For Australian engineers and product developers seeking agile and robust manufacturing solutions, Selective Laser Sintering (SLS) stands out as a premier additive manufacturing technology. This process enables the creation of complex, high-performance parts directly from digital models, without the need for tooling. Mastars, as your trusted manufacturing partner in China, leverages SLS to bring your concepts to life with speed and precision.

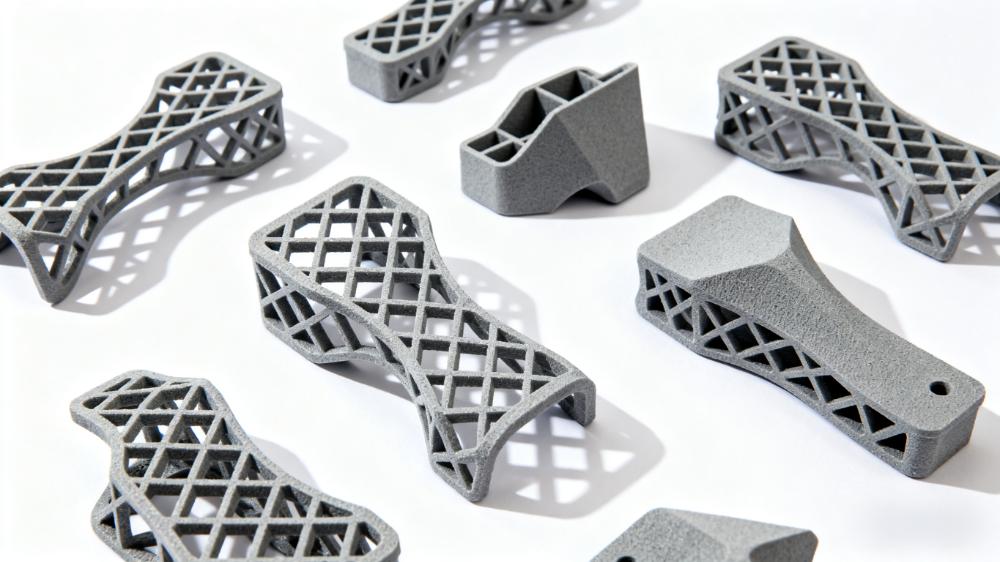

The core of the SLS process involves using a high-power laser to fuse small particles of nylon powder layer by layer, based on a 3D CAD model. This method is distinctly different from other 3D printing techniques as it requires no support structures, allowing for greater design freedom and efficient part nesting. The result is functional prototypes and end-use parts that exhibit excellent mechanical properties and thermal resistance.

One of the most significant advantages of SLS for the Australian market is its ability to produce incredibly durable components that can withstand rigorous testing and real-world application. From automotive brackets under the bonnet to custom medical devices, SLS parts are known for their strength and stability. Mastars expertly manages the entire production workflow, ensuring every part meets stringent quality standards before shipment to Australia.

Speed to market is a critical competitive advantage, and SLS rapid prototyping drastically shortens the development cycle. Design iterations can be produced and tested within days, not weeks, accelerating innovation for Australian businesses. Mastars' streamlined supply chain and extensive experience ensure your projects move from design validation to final production with unmatched efficiency.

Beyond prototyping, SLS is increasingly adopted for low-volume production runs across Australia, offering a cost-effective alternative to traditional injection moulding. This is ideal for bespoke products, spare parts inventory, or market testing without the high initial investment in tools and moulds. Mastars provides a seamless bridge to manufacturing, offering scalable production solutions directly from your digital files.

The material versatility of SLS technology is another key benefit, with materials like glass-filled nylon offering enhanced stiffness and aluminium-filled nylon providing a metallic finish. This allows Australian designers to select the perfect material properties for their specific application, whether for visual models or fully functional assemblies. Mastars offers guidance on material selection to optimise your part's performance and cost.

Choosing Mastars as your SLS service provider connects Australian innovators with top-tier Chinese manufacturing expertise and capacity. We combine state-of-the-art SLS equipment with rigorous quality control processes to deliver parts that meet the highest expectations. Our commitment to reliability and clear communication makes us the ideal partner for your next project.

Ready to transform your manufacturing process with professional SLS services?

Contact UsGet a free consultation and quote for your project