-

-

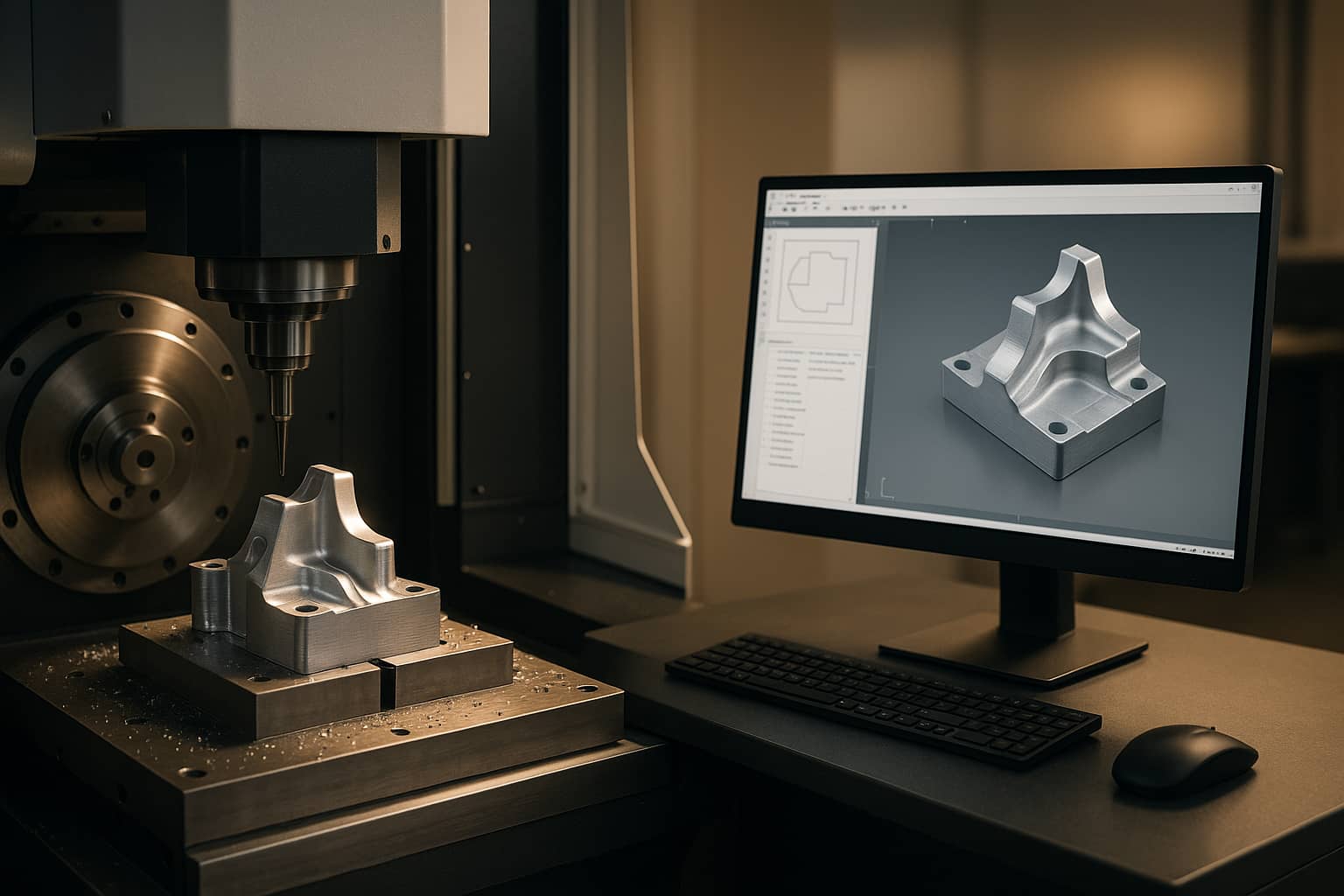

Automation in CAD/CAM: Benefits for CNC MachiningAutomation in CAD/CAM is transforming CNC machining by improving efficiency, accuracy, and reducing costs. Here's what t...

-

-

Advantages of CNC Machining for Rapid PrototypingMastars is a global company that provides one-stop customized industrial manufacturing services. Its business scope is a...

-

-

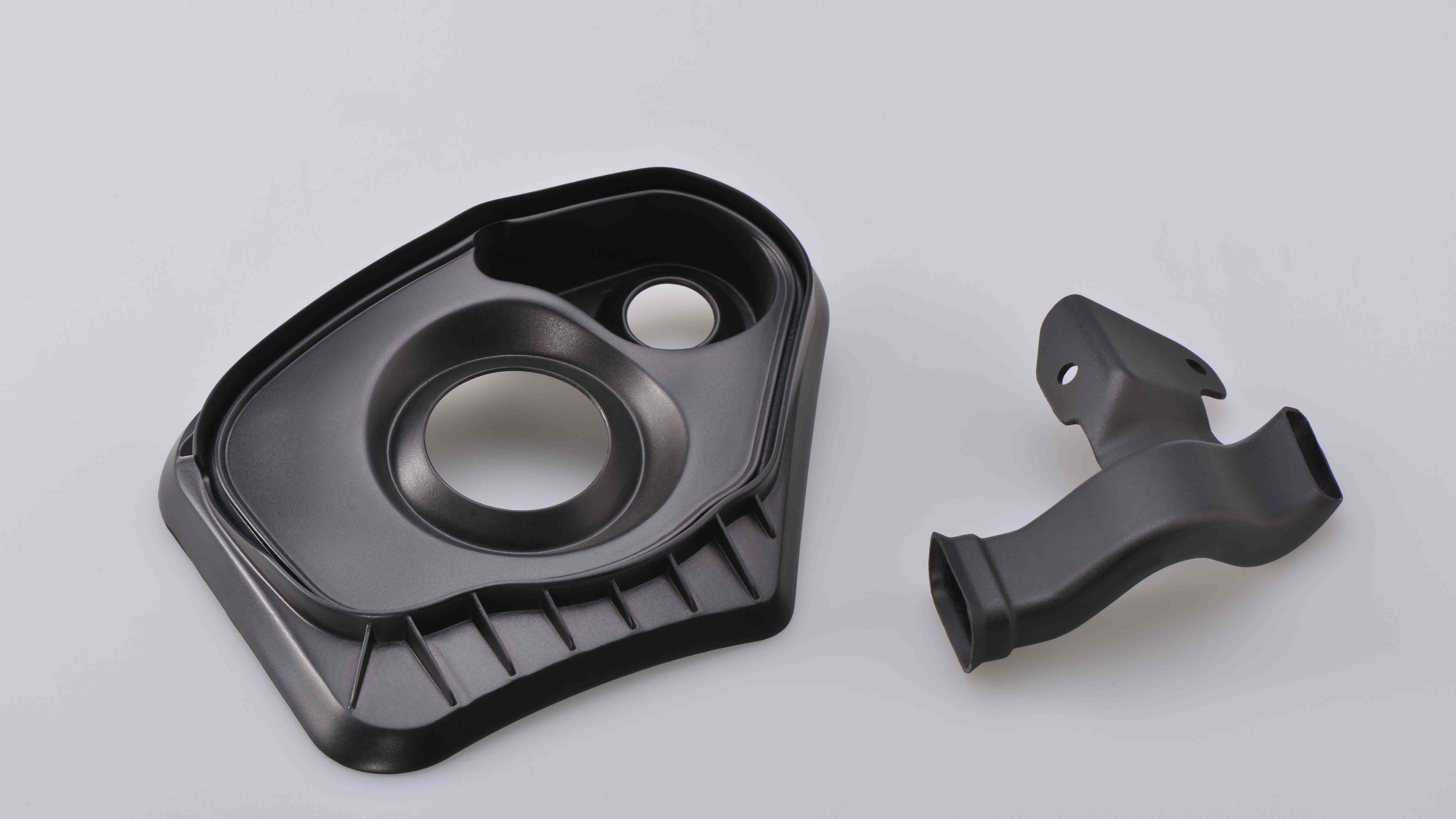

characteristics of metal stamping die|Custom metal stamping|MastarsMastars business scope: rapid cnc service,custom metal stamping,rapid sheet metal prototyping ,shell mold, hardware spri...

-

-

Tighter Tolerance Requirements Promote Micro Molding Technology Innovation|CNC machining company |CNC machining services|Customized 3D Printing Service ?Materials research is still one of the m...

-

-

Mastars|Application of injection molding technology in automobile fieldInjection molding technology has some special properties, such as precision, environmental protection, resource saving, ...

-

-

Sustainable Mold Assembly Practices: Reducing Carbon FootprintUnder EU CBAM policy, Mastars adopts sustainable mold assembly practices and carbon management to achieve green manufact...

-

-

Bioness

-

-

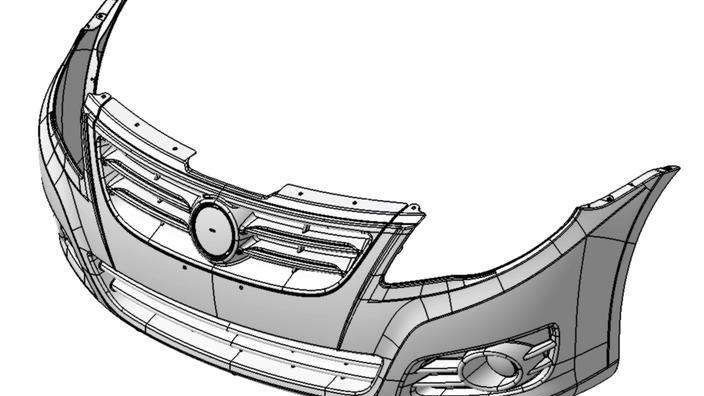

Why should the car bumper be made of plastic?|rapid cnc machining|prototypingMastars is dedicated to the extrusion, injection molding, and machining of various plastic products. We specialize in PE...

-

-

Key Insights to Drive ExcellenceMastars kicked off September with a focused morning meeting, where leaders shared actionable tips for efficiency and ser...

Contact us

- Building 6 , Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City,Guangdong, China (518104)

- marketing@mastars.com

Detailed introduction to Pressure die Casting

Here is a detailed

introduction to Pressure Die Casting.

Pressure Die Casting: A Detailed Overview

1. Executive Summary

Pressure Die Casting, often simply called die casting, is a high-volume manufacturing process for

producing precisely detailed, dimensionally accurate metal parts. It involves

forcing molten metal under high pressure into a reusable steel mold, known as a die. The combination of high pressure and rapid

solidification allows for the production of complex, thin-walled components

with excellent surface finish and high production rates. It is the dominant

process for mass-producing non-ferrous metal parts, especially those made from

zinc, aluminum, and magnesium alloys.

2. Core Principle & Key Characteristics

The fundamental

principle is the use of persistent, high pressure to fill a die cavity completely and rapidly before the metal solidifies.

Key Characteristics:

-

High Pressure: The

defining feature. Pressure is used not just to fill the cavity but to hold

the metal under pressure during solidification, resulting in a dense,

pore-free part.

-

Rapid Production: Cycle times are very short (seconds to minutes), making it ideal for

volumes ranging from thousands to millions of parts.

-

Excellent Dimensional

Accuracy: The use of precision-machined steel

dies produces parts with tight tolerances and minimal variation.

-

Thin Walls &

Complex Shapes: The high injection pressure allows the

molten metal to fill very thin sections and intricate details that would

be impossible with other casting methods.

-

Superior Surface

Finish: Parts have a smooth surface directly

from the die, often minimizing the need for post-machining.

3. The Two Main Processes: Hot vs. Cold Chamber

The process is

divided into two main variants, distinguished by how the molten metal is

injected into the die. The choice depends primarily on the melting point of the

alloy being cast.

1. Hot-Chamber Die Casting

-

Principle: The

injection mechanism (a gooseneck and piston) is permanently immersed in a

pool of molten metal.

-

Process:

-

The piston is retracted, opening the

port and allowing molten metal to fill the "gooseneck."

-

The piston moves forward, forcing the

metal through the gooseneck and into the die cavity.

-

After the metal solidifies, the piston

retracts, and the cycle repeats.

-

Advantages: Faster cycle times, higher production rates, easier automation, less metal

oxidation.

-

Disadvantages: The

immersed components are attacked by molten metals with high melting

points, limiting material compatibility.

-

Typical

Applications: Ideal for alloys with low melting points,

such as Zinc,

Magnesium, and Lead alloys.

2. Cold-Chamber Die Casting

-

Principle: The

molten metal is held in a separate furnace. A ladle is used to transfer a

precise amount ("shot") of metal into a "cold

chamber."

-

Process:

-

Molten metal is ladled from the furnace

into the injection cylinder (the cold chamber).

-

A hydraulically powered piston advances

rapidly, forcing the metal into the die cavity.

-

The metal is held under high pressure

until it solidifies.

-

Advantages: Suitable for metals with high melting points that would attack the submerged components of a hot-chamber machine.

-

Disadvantages: Slower cycle time due to the ladling step; potential for more metal

oxidation.

-

Typical

Applications: Used for alloys with higher melting

points, primarily Aluminum and Copper

(Brass/Bronze) alloys.

4. The Pressure Die Casting Cycle

The cycle is a highly automated sequence:

-

Die Closing: The

two die halves are hydraulically clamped together with immense force.

-

Injection: Molten metal is injected into the die cavity. This phase has two stages: a

high-speed phase to fill the cavity, followed by an intensification phase

that applies extreme pressure.

-

Solidification

(Cooling): The metal cools and solidifies rapidly

in the water-cooled die.

-

Die Opening: The

die halves separate.

-

Ejection: Ejector pins push the finished casting out of the die.

-

Lubrication

(Spraying): A release agent is sprayed onto the

die cavity to aid the next part's ejection and to cool the die surface.

The cycle then repeats.

5. Key Components of the System

-

Die (or Tool): The

reusable steel mold, typically made from two halves:

-

Cover Die (Fixed Half): Attached

to the fixed platen of the machine and contains the sprue hole for

injection.

-

Ejector Die (Moving Half): Attached to the moving platen and contains the ejection system.

-

Cavity: The

hollow impression in the die that forms the casting.

-

Cores: Movable components in the die that form internal features like holes. They

can be retracted before the part is ejected.

-

Shot Sleeve (Cold

Chamber): The cylinder into which molten metal

is ladled in a cold-chamber machine.

-

Plunger (Piston): The

component that pushes the molten metal through the shot sleeve/sprue and

into the die.

-

Ejector Pins: Pins that push the solidified casting out of the ejector die half.

-

Overflow Wells &

Vents: Small cavities in the die that trap

impurities and allow air to escape during injection.

6. Advantages and Limitations

|

Advantages |

Limitations |

|

Very high production rates. |

High initial cost for die tooling. Dies are

complex and expensive. |

|

Excellent dimensional accuracy and

consistency. |

Limited to non-ferrous metals (primarily Zn,

Al, Mg). |

|

Ability to produce complex shapes with thin

walls. |

Part size is limited by die size

and machine clamping force. |

|

Smooth cast surfaces (typically

1-25 µm Ra). |

Porosity can be an issue. While high pressure

reduces porosity, internal micro-shrinkage can still occur, making parts

unsuitable for high-integrity structural applications without secondary

processing. |

|

Minimal machining required (near-net-shape process). |

Not economical for low volumes. |

7. Comparison with Other Processes

|

Feature |

Pressure Die Casting |

Gravity Die Casting (Permanent Mold) |

Sand Casting |

|

Pressure Source |

High-pressure piston. |

Gravity. |

None (or low pressure in low-pressure die

casting). |

|

Mold |

Reusable, precision steel die. |

Reusable, permanent metal mold. |

Disposable sand mold for each part. |

|

Production Rate |

Very High. |

Medium. |

Low. |

|

Surface Finish |

Excellent. |

Good. |

Rough. |

|

Dimensional Accuracy |

Excellent. |

Good. |

Fair. |

|

Part Complexity |

Very High (thin walls,

fine details). |

Moderate. |

Moderate to High. |

|

Cost Driver |

High tooling cost, low per-part cost. |

Medium tooling cost, medium per-part cost. |

Low tooling cost, high per-part cost

(labor). |

8. Common Applications

-

Automotive: Transmission housings, engine blocks, cylinder heads, wheels, brackets.

-

Consumer

Electronics: Laptop and phone chassis, heat sinks,

internal brackets.

-

Appliances: Gearbox housings for power tools, components for washing machines.

-

Hardware: Faucet parts, door handles, locks.

Conclusion

Pressure Die Casting is the premier

manufacturing method for producing high volumes of complex, high-integrity

metal components with exceptional efficiency and precision. While the initial

investment in tooling is significant, its unparalleled production speed,

dimensional accuracy, and excellent surface finish make it the most

cost-effective choice for mass-producing parts from non-ferrous metals.

【Editor】:Mastarsall rights reserved:https://www.mastars.comPlease indicate the source