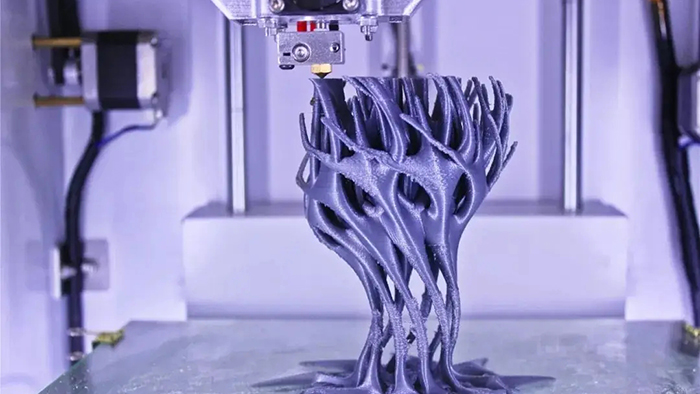

Mastars' rapid prototyping service can provide various prototyping services according to customers' needs, verify your designed, provide fast, efficient and cost-effective services, and lay the foundation for future mass production of your products.

Whether it's your car, your phone, your home, or any of your tools or appliances, these are all products of custom sheet metal fabrication.In this article, we're giving you a complete guide to everything you need to know about sheet metal fabrication, from its very definition to its creation and customization process, along with the role it plays in keeping everything in our lives operational.

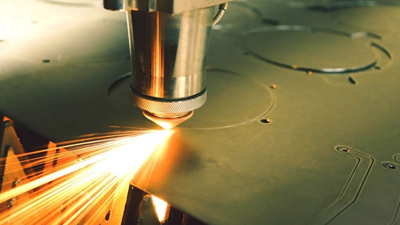

Sheet metal processing is a comprehensive cold working process for sheet metal (usually less than 6mm), including shearing, blanking, bending, welding, riveting, die forming and surface treatment. Its remarkable feature is that the thickness of the same part is the same.

Our common sheet metal processing mainly consists of six steps, which are introduced in detail below: sheet metal processing drawing design - laser processing or (NC stamping) - bending - welding forming - electrostatic powder spraying or (liquid paint) - packaging and shipping

1. Drawing design: general customers provide drawings or samples, which are measured, designed and developed by the company's engineers to form processing decomposition drawings and assembly drawings and submit them to the production department for processing.

2. The laser cutting machine has the advantages of smooth cutting of carbon steel workpiece, and the laser cutting machine can not replace the laser cutting of stainless steel workpiece. The cutting section is more beautiful.

3. CNC stamping: turret CNC punch is mainly used for products with thin material thickness, which is generally suitable for materials below 2.5mm. There are many holes in sheet metal processing workpieces or workpieces that need to be processed with special molds. When the batch is large, CNC stamping has a certain cost advantage.

4. Bending: if most of the workpieces need to be bent after blanking, the company has multiple computer bending machines, which is not only fast, but also more accurate.

5. Welding forming: the workpiece generally needs to be assembled and formed after blanking. There are many kinds of assembly methods. Some are directly formed by non welding processes such as screws and riveting. Generally, the sheet metal of mechanical shell is mostly formed by welding. The company generally adopts argon arc welding, touch welding, carbon dioxide welding, etc. after welding, the workpiece is polished and polished, so that the workpiece is relatively firm and beautiful.

6. Electrostatic powder spraying: electrostatic powder spraying is mainly aimed at carbon steel workpieces. In the process, it is generally carried out first, such as oil and rust removal, surface conditioning cleaning, phosphating treatment, electrostatic powder spraying, high-temperature baking and other processes. After treatment, the workpiece surface is beautiful, will not rust for several years, low cost and other advantages.

Liquid paint: this process is different from electrostatic powder spraying. Generally, it is aimed at large workpieces. When it is impossible to handle, the use of liquid paint has the advantages of convenience and low cost. Liquid paint is generally divided into two steps. After the workpieces are treated, apply primer and then apply paint.

7. Packaging and shipment: 100% inspection shall be conducted before packaging, and inspection data shall be provided. The shipping requirements and packaging methods shall be confirmed by the customer's representative on site. It is hereby recorded for the customer's reconfirmation

Mastars are principally engaged in the manufacture of plastic/metal parts business including automotive, industrial and moulds. As manufacturing expertise in China, we provide philosophy, customers benefit from our unique blend of philosophy, customers benefit from our unique blend of quality, reasonable cost, integrated services and flexibiliy.

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210690

Mobile: +86 181 0029 4997

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China