Rapid prototyping enables automotive manufacturers to quickly iterate designs

In the highly competitive automotive industry, innovation is the lifeblood. The ability to swiftly transform groundbreaking concepts into physical prototypes has become a decisive factor in determining a company's competitiveness. Rapid prototyping, with its unique advantages, is revolutionizing the operational models of automotive manufacturers and injecting new impetus into the future development of the industry.

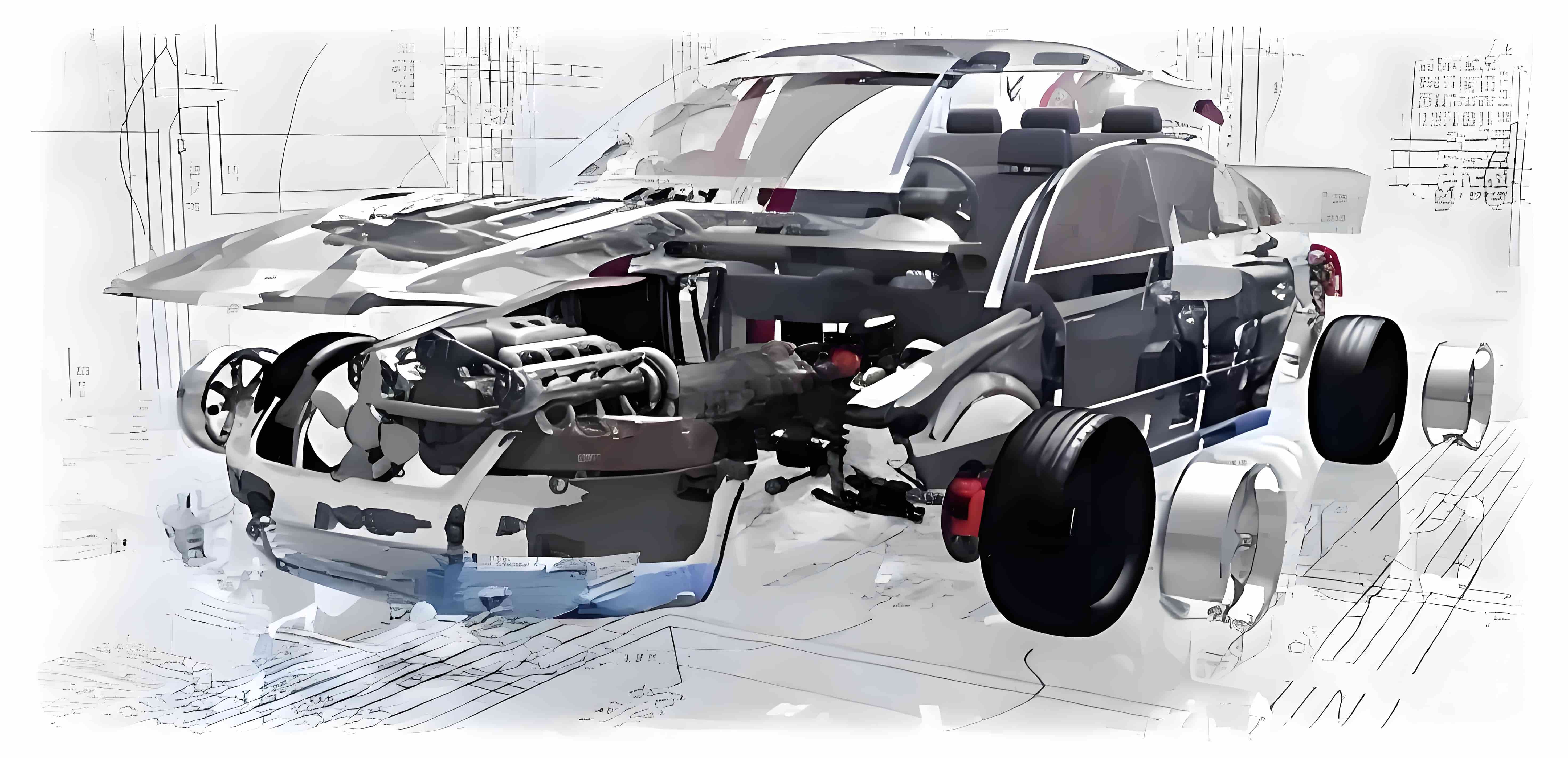

The development of the automotive industry has always been closely linked to advancements in manufacturing technology, and rapid prototyping lies at the heart of this transformation. Traditional prototyping methods in automotive manufacturing were plagued with numerous drawbacks: they were extremely time-consuming, often taking weeks or even months; costs were sky-high; and they severely restricted design innovation. The advent of rapid prototyping has completely reversed this situation.

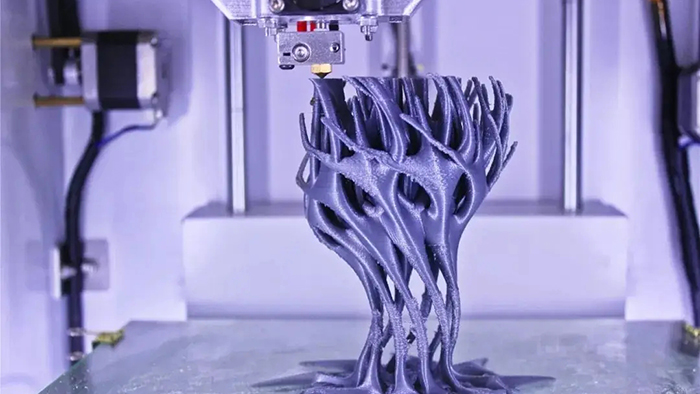

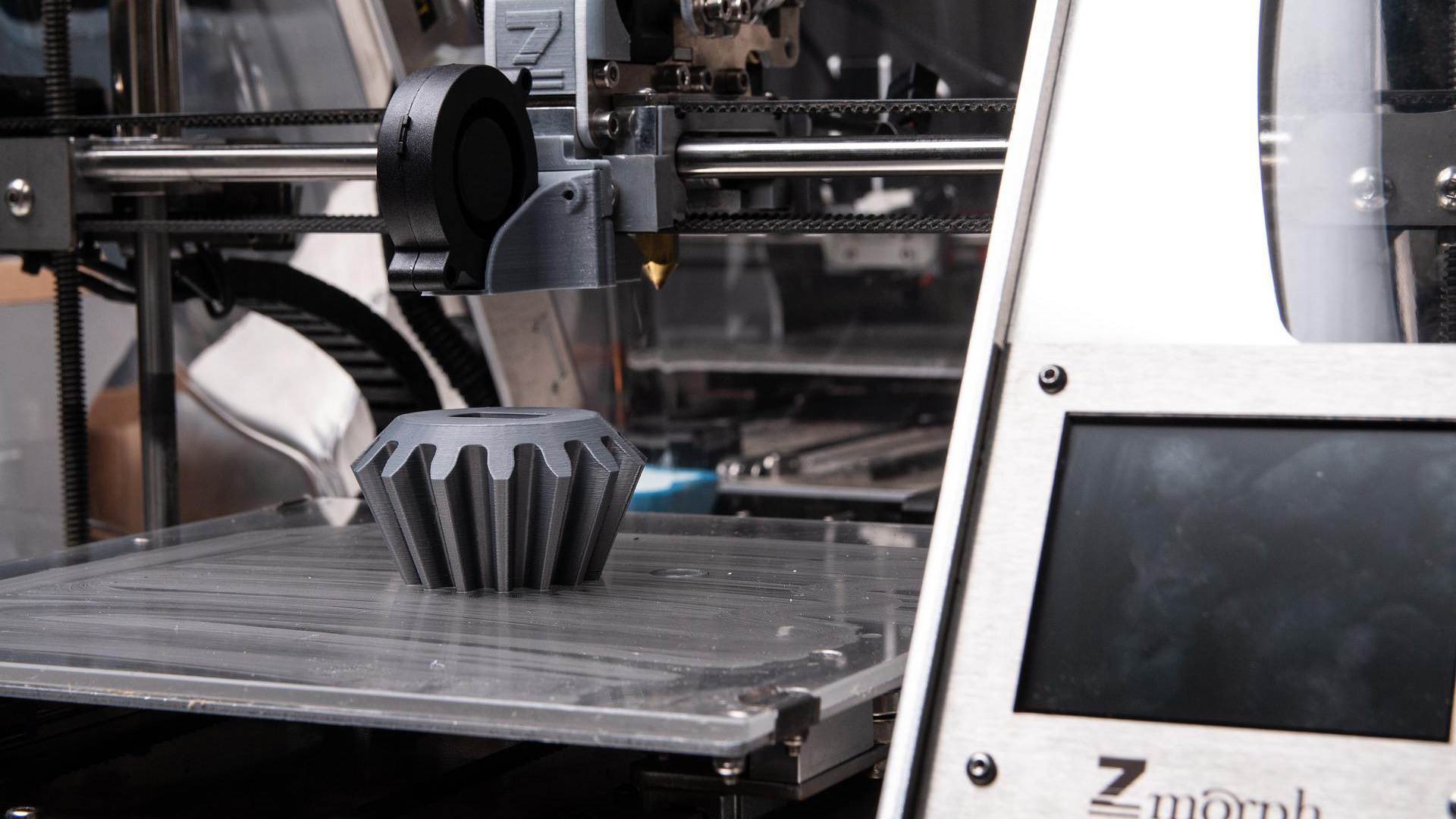

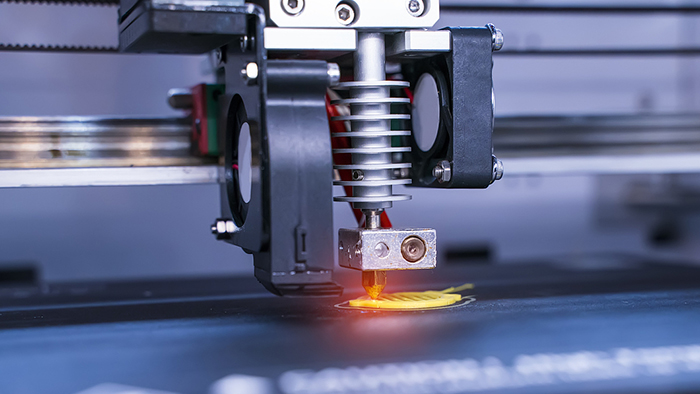

Additive manufacturing enables complex automotive components to be produced quickly

Additive manufacturing, the core technology of rapid prototyping, enables the layer-by-layer construction of parts. It directly bypasses the complex processes of tooling and mold making. This allows engineers to quickly translate their design concepts for components such as engine parts and dashboard assemblies into physical entities, significantly shortening the development cycle.

The combination of CNC machining and rapid prototyping offers even more advantages. CNC machining excels in high-precision surface finishing, while rapid prototyping is proficient in creating complex geometries. The synergy of these two manufacturing processes ensures that prototypes not only meet the industry's stringent dimensional and performance standards but can also be produced rapidly.

In the past, if a flaw was detected in a prototype, it was necessary to remake the tooling and restart the entire process. Now, with rapid prototyping, digital design modifications can be made, and a new prototype can be produced within a few days. This enables more efficient testing and optimization, ensuring higher-quality final products.

A common concern in the industry is how to reduce automotive prototyping cost with rapid technology, and rapid prototyping provides a clear answer. By eliminating expensive tooling and producing only the necessary prototypes for testing, waste is reduced, and overall development costs are lowered. This cost-saving aspect provides automotive companies with the financial flexibility to invest in emerging fields such as electric vehicle technology and autonomous driving systems.

The automotive markets in Europe demand high-quality, innovative vehicles and place great emphasis on cutting-edge technology and efficient manufacturing processes. Rapid prototyping enables companies to quickly adapt to market trends. For instance, in response to the demand for eco-friendly vehicles with specific interior features, rapid prototyping enables companies to rapidly develop and test new component prototypes.

Custom interior components created through rapid prototyping

Supply chain optimization is another major benefit brought about by rapid prototyping. Companies can produce prototypes locally and quickly, reducing their reliance on distant suppliers. This shortens the lead time of the supply chain and enhances the resilience of the development process against disruptions, which is particularly crucial in Europe where supply chain optimization is highly valued.

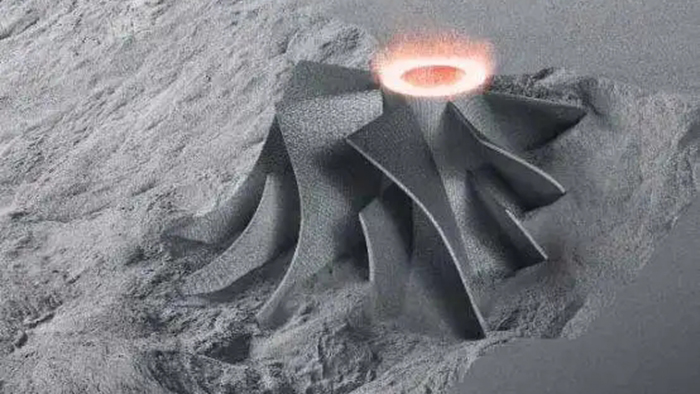

In terms of advanced materials, rapid prototyping demonstrates its powerful capabilities. Whether it is high-strength alloys or lightweight composites, prototypes can be made through this process, facilitating the testing of their potential in enhancing vehicle safety, fuel efficiency, and durability. As the automotive industry transitions towards electrification and intelligence, the demand for innovative advanced materials is surging, and rapid prototyping serves as an ideal platform for their evaluation and integration.

The role of rapid prototyping in the automotive industry will continue to expand. Technological progress will bring faster printing speeds, better material properties, and deeper integration with other manufacturing systems. In the future, companies will not only be able to complete prototype production within days but also utilize this technology for small-batch production of customized parts, further blurring the boundaries between prototyping and large-scale manufacturing.

The future of automotive manufacturing with rapid prototyping technologies

In conclusion, rapid prototyping, in close integration with key manufacturing processes such as additive manufacturing and CNC machining, is the core driving force behind the positive development of the automotive industry. It has transformed the prototyping model, achieving fast design iteration, low-cost consumption, and high operational flexibility. In Europe, where innovation and efficiency are highly valued, rapid prototyping is no longer just a tool but a strategic weapon shaping the future of automotive manufacturing.