Forging parts are especially suitable for working in harsh and high-strength environment. Forging process, especially hot forging and warm forging, is widely used in various industries because of its higher strength and lighter quality. Forging has become an irreplaceable production process with its obvious advantages. If you just need this service, mastars can meet your requirements and exceed your expectations.

We have more than 20 years of forging experience, focusing on hot forging, warm forging, cold forging and 3D forging technology for non-ferrous metals such as copper forging, aluminum alloy

forging, stainless steel forging, etc.

● Mastars forging fabrication

● Mastars forging fabrication

More than 20 years of professional forging experience.

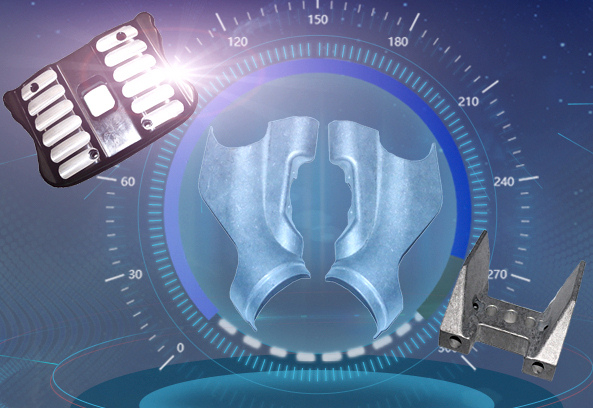

One-stop customized service of mold development, mold manufacturing, product manufacturing and surface treatment. Years of experience in motorcycle industry and examples of cooperative customers. > Hot forging > Warm forging > Cold forging ● Our hardware equipmentSupporting large-scale equipment: 4000 tons, 2500 tons, 800 tons, 630 tons, 400 tons forging machines, 1000 tons 4D forging machines, 500 tons 3D forging machines, CNC machining centers, punches, spark machines, electric discharge machines, grinders, etc. Forging equipment with a tonnage of 4000 tons can forge workpieces with an outer diameter of 500mm and a length of 1000mm. The forging precision can reach 0.1--0.2mm, and the machining dimensional accuracy tolerance is 0.01-0.05mm.

● Our hardware equipmentSupporting large-scale equipment: 4000 tons, 2500 tons, 800 tons, 630 tons, 400 tons forging machines, 1000 tons 4D forging machines, 500 tons 3D forging machines, CNC machining centers, punches, spark machines, electric discharge machines, grinders, etc. Forging equipment with a tonnage of 4000 tons can forge workpieces with an outer diameter of 500mm and a length of 1000mm. The forging precision can reach 0.1--0.2mm, and the machining dimensional accuracy tolerance is 0.01-0.05mm.

Based on years of experience in the industry and strong production capacity, we can easily meet the production needs of various forged parts.

If you just need this service, Mastars can meet your requirements and exceed your expectations.

Why are forged wheels so expensive?|forging|rapid cnc machining

Why are forged wheels so expensive?|forging|rapid cnc machining

Understand forging process|Mastars|forging manufacturer

Understand forging process|Mastars|forging manufacturer

Why are stainless steel forgings widely promoted?|mastars|rapid cnc machining

Why are stainless steel forgings widely promoted?|mastars|rapid cnc machining

What are the characteristics of stainless steel forging process?|prototype maker

What are the characteristics of stainless steel forging process?|prototype maker