6000 tons.

7.2 Consumer Electronics

The consumer electronics industry values aluminum die castings for their

combination of structural integrity, heat dissipation capabilities, and premium

appearance. Laptop and smartphone housings benefit from

aluminum's rigidity and electromagnetic interference (EMI) shielding

properties, while heat sinks for gaming consoles and networking equipment leverage

aluminum's excellent thermal conductivity. The ability to produce thin-walled

components with complex geometries makes die casting particularly suitable for

electronic enclosures, with wall thicknesses as thin as 0.5 mm achievable in

production quantities.

Aesthetic considerations play a significant role in electronic

applications, with die cast components often receiving sophisticated surface

treatments including precision machining, anodizing, and painting. The high

thermal conductivity of aluminum alloys (approximately three times that of

steel) provides passive thermal management for increasingly powerful electronic

components, reducing or eliminating the need for active cooling systems in many

applications.

7.3 Aerospace and Industrial Applications

The aerospace industry employs aluminum die castings for non-critical

components where the excellent strength-to-weight ratio justifies the tooling

investment. Applications include brackets, housings, and structural

components for aircraft and satellites. The stringent quality

requirements for aerospace applications necessitate rigorous process controls

and extensive documentation, with certification to standards such as NADCAP

often required.

Industrial applications range from pump housings and valve

bodies to gear cases and hydraulic

manifolds. These components benefit from the pressure tightness, corrosion

resistance, and durability of die cast aluminum, with specific alloys selected

based on operational requirements. The excellent bearing properties of

high-silicon alloys make them particularly suitable for rotating component

applications, reducing wear and extending service life.

8 Future Trends and Innovations

8.1 Technological Advancements

The die casting industry continues to evolve through technological

innovations that improve quality, efficiency, and capabilities. Vacuum die

casting has emerged as a significant advancement for producing

high-integrity components with minimal porosity. By evacuating air from the die

cavity before injection, this process reduces gas entrapment, enabling the

production of components that can be heat treated and welded. The automotive

industry in particular has embraced vacuum die casting for structural safety

components.

Automation and Industry 4.0 technologies are

transforming die casting operations through enhanced monitoring and control

capabilities. Robotics handle repetitive tasks such as ladling, part extraction,

and trimming, improving consistency while reducing labor costs and safety

risks. IoT sensors monitor equipment health and process parameters in

real-time, with data analytics identifying optimization opportunities and

predicting maintenance needs before failures occur.

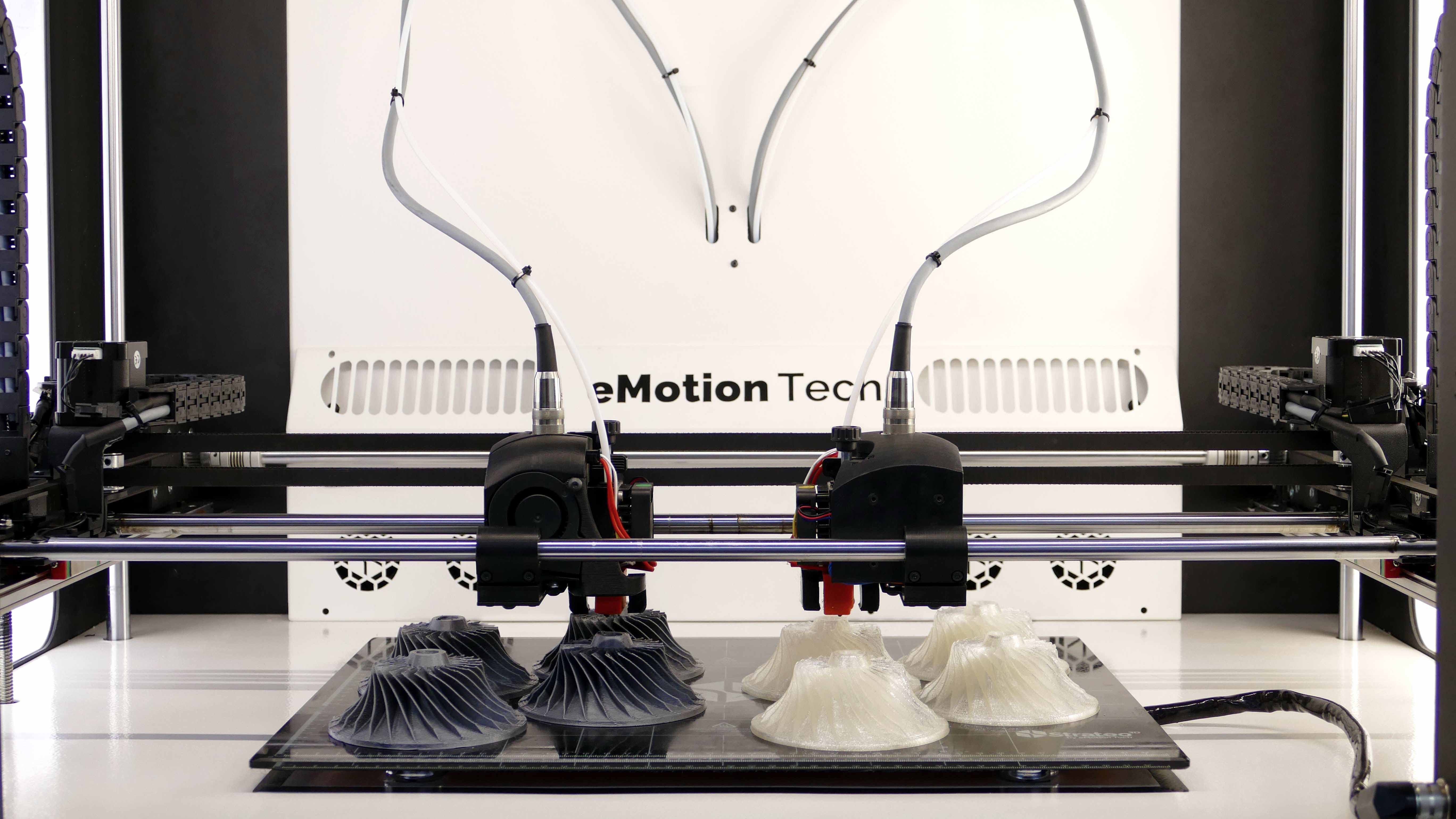

Additive manufacturing has found applications in die casting through 3D-printed

mold inserts with conformal cooling channels. These complex cooling

passages follow the contour of the die cavity, providing more uniform thermal

management that reduces cycle times while improving part quality. While

currently used primarily for prototyping or short production runs, as the

technology matures, additive manufacturing is expected to play an increasingly

important role in conventional die casting operations.

8.2 Sustainability Initiatives

Environmental considerations increasingly influence die casting

operations, with manufacturers implementing numerous sustainability

initiatives. Closed-loop recycling systems remelt

scrap generated during production (typically 5-10% of material input),

significantly reducing raw material requirements. The energy efficiency of

recycling aluminum—requiring only 5% of the energy needed for primary aluminum

production—makes this both environmentally and economically beneficial.

Energy consumption reduction efforts focus on

more efficient melting and holding technologies, with modern furnaces

incorporating improved insulation and combustion systems. Some facilities

employ waste heat recovery systems that capture and reuse thermal energy that

would otherwise be lost. Water-based lubricants have largely replaced

petroleum-based products, reducing volatile organic compound (VOC) emissions,

while closed-loop water systems minimize consumption through recycling and

reuse.

As sustainability becomes an increasingly important purchasing criterion,

manufacturers are pursuing certifications including ISO 14001 (environmental

management) and implementing carbon accounting systems. Some leading companies

have announced ambitions for carbon-neutral manufacturing, driving further

innovation in sustainable die casting practices.

9 Conclusion

Aluminum die casting continues to be a vital manufacturing process that

balances economic production with high-performance outcomes. Its unique combination

of design flexibility, material efficiency, and excellent mechanical properties

ensures its ongoing relevance across diverse industries. As technological

advancements address traditional limitations and sustainability considerations

become increasingly important, aluminum die casting is poised to maintain its

position as a manufacturing method of choice for the complex, high-performance

components required by modern industry.

The future of aluminum die casting will likely see greater integration

with digital technologies, expanded material options, and increasingly

sophisticated process controls that further enhance quality and efficiency. As

industries continue to prioritize lightweighting and sustainability, the

inherent advantages of aluminum die casting—coupled with ongoing process

innovations—ensure that this manufacturing technology will continue to evolve

and expand its applications in the years ahead