Rapid Tooling (RT): A Detailed Overview

1. Executive Summary

Rapid Tooling (RT) is a broad term for a set of techniques

that use additive manufacturing (3D printing) or other rapid processes to

create molds, patterns, or dies—collectively known as "tooling"—much

faster and at a lower cost than conventional methods. The primary goal of RT is

to produce functional prototypes or low to medium volumes of production parts using the same manufacturing processes intended for mass production (like

injection molding, casting, or stamping), but without the time and expense of

machining solid metal tooling.

It serves as the

critical bridge between Rapid Prototyping (one-off models) and full-scale production.

2. Core Concept & Philosophy

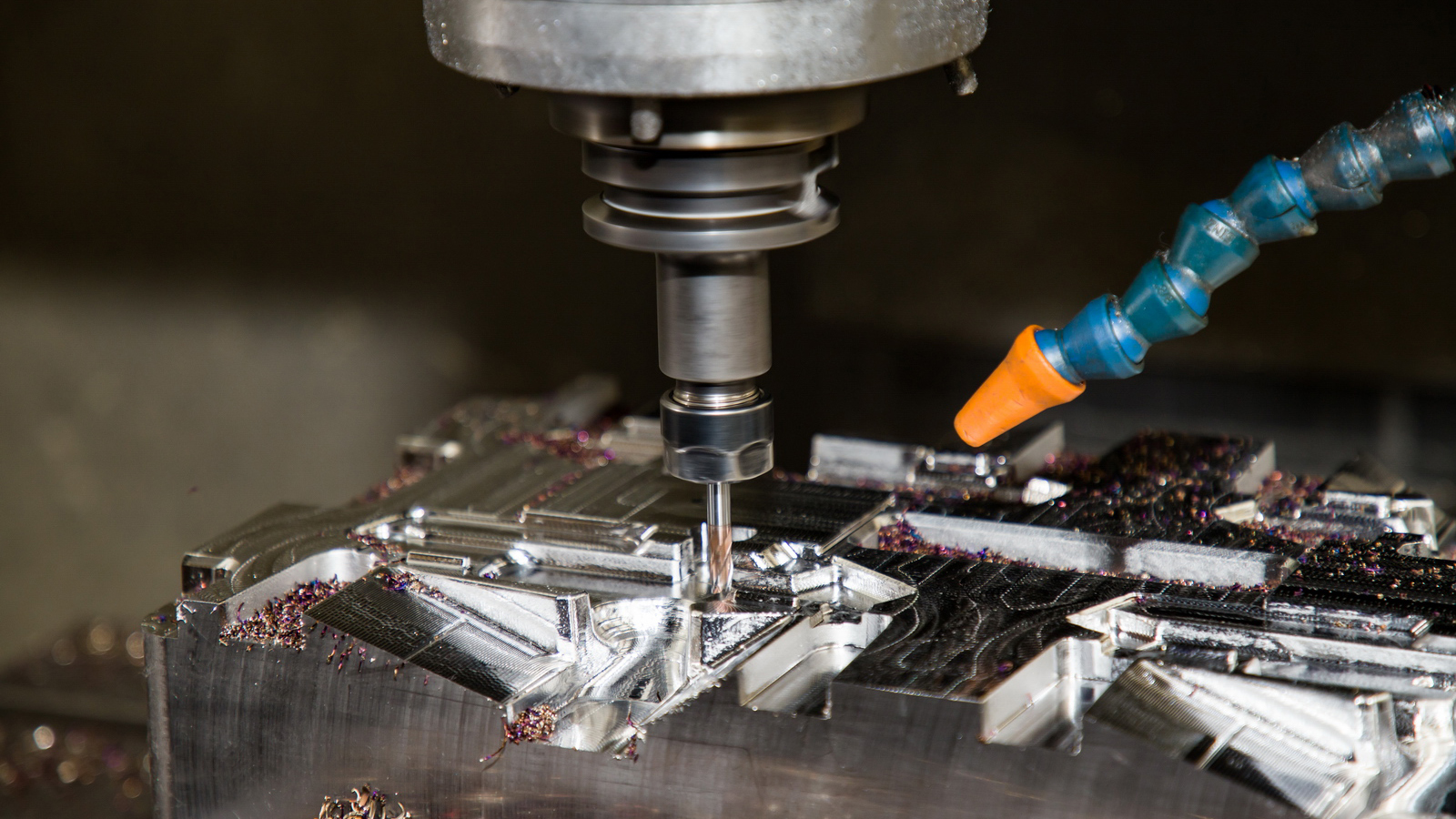

Traditional

tooling (e.g., steel molds for injection molding) is machined from solid blocks

of metal, which is a slow, subtractive process that can take weeks or months

and cost tens of thousands of dollars.

The RT philosophy is to sacrifice the long production life of a

hard tool in exchange for significant savings in time and cost for the initial

phases of product development, validation, and market testing.

3. Classification of Rapid Tooling

Rapid Tooling is

generally divided into two main categories based on the tool's material and

lifespan:

1. Indirect Rapid Tooling

2. Direct Rapid Tooling

4. Key Rapid Tooling Technologies

|

Technology |

Type |

Description |

Typical Applications & Materials |

|

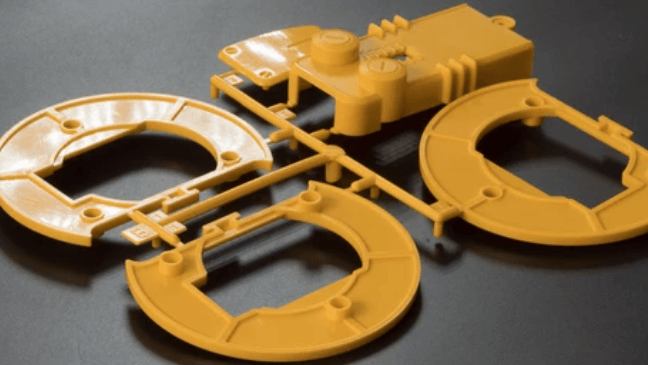

Vacuum Casting |

Indirect |

A 3D printed master is used to create a silicone

mold. Under vacuum, polyurethane resin is poured in to create copies. |

10-25 parts. Ideal for

prototypes that look and feel like injection-molded parts (ABS-like, PP-like,

transparent resins). |

|

3D Printed Sand Molds |

Direct |

A binder-jetting process creates foundry

sand molds layer by layer. The molds are then used in traditional metal

casting. |

Complex metal parts. Casting of

engine blocks, pump housings, and architectural components in aluminum, iron,

and bronze. |

|

RTV Silicone Molding |

Indirect |

Similar to Vacuum Casting but often used

for larger parts or different resins. Room Temperature Vulcanizing (RTV)

silicone is used. |

Low-volume rubber parts, architectural

panels. Polyurethane, epoxy, and actual rubber materials. |

|

Direct Metal 3D Printing (DMLS/SLM) |

Direct |

A laser melts metal powder to build mold

inserts layer by layer. The key advantage is conformal cooling channels. |

Injection mold inserts. Production of

100s to 1,000s of parts. Ideal for high-performance metals (stainless steel,

tool steel). |

|

Spray Metal Tooling |

Indirect |

A thermal spray process deposits a thin

shell of metal (e.g., zinc or aluminum) onto a 3D printed master. The shell

is then backed with a ceramic or epoxy for support. |

Short-run injection molds. Can produce

hundreds of plastic parts. Faster and cheaper than a full steel mold. |

|

Epoxy Composite Tooling |

Indirect / Direct |

A 3D printed pattern is used to create a

mold from an epoxy resin that is filled with materials like aluminum powder

for strength and thermal conductivity. |

Low-volume injection molds, composite layup

tools. Can be used directly in a press to produce a limited run of parts. |

|

Laminated Object Manufacturing (LOM) of

Dies |

Direct |

Sheets of paper or metal are cut and

laminated together to form a rough tool shape. Historically used for sand

casting patterns and low-force stamping dies. |

Patterns for sand casting, paperboard dies

for sheet metal prototyping. |

5. The Killer Feature: Conformal Cooling

This is a major advantage of Direct Metal Rapid Tooling (like DMLS).

6. Advantages of Rapid Tooling

7. Limitations of Rapid Tooling

Conclusion

Rapid Tooling is a cornerstone

of modern agile manufacturing. It enables companies to accelerate

product development, validate designs with functional parts made from

production-like processes, and bring products to market faster. By choosing the

appropriate RT method, engineers can effectively bridge the gap between a

digital design and a physical product while managing cost and risk