-

-

BELKIN

-

-

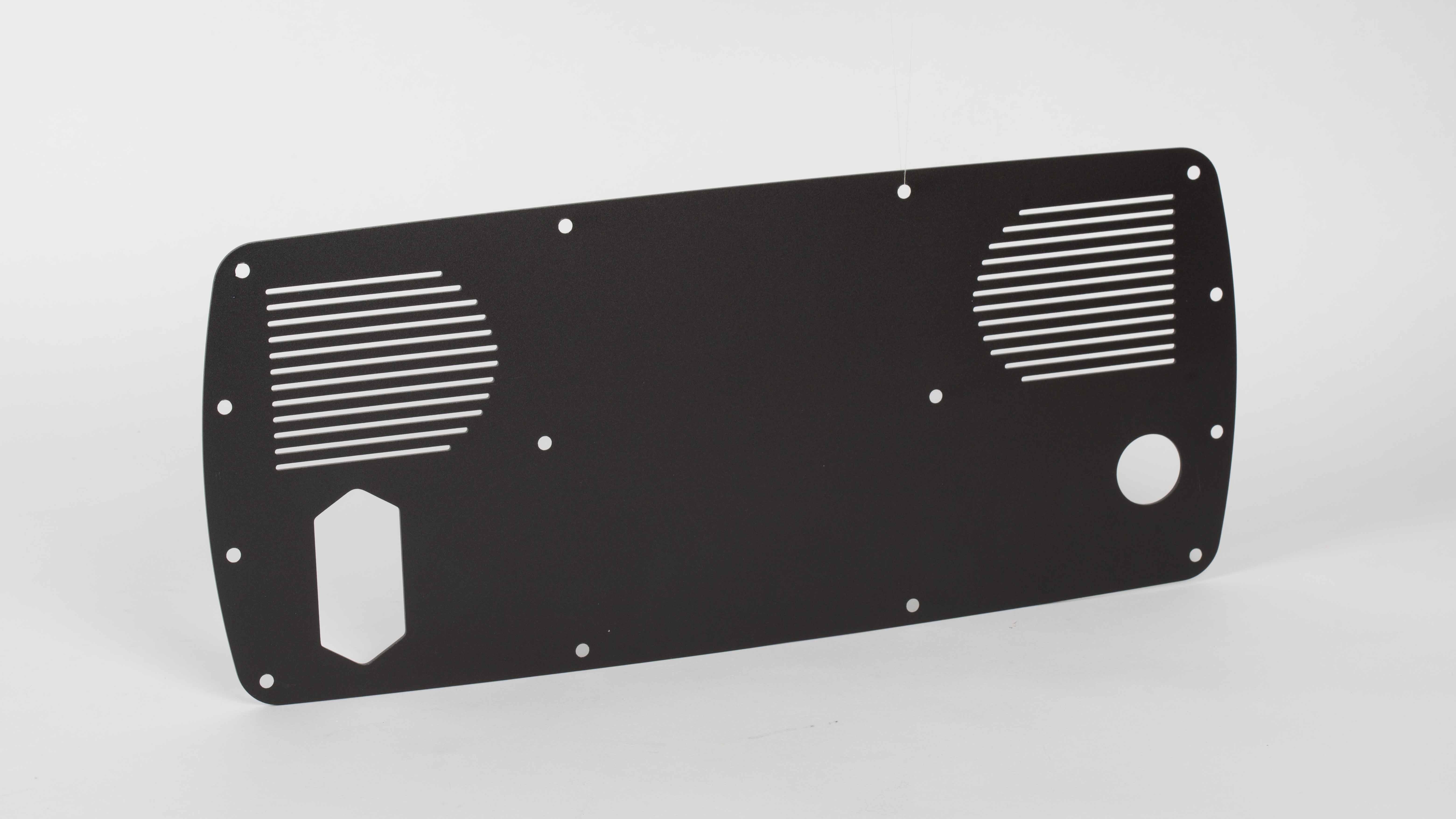

How to prevent corrosion after sheet metal processing?|metal prototype makerFor sheet metal products, most materials except stainless steel require anti-corrosion, anti-rust and anti-oxidation. Ma...

-

-

CPR & AED Training for Everyone’s SafetyTaking care of your heart is really important, so everyone should pay attention to their heart health.

-

-

Future of Sheet Metal Recycling in Automotive IndustrySheet metal recycling is reshaping the automotive industry. Why? It reduces waste, cuts costs, and supports energy-effic...

-

-

3D printing manufacturing artificial eye|3d printing services|mastarsAn artificial eye developed by a team in the United States uses 3D printing technology to distribute some special ink on...

-

-

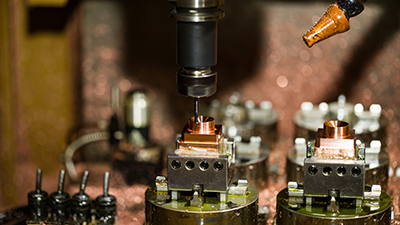

Everything You Need to Know About CNC MillingVarious types of processing can be performed on a CNC machine. They can be cut (milled), drilled, planed, sharpened, and...

-

-

Injection molding process of child safety seat|rapid prototyping servicesMastars manufactures high quality and precision products for the automotive, electronics, medical and outdoor industries...

-

-

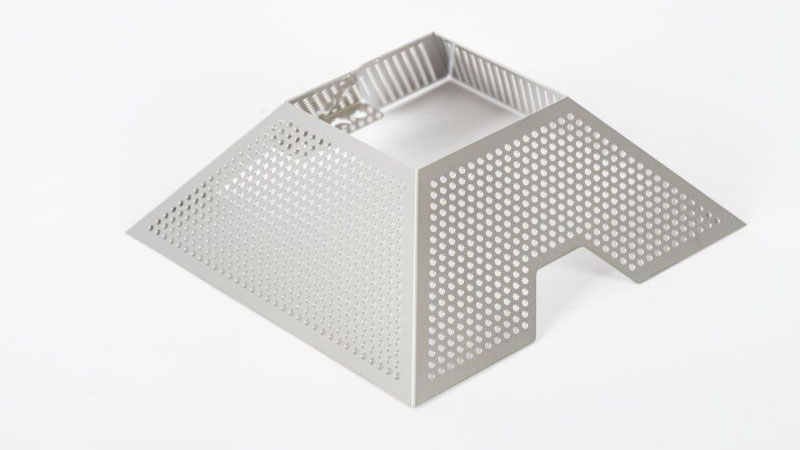

Manufacturing service cases in audio industryAs the world-leading brand in the professional audio industry, Solid State Logic always provides exceptional musical enj...

-

-

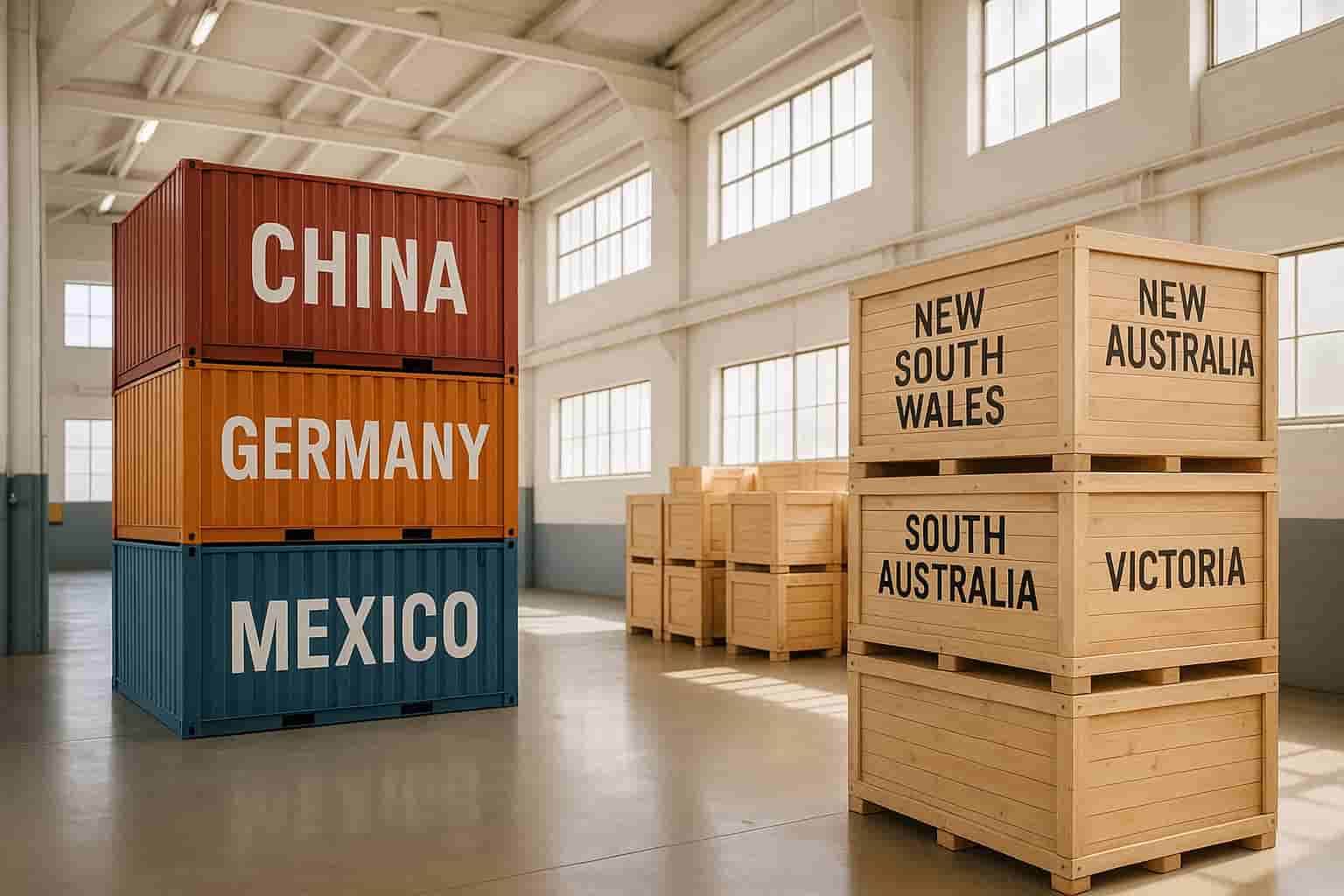

Regional vs. Global Material Sourcing: Cost ComparisonChoosing between regional and global sourcing involves more than just material costs. Regional offers speed and reliabil...

Contact us

- Building 6 , Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City,Guangdong, China (518104)

- marketing@mastars.com

Rapid Prototyping Tooling Terms Glossary

Here is a detailed

English-language guide to the professional terminology associated with Rapid Prototyping Tooling (often shortened to Rapid Tooling).

This glossary is

organized to follow the logical progression from concept to finished tool.

Rapid Tooling: Professional Terminology (English

Version)

Category 1: Core Concepts & Classifications

|

Term |

Definition & Context |

|

Rapid Tooling (RT) |

A broad set of techniques that use additive

manufacturing or other fast processes to create molds, dies, or patterns

quickly and cost-effectively for prototyping and low-volume production. |

|

Bridge Tooling |

Tooling that serves as a "bridge"

between prototyping and full-scale production. It is more robust than a

simple prototype mold but not as durable as production tooling. |

|

Soft Tooling |

A general term for molds made from less

durable materials, typically used for 50-1,000 parts. Common

materials include aluminum, soft steel, silicone

rubber, and epoxy

composites. |

|

Hard Tooling |

Refers to traditional, long-life production

molds made from hardened steel. These are

designed for high-volume production (millions of cycles) and involve high

cost and long lead times. |

|

Indirect Rapid Tooling |

A method where a master

pattern (usually 3D printed) is first created. This pattern is then used to

produce a secondary, negative mold (e.g., from silicone or epoxy), which is

used to cast the final parts. |

|

Direct Rapid Tooling |

A method where the tool itself (e.g., a

mold insert) is fabricated directly using an additive process, such as Direct

Metal Laser Sintering (DMLS). |

|

Mold Life / Number of Shots |

The estimated number of parts that can be

produced from a mold before it fails or its accuracy degrades. This is the

key trade-off in RT (e.g., a silicone mold may have a life of 25 shots, while

a soft aluminum mold may last for 10,000). |

Category 2: Master Pattern & Processes

|

Term |

Definition & Context |

|

Master Pattern |

A high-fidelity, dimensionally accurate

model of the final part, used in indirect methods to create the

mold. It is typically produced using Stereolithography (SLA) or Material

Jetting for high surface quality. |

|

Silicone Rubber Molding |

Another name for the Vacuum

Casting process. The mold is made from Room Temperature Vulcanizing (RTV)

silicone rubber. |

|

Vacuum Casting |

A primary indirect RT process. A vacuum is

used to draw liquid polyurethane resin into a silicone mold, ensuring the

resin fills intricate details and minimizing air bubbles. |

|

RTV Silicone |

Room Temperature Vulcanizing Silicone. The two-part

silicone rubber used to make flexible molds; it cures at moderate

temperatures. |

|

K-Factor (Shrinkage Factor) |

A multiplier applied to the CAD model of

the master pattern to compensate for the cumulative shrinkage of both the

mold material (silicone) and the cast material (polyurethane). |

Category 3: Direct Tooling Methods & Materials

|

Term |

Definition & Context |

|

Direct Metal Laser Sintering (DMLS) |

An additive manufacturing process that uses

a laser to sinter/fuse fine metal powder particles layer by layer to build a

fully dense metal part. Used to create metal mold inserts directly from

CAD data. |

|

Selective Laser Melting (SLM) |

Similar to DMLS, but the metal powder is

fully melted rather than sintered, resulting in parts with different

mechanical properties. |

|

Binder Jetting |

An additive process where a liquid binding

agent is selectively deposited to join powder particles (polymer, sand, or

metal). In RT, it's famously used for 3D printed sand molds for metal

casting. |

|

RapidSteel / LaserForm |

Historic tradenames for metal-polymer

composites or metal powders used in early direct metal RT processes. The

terms are sometimes still used generically. |

|

Epoxy Composite Tooling |

A method where a mold is made from an epoxy

resin filled with conductive materials like aluminum or copper powder to

improve strength and thermal performance. |

|

Sprayed Metal Tooling |

A process where a thin shell of metal

(e.g., zinc or aluminum) is thermally sprayed onto a master pattern. The

shell is then backed with a strong filler like epoxy or ceramic to create a

mold. |

|

Soft Aluminum Mold |

A mold machined from a block of aluminum

(e.g., 6061 or 7075). It is "soft" because it is not heat-treated.

It offers a good balance of speed, cost, and life for Bridge

Tooling. |

|

Kirksite |

A low-melting-point zinc alloy that can be

cast into a mold shape. It is easy to machine and repair but has a relatively

low melting point, limiting its use to lower-temperature processes. |

Category 4: Tooling Design & Features

|

Term |

Definition & Context |

|

Mold Insert |

A block, often containing the core or

cavity of the mold, that is inserted into a standard mold

base. RT is often used to create these inserts. |

|

Mold Base |

A standardized frame that holds the mold

inserts, ejection system, and cooling channels. Using a standard base saves

cost and time. |

|

Conformal Cooling Channels |

A major advantage of Direct

Metal RT. Cooling channels are 3D printed to conform to (follow) the shape of the

part cavity, leading to faster, more uniform cooling than straight drilled

channels. |

|

Draft Angle |

A slight taper applied to vertical faces of

a part to facilitate its ejection from the mold. Critical for all molding

processes. |

|

Parting Line |

The line or plane where the two halves of a

mold meet. |

|

Shrinkage Allowance |

The dimensional compensation factored into

the tool's design to account for the material shrinkage of the final part

material (e.g., polypropylene shrinks significantly) as it cools. |

Category 5: Applications & Validation

|

Term |

Definition & Context |

|

Functional Prototype |

A prototype made via RT that is used to

verify not just shape, but also fit, function, and performance under

conditions that simulate the final product. |

|

Low-Volume Production |

The manufacture of end-use parts in

quantities from 10s to 1,000s, for which traditional hard tooling is not

economical. This is the primary application of RT. |

|

Pilot Run |

A small-scale production run used to

validate the manufacturing process, train assembly staff, and produce parts

for market testing before full-scale production begins. |

|

Technology Readiness Level (TRL) |

A scale used to estimate the maturity of a

technology. RT helps raise the TRL by enabling the creation of parts from the

intended manufacturing process. |

|

Lifecycle (of a Tool) |

The stages a tool goes through, from design

and fabrication to production use and eventual decommissioning. RT tools have

a shorter but much faster lifecycle. |

This vocabulary provides a solid foundation

for discussing strategies for accelerating product development and

manufacturing introduction using Rapid Tooling technologies.

【Editor】:Mastarsall rights reserved:https://www.mastars.comPlease indicate the source