Ultimate Guide to Plastic Molding

Mastars is a global company that provides one-stop customized industrial manufacturing services.It has mold making and injection molding technology and has a deep understanding of special engineering plastics. In the field of mold making, we have more than 10 years of experience, cooperated with customers, and completed molds of products with hundreds of different materials and mass production. In this field, we provide different solutions according to materials, and rationally use technology to meet customer needs.

Plastic molding is the process by which plastics in various forms (powders, granules, solutions, and dispersions) are made into products or blanks of the desired shape. There are as many as thirty kinds of forming plastics methods. The following is an introduction to the centralized plastic manufacturing process currently in common use.

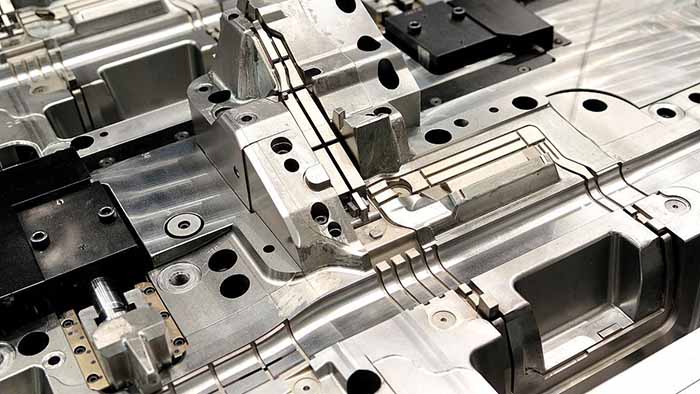

Injection molding is a method of molding industrial products. Products usually use rubber injection molding and plastic injection molding. Injection molding can also be divided into injection molding compression method and die-casting method. Injection molding machine (abbreviated as injection machine or injection molding machine) is the main molding equipment that uses plastic molding molds to make various shapes of plastic products from thermoplastics or thermosets. Injection molding is achieved through injection molding machines and molds.

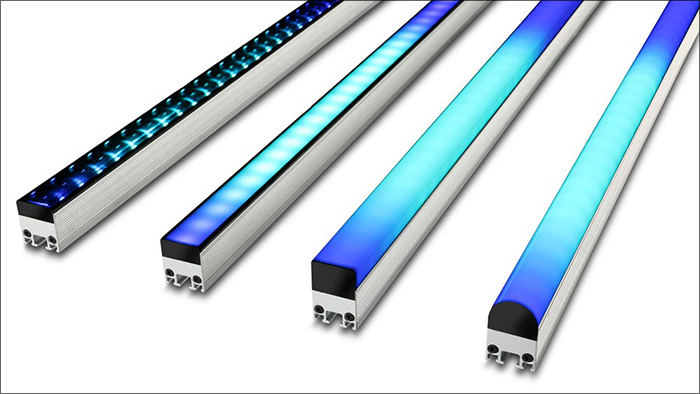

Plastic extrusion is a kind of processing method through the action between the extrusion barrel and the screw, the material is heated and plasticized, while the screw is pushed forward, continuously through the machine head and made into various cross-section products or half products.

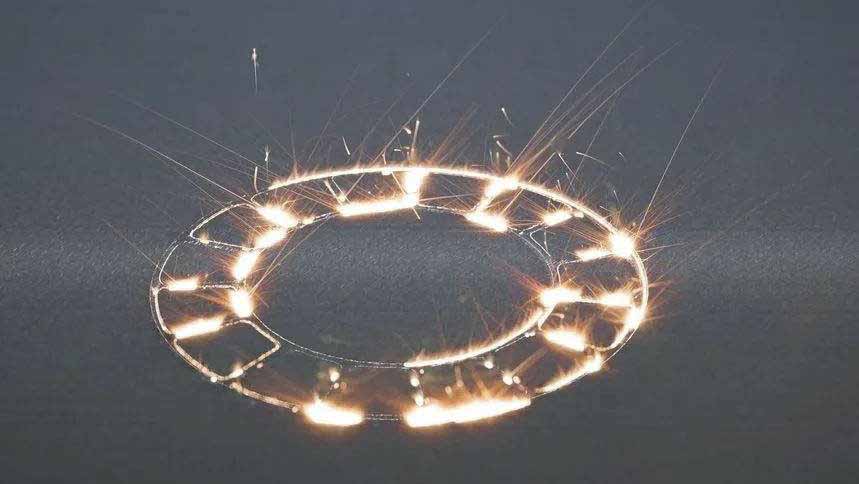

Compared with other molding processes, the rotational molding process provides us with more design space. With the right design concept, we can combine several parts into a complete mold, which greatly reduces the high assembly cost. The method of rotary molding is to first add a measure of plastic (liquid or powder) to the mold. After the mold is closed, it is rotated along the two vertical rotation axes, and the mold is heated at the same time. Under the action of gravity and heat energy, the plastic raw materials in the mold are gradually evenly coated, fused, and adhered to the whole surface of the mold cavity, and then formed into the same shape as the mold cavity. After cooling and shaping, the mold is demoulded to obtain the desired shape of the products.

Blow molding, also known as hollow blow molding, is a rapidly developing plastic processing method. The tubular plastic billet obtained by extrusion or injection molding of the thermoplastic resin is placed in the split mold while it is hot (or heated to the softening state), and compressed air is injected into the billet immediately after the mold is closed to make the plastic billet blow and stick to the inner wall of the mold. After cooling and demoulding, a variety of hollow products are obtained.

Vacuum forming is a kind of plastic processing technology; the main principle is that the flat plastic sheet becomes soft after heating, using vacuum adsorption on the surface of the mold, after cooling forming. It is a kind of technology applied in all walks of life.

Compression molding is also known as pressing molding. It is done by placing powdery, granular, or fibrous plastic in a mold cavity at molding temperature, then closing the mold and pressing it to form and solidify. Compression molding can also be used for thermosetting plastics, thermoplastics, and rubber materials.

Calendaring molding is a process in which the melt plasticized thermoplastic is extruded and extended by the roller through two or more parallel-opposite rotating roller gaps to make the melt become continuous sheet products with certain specifications and sizes and meet the quality requirements. Finally, it is formed by natural cooling. Calendering molding process is often used in the production of plastic film or sheets.

Foaming molding is a process in which foaming materials (PVC, PE, and PS, etc.) are added with appropriate foaming agents to produce microporous structures of plastics. Almost all thermosetting and thermoplastic plastics can be made into foamed plastics, and foaming molding has become an important field in plastic processing.

The winding forming process is to wind the continuous fiber (or cloth tape, prepreg yarn) soaked in resin glue solution to the core mold according to certain rules. After curing and demoulding, the product is obtained.

Laminated molding is a kind of molding process in which multiple layers of the same or different materials are combined with the whole under heating and pressure. Often used in plastic processing, also used in rubber processing.

Coating molding is the plastic sol or organic sol daub on the surface of the substrate such as cloth or paper. Make imitation leather products, varnished cloth or plastic wallpaper, etc, or the process of applying powdery plastic to metal surfaces. Common plastic coating products are artificial leather, lacquer cloth, plastic wallpaper, and all kinds of metal coating products.

Pouring molding is a method of plastic manufacture processing. The early casting is to inject liquid monomer or prepolymer into the mold under normal pressure and solidify into products with the same shape as the mold cavity after polymerization. With the development of molding technology, the traditional casting concept has changed. Polymer solutions, dispersions, polyvinyl chloride pastes and melts can also be used for casting.

Dripping technology uses thermoplastic polymer materials with variable state properties, that is, they have viscous fluidity under certain conditions, and they can restore solid properties at room temperature, and use appropriate methods and special tools to inkjet. Under the state of viscous flow, it is shaped into the designed form as required, and then solidified and shaped at room temperature.

Cold press molding is a type of compression molding. Different from ordinary compression molding, the material is pressure-molded at room temperature. After demolding, the molded product can be reheated or cured by chemical action.

This technology has developed rapidly in recent years, and has been widely used in the aircraft industry, automobile industry, ship industry and other fields, and has developed many branches such as RFI, VARTM, Scrimp, Sprint, etc., to meet the application needs of different fields.

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China

Contents

one-stop customized industrial manufacturing services