Detail Guide About Aluminum Injection Molding

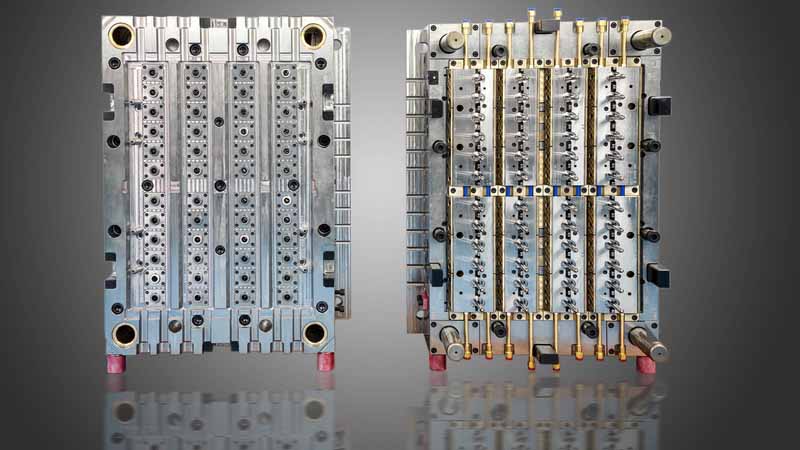

What Is Aluminum Injection Molding?

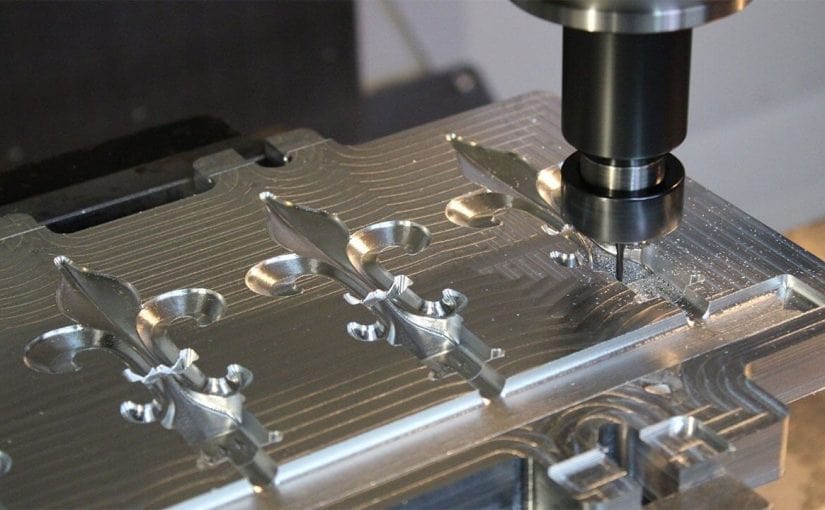

Prototypes or real products are produced by the aluminum injection molding technique. The aluminum tooling technique is used for the process of aluminum injection molding. It is the process based on the

injection molding technique.Aluminum and its alloys are used in various types of markets such as aerospace, automobiles, electronics, etc.

Mastars is also a metal prototype maker.

Benefits of Aluminum Injection Molding

• *Regarding the cost: Cheap price of Aluminium molds is a major benefit. It is cheaper than Steel molds.

• *Production time: The time taken for producing aluminum molds is fast than the steel molds. Three to four weeks is enough for producing aluminum mold when compared to steel molds

• *Withstanding power: Aluminium molds withstand for many years even after many shots when compared. The durability feature of aluminum is good than steel. Aluminum has a durable feature in an enhanced way.

• *Pricing: A great advantage of using Aluminiu mold is its low-cost factor. Yes, initial tool investment for Aluminum mold is comparatively cheap.

• *Modifications: The modification of aluminum is tough. Hence, aluminum is used for parts. Hence, design changes are not required in this case. The parts do not require many changes. Easy modifications and receptive nature to repair of aluminum is a major benefit.

• *Heat dissipation properties: Aluminium has excellent heat dissipation properties and it does not require cooling lines. So, the cost of maintenance is very low for aluminum. Hence, the machine setup work is not required.

• *Resin materials: The suitability of advanced resins is high for aluminum. Many materials are used by aluminum mold such as LCP, POM.

• *Low volume feature: As far as low volume production is considered, aluminum offers the greatest value.

• *Heat and cooling time: Aluminium offers quick heating and cooling time when compared.

• *Longevity: Aluminiu tools have a lengthier longevity feature. Also, the flexibility feature of aluminum is great.

The above benefits of aluminum give you a clear indication about using the material. Aluminum material has an edge over using steel material. Comparing the benefits of both aluminum and steel material is a must for mold injection techniques. Choosing the right material for the mold injection process is decided after going through the above advantages.

Many individuals get confused a lot about using aluminum or steel material for the injection molding process.

Aluminum Molds vs. Steel Molds

You might be confused about using the right material for injection molding. You shall find it tough to decide the right fit for your product such as aluminum or steel mold. You shall consider both advantages and disadvantages of aluminum and steel for your injection molding process. Weigh the merits and features of both materials so that you shall come to a conclusion at last. You shall consider both materials for your production need and decide the compatibility part as per your requirement.

Aluminum is not a hard material, and hence it is made into new shapes as desirable. The vital advantages of aluminum such as heat and rust-resistant, and lightweight may help you choosing aluminum. Steel is also a popular and compatible material for mold production.

Value the advantages and disadvantages of aluminum and steel materials. Once your analysis is over take a concrete decision about the materials for mold production.

Let us summarise the advantages of both aluminum and steel for your analysis.

Advantages for Aluminum Molds

• *Aluminum has a lower tooling cost when compared to steel material. When you compare the cost, aluminum is best for your production.

• *The risk of defects is low in aluminum when compared to steel material.

• *Repair and changes are easier in aluminum when compared to steel material.

Advantages for Steel Molds

• *Steel is suited for high-volume production because of its high strength fact.

• *Ideal for detailed features

• *Perfect material for advanced resins.

• *The durability part of steel is great.

Asides from the advantages, the disadvantages of steel and aluminum are also analyzed.

• *Aluminum is not suitable for complex injection molding resins like steel material.

• *Unfit for highly detailed features like steel material.

• *Steel’s cost and are prone to defects and warping.

• *Initial tooling investment is high for steel when compared to aluminum.

You shall consider the above features and points for your decision. You shall weigh the above suggestions for deciding steel and aluminum material for mold production.

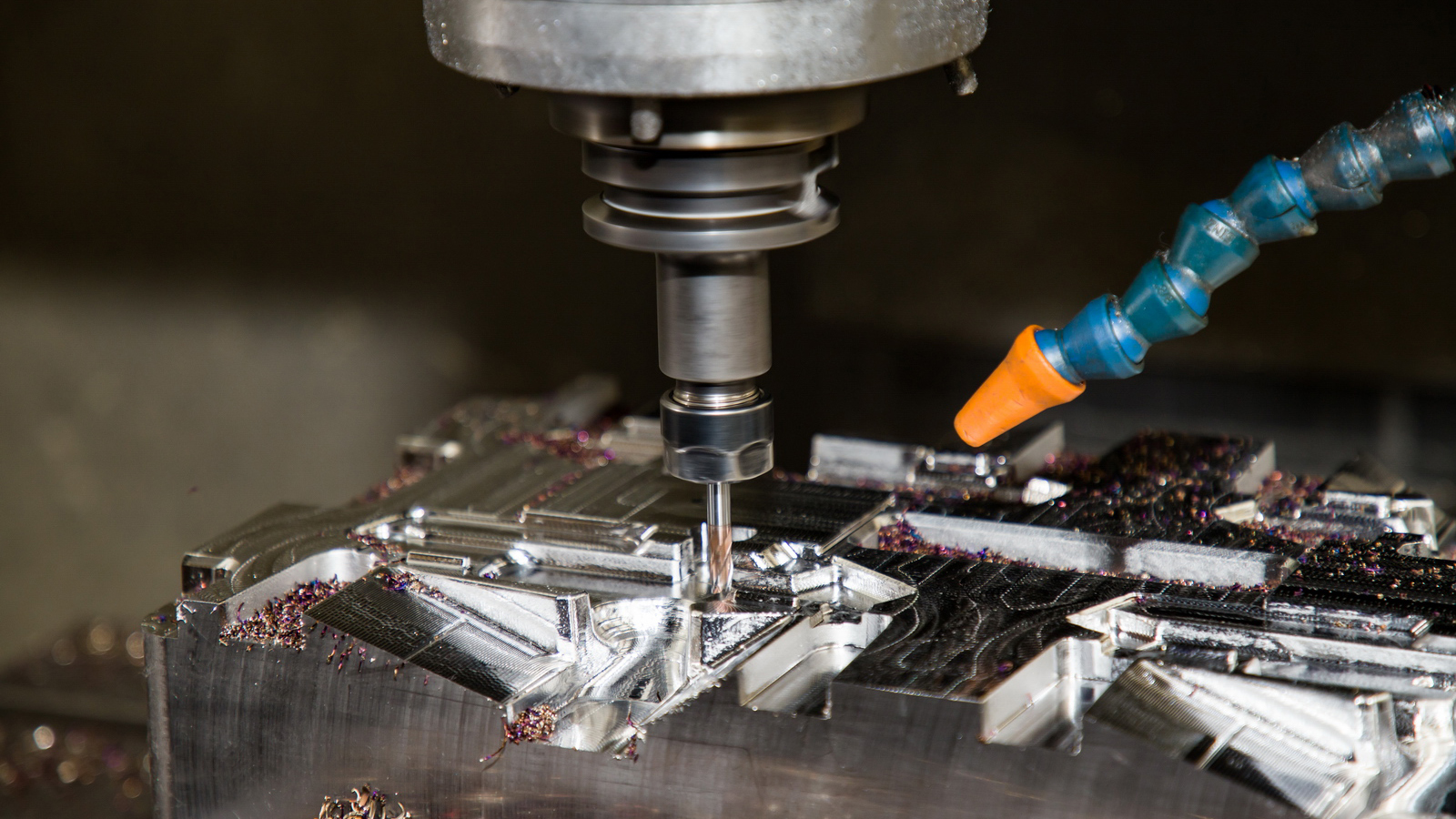

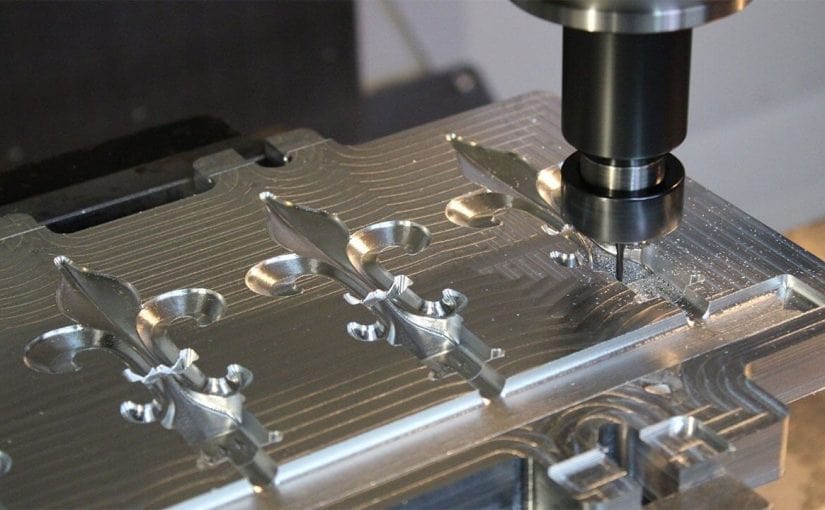

Choosing the Right Aluminum Alloy for Injection Molds

Choosing the right aluminum alloy needs your careful ideas and expertise. Yes, you know better that aluminum has many advantages to produce injection mold. An important point to be remembered by you is that not all alloys of aluminum are equal in creation. A lot of differences exist in aluminum alloys in terms of production and manufacturing.

For low-strength mold applications, using non-heat aluminum materials are essential. You shall select high-strength aluminum alloy for the injection mold production process. To cope with the process, you shall consider the following factors for better results.

Mold production success depends upon the following factors:

• *Resin’s compatibility for aluminum

• *Quantity requirment for mold production

• *Have to know the favorable cycle time

• *Lasting duration for mold

• *Have to understand the configuration of the molding part.

The above factors need to be taken into consideration for mold production success.

Yes, aluminum is always considered the right choice considering the availability and cost. Machining ease is always better with aluminum material. Also, the following features give you an exact solution for your question of choosing the right aluminum alloy

The thermal heat transfer property of Aluminum is higher when compared. This reason is considered one of the best features for aluminum alloy selectors. Due to this reason, lots of advantages are available for the production of injection molds.

Cycle time savings’ Productive improvement is high.

Aluminum has excellent polishing characteristics. Machining characteristics are also high on using aluminum, inclusive of machining ratings.

The heat-treating process is not necessary for aluminum materials. The reason is that the process has been mover during the manufacturing stage itself. Also, the stress-relieving process is over during the manufacturing stage.

Why aluminum alloy creation is not equal?

The following reasons give you the clues why alloys are not created equal

• *Lighter weight

• *Faster machining

The above reasons give you an idea about aluminum alloys’ unequal stages. You shall also understand that alloys of aluminum differ vastly during the manufacturing process or the way produced.

How to Properly Maintain Aluminum Injection Molds?

A lot of factors are considered for aluminum tooling maintenance. The factors such as:

• *Resing type selection for molding

• *Tools’ mechanical action

• *Type of gate for the molding process

• *Addition of coating

The above factors are inevitable for determining the maintenance schedule. Considering Aluminum molds are cleaned every time after running. Cleaning the molds after removing them from the press is important for its maintenance schedule. It is highly essential to check for wear and galling every time the mold is removed.

Following all the essential routine maintenance functions are vital as far as aluminum molds are considered.

What are the major routine maintenance benefits?

• *The optimal performance feature is elevated

• *High-quality parts are also improved

• *Thermal advantages of aluminum get improved

Conclusion

There are two options for a producer of injection molds, such as aluminum or steel. Based on the above suggestions and ideas, one can understand clearly his choice further. The choice of using steel or aluminum depends upon the professionals who are involved in making injection mold.

Each material has its own feature, advantages, and disadvantages after careful analysis. Hence, depending upon the factors discussed above, choosing the best material for injection mold is best. Aluminum material has many features and merits to consider for producing injection mold. In case if anyone needs suitable advice on the type of material to use they shall consult an expert who has profound experience in the injection mold field.

The above Aluminum Injection Molding benefits are valued for your understanding. Consider the ways by which aluminum stands atop when compared to steel material. If you understand the properties of aluminum, you shall consider the material definitely for your injection mold process.

You shall also understand the following points for your clarity

• *Longevity of aluminum injection mold

• *Types of materials used for aluminum injection mold

• *The number of parts aluminum parts make

The above points are a must for a production person to cope with the good results at the end. Choosing the aluminum material is a better choice for the mold injection process than preferring steel. This decision is arrived at after considering various factors listed above. The choice of aluminum over steel has arrived after several rounds of thought and calcucaltion. Above all, the merits of aluminum material are high than steel material. Calcualtively, the wide range of uses and other functional features of aluminum are far better than steel materials. Low tooling costs and quick heating and cooling features of aluminum are major highlights.

Above all, cheaper price and abundant availability of aluminum do not miss your focus and attention to use it without fail. A detailed discussion as found above make your expectations fulfilled about aluminum injection mold

Mastars Industries CO., LTD

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210689

Fax: +86 755-8821 0685

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China

Contents

Mastars

Aluminum

CNC machining

injection molding

prototyping