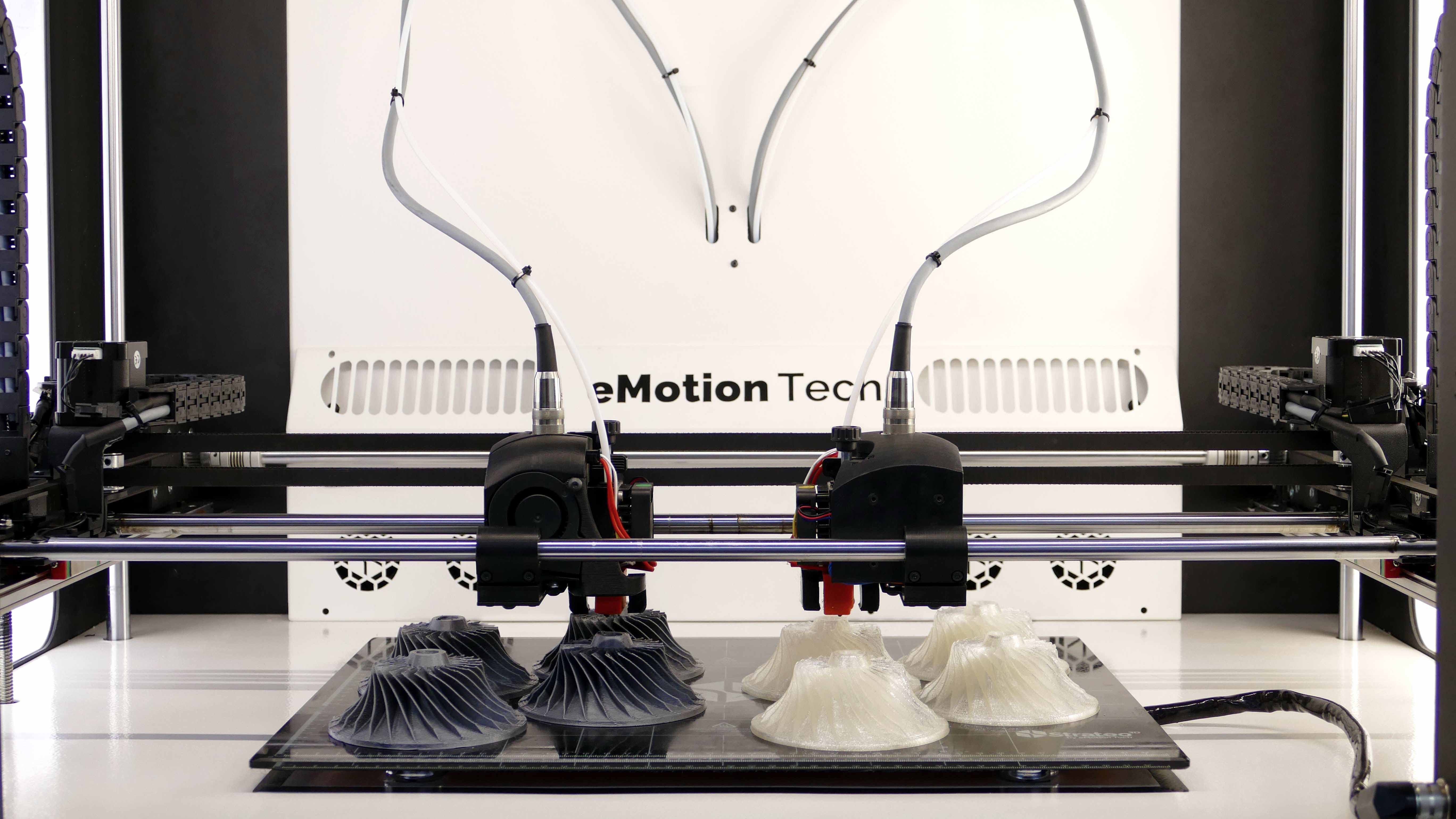

Selecting the right material is crucial for the success of any 3D printing project. This guide will help you understand the properties, applications, and availability of various 3D printing materials in Australia.

Before diving into material options, take a moment to clearly outline what your project demands. A detailed understanding of your requirements is the first step toward making informed decisions.

Once you've defined your project requirements, it's time to explore materials that align with your needs. Knowing the unique characteristics of each material helps you make an informed choice.

Great for beginners. This biodegradable thermoplastic prints at relatively low temperatures (190-220°C) and produces minimal odor. Not suitable for hot environments (glass transition ~60°C).

Tougher option with better durability and heat resistance (glass transition ~105°C). Ideal for functional parts like automotive components and electronic housings.

Standout for its strength, flexibility, and resistance to chemicals. Tensile strengths often exceed 70 MPa. Excellent for gears, bearings, and structural parts.

Unmatched surface quality and intricate details. Perfect for jewelry, dental models, and miniatures. Requires careful handling and post-processing.

Blends the ease of PLA with the toughness of ABS. Chemical-resistant and works well for food-safe applications, protective equipment, and transparent parts.

Exceptional impact resistance and ability to withstand continuous use at temperatures up to 140°C. Used in safety gear, automotive lighting, and electronic components.

Improves on ABS by offering better UV resistance and weather durability. Perfect for outdoor applications in intense sunlight.

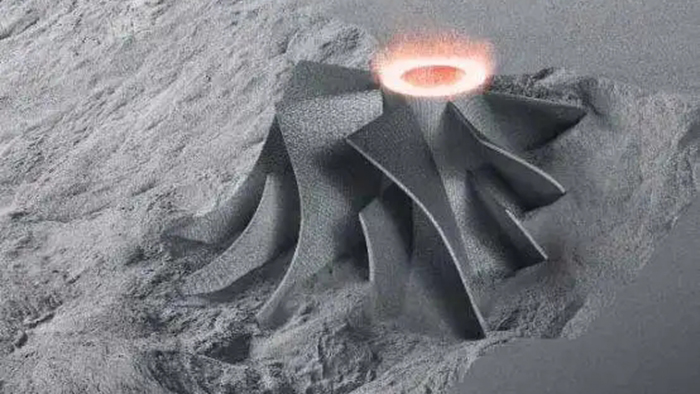

Combine base polymers with chopped carbon fibers, resulting in materials that are incredibly stiff and strong while remaining lightweight.

Once you've identified your project requirements, the next step is to compare how different materials perform.

| Material | Tensile Strength (MPa) | Heat Resistance (°C) | Ease of Printing | Cost Level | Best Applications |

|---|---|---|---|---|---|

| PLA | 37-50 | 60 | Excellent | Low | Prototypes, decorative items, educational models |

| ABS | 40-55 | 105 | Moderate | Low-Medium | Automotive parts, electronics housings, tools |

| PETG | 45-55 | 85 | Good | Medium | Food containers, protective equipment, transparent parts |

| Nylon | 70-85 | 120 | Challenging | Medium-High | Gears, bearings, automotive components |

| ASA | 42-55 | 105 | Moderate | Medium | Outdoor signage, automotive exterior, garden tools |

| Polycarbonate | 55-75 | 140 | Difficult | High | Safety equipment, optical components, high-temp applications |

| Standard Resin | 25-40 | 60 | Good | Medium | Miniatures, jewelry, dental models |

| Carbon Fiber Nylon | 90-130 | 120 | Challenging | High | Aerospace, drones, high-performance sporting goods |

Once you've evaluated performance and application needs, it's time to weigh up local pricing, availability, and environmental factors.

In Australia, material prices vary based on their properties and availability. PLA is the most budget-friendly option, while high-performance materials like nylon, polycarbonate, and carbon fiber composites come at a premium.

Australia's growing 3D printing industry now boasts a strong network of local suppliers. These distributors provide reliable access to a variety of materials, ensuring quicker delivery times and consistent quality.

Sustainability plays a significant role in Australia's 3D printing landscape. PLA is often praised for its eco-friendly profile, while ABS can be mechanically recycled. PETG integrates well with existing recycling systems.

Choosing the right 3D printing material involves matching your project's needs with the material's properties. It's all about finding the sweet spot between performance, cost, and practical factors.

Start by defining your project's core requirements. While budget is always a factor, it's important to look beyond the upfront costs. Availability also plays a big role, especially if you're working on a tight timeline.

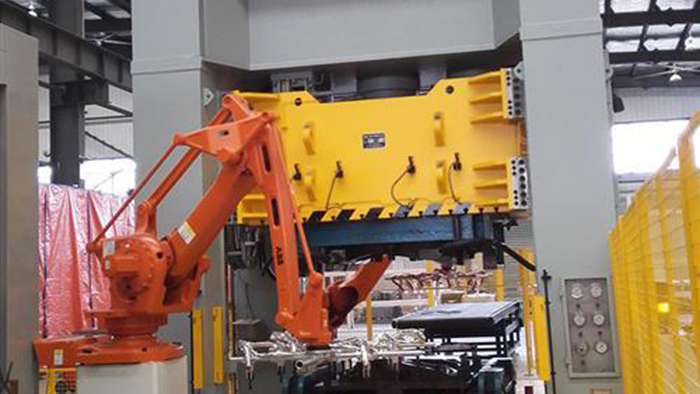

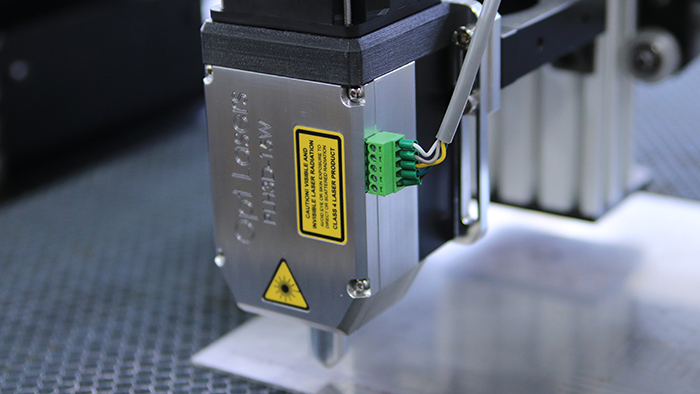

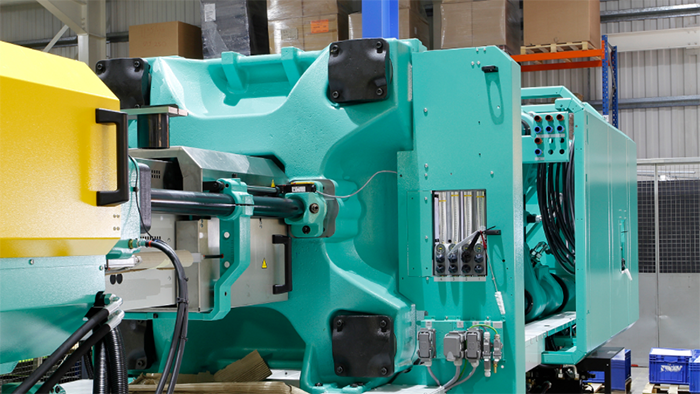

Tapping into local expertise can make a huge difference. Companies like Mastars bring a wealth of experience in industries such as automotive, medical, and electronics.

For projects that demand both heat resistance and biocompatibility, PEEK and ULTEM (PEI) are standout thermoplastics. These materials handle temperatures above 100°C with ease and are frequently used in medical applications.

Heat-resistant polyacrylate materials are another solid choice. They are designed to endure steam sterilization and repeated temperature changes, making them a reliable option for clinical environments.

When looking for 3D printing materials in Australia, it's important to weigh up factors like cost, availability, and project needs. Materials such as PLA or ABS filaments generally cost between AU$30 and AU$63 per kilogram.

Availability plays a big role too. Sourcing locally can cut down on shipping delays and lower freight costs. That said, fluctuating demand and stock levels can sometimes stretch lead times.

To make eco-friendly choices for 3D printing materials in Australia, consider using biodegradable options like PLA or materials crafted from recycled plastics. These alternatives help cut down reliance on virgin resources and reduce waste.

You can also choose materials that emit fewer harmful substances during printing and consume less energy in processing.