What is the most difficult material for sheet metal bending

Mastars often uses the sheet metal process to make prototypes and carry out mass production. The sheet metal process is simple and efficient. We have introduced the advantages of sheet metal process. As a common process, let's have a further understanding.

To make rapid sheet metal prototypes, many kinds of commonly materials can be used, and almost all sheet metal materials need to be bent. The bending process of each material is different. The precautions are also different. Let's briefly describe the bending process of various sheet metal materials.

1.Carbon steel plate, i.e. SPPC cold rolled steel plate. SPPC cold rolled steel sheet is the most commonly used material in

sheet metal processing, and it is also the easiest material to realize sheet metal bending process. Because of its good ductility, it is especially suitable for sheet metal bending. In addition, the SPPC board needs subsequent surface treatment, which can cover up the defects caused in the bending process. It is the easiest material to bend.

2. Stainless steel plates are commonly used, such as SUS201, SUS304, SUS316, 1Cr17, etc. Because stainless steel has strong anti rust ability, it can be used in humid environment or outdoors without surface treatment. There are new requirements for sheet metal bending. Generally speaking, for the perfect view of sheet metal processing, the surface is required to be free of scratches and creases. During normal sheet metal bending, there will be sliding friction between sheet metal material and bending lower die, which is easy to form creases.

3. Aluminum and copper plates. These two materials are somewhat similar to stainless steel. Scratch and indentation are not allowed on the general surface. Another point is that bending is easy to crack. Generally, there are no cracks in red copper plate, while brass plate is poor, and cracks are easy to appear in bending of many models of aluminum plate.

4. Hot rolled steel plate. Due to the material properties, the above materials need to be operated by different bending processes. Hot rolled steel plate is the most difficult material in bending. Hot rolled steel plate is SPHC, because a hard layer of Fe3O4 will be formed on the surface during rolling. The mechanical properties and elongation of internal materials are not very good, and cracks are easy to appear in the bending process.

Another problem is that if you buy cheap materials for hot-rolled steel plates, the quality is unstable, the internal mechanical properties are inconsistent, and the material thickness of the same plate is inconsistent. The bending angle varies from big to small. The same bending angle is inconsistent and full of uncertain factors. Therefore, it is listed as the most difficult material for sheet metal bending.

Mastars:

We employ proven prototype technologies(Sheet metal,

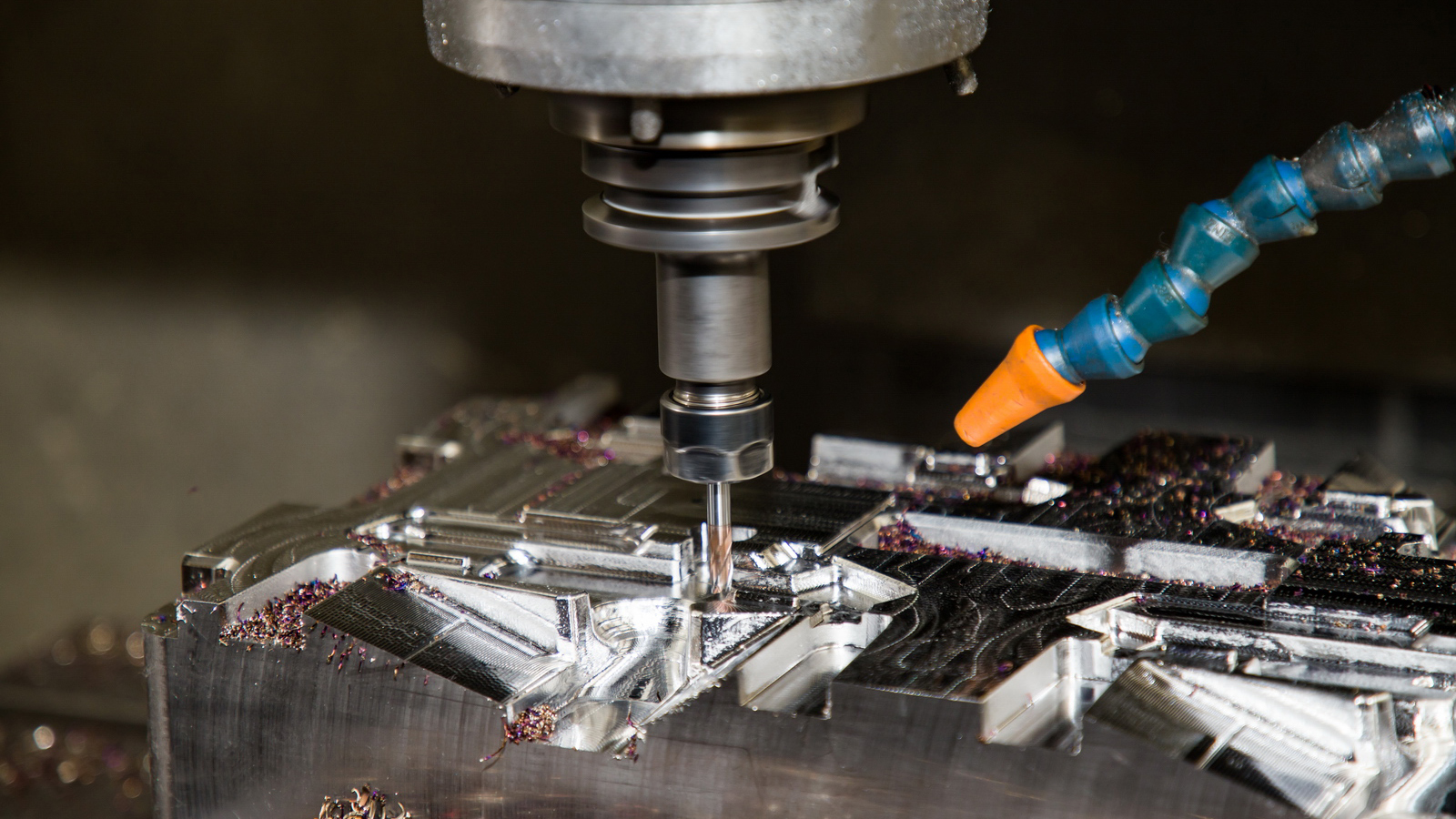

CNC machining,

Vacuum casting,

3D printing etc.), to take new concept or design and bring it to life, develop and evaluate new products quickly, economically and with less risk. With lesson learn from prototyping, we provide considered and proactive tooling design/build and mass production processing, from injection molding, die casting, CNC machining to final assembly as full one-stop solution.

Our purpose is to make great products for our customers that create value and improve people's lives. We help a diverse customers base design, build and deliver the products that make the world a better place.

Our vision is to be the most reliable and valuable manufacturer supplier in the world.

Mastars Industries CO., LTD

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210690

Mobile: +86 181 0029 4997

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China