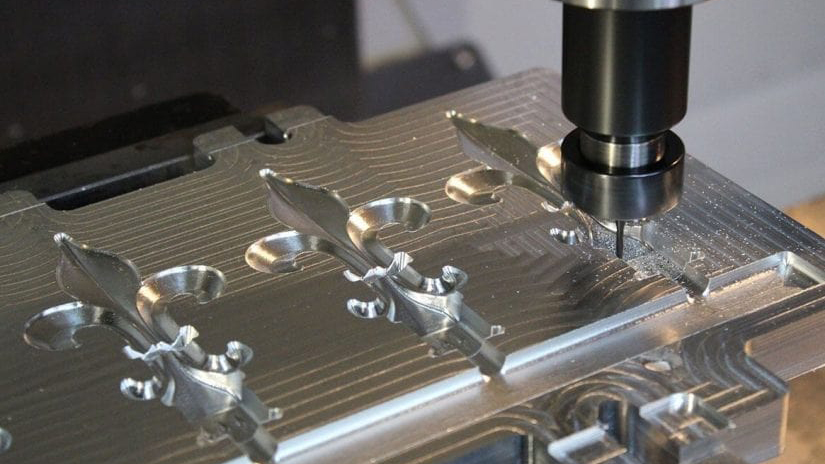

CNC machining

What "preparations" should be done before graphite CNC processing

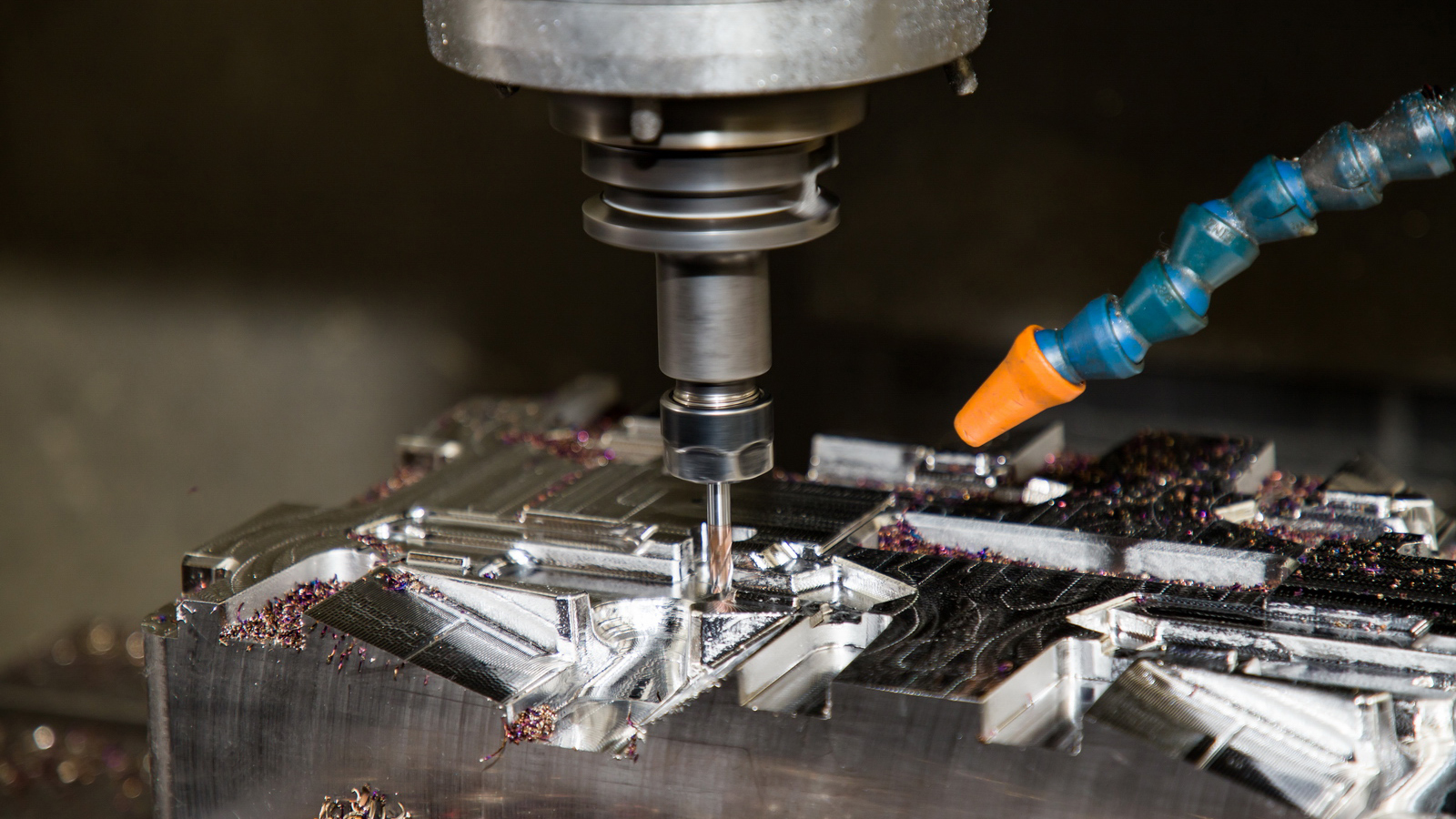

1. select graphite processing equipment

(1) High dust absorption intensity

Graphite processing is very strict with the machine. Powder will not only cause damage to the machine, but also to people. Therefore, suggestions on the dust collection intensity of the equipment are as follows:

1) The frequency converter controls the operation of the dust collector to reduce the vibration source

2) The dust suction port is close to the processing area for rapid dust suction

3) The regular dust blowing design enables the graphite dust deposited in the corner to be blown up and sucked away without staying in the machine

4) The tool magazine door is equipped with an air blowing device to prevent graphite dust from entering the tool magazine. Sticking the tool handle will affect the machining accuracy

(2) Machine tool sealing is very important

The sealing of the tool magazine, including the sealing of the y-axis design, must be very strict. If the sealing of the machine tool is not done well, the equipment will enter dust, and some electronic components will be damaged slowly within 3 months. It is recommended that the y-axis dust cover be designed in an integrated way to upgrade the protection performance.

(3) Solid guide rail oil is generally required

Graphite equipment generally uses solid guide rail oil. The reason why the guide rail oil of graphite still drips oil is that the oil will precipitate after a long time, resulting in waste oil. The waste oil will also slowly drip into graphite or the machine. It is recommended that:

1) Once the guide rail oil drops on the graphite surface, the material will be destroyed;

2) Drip oil recovery device is used to regularly suck oil and recover waste oil.

2、 What problems will be encountered in graphite CNC machining and how to solve them

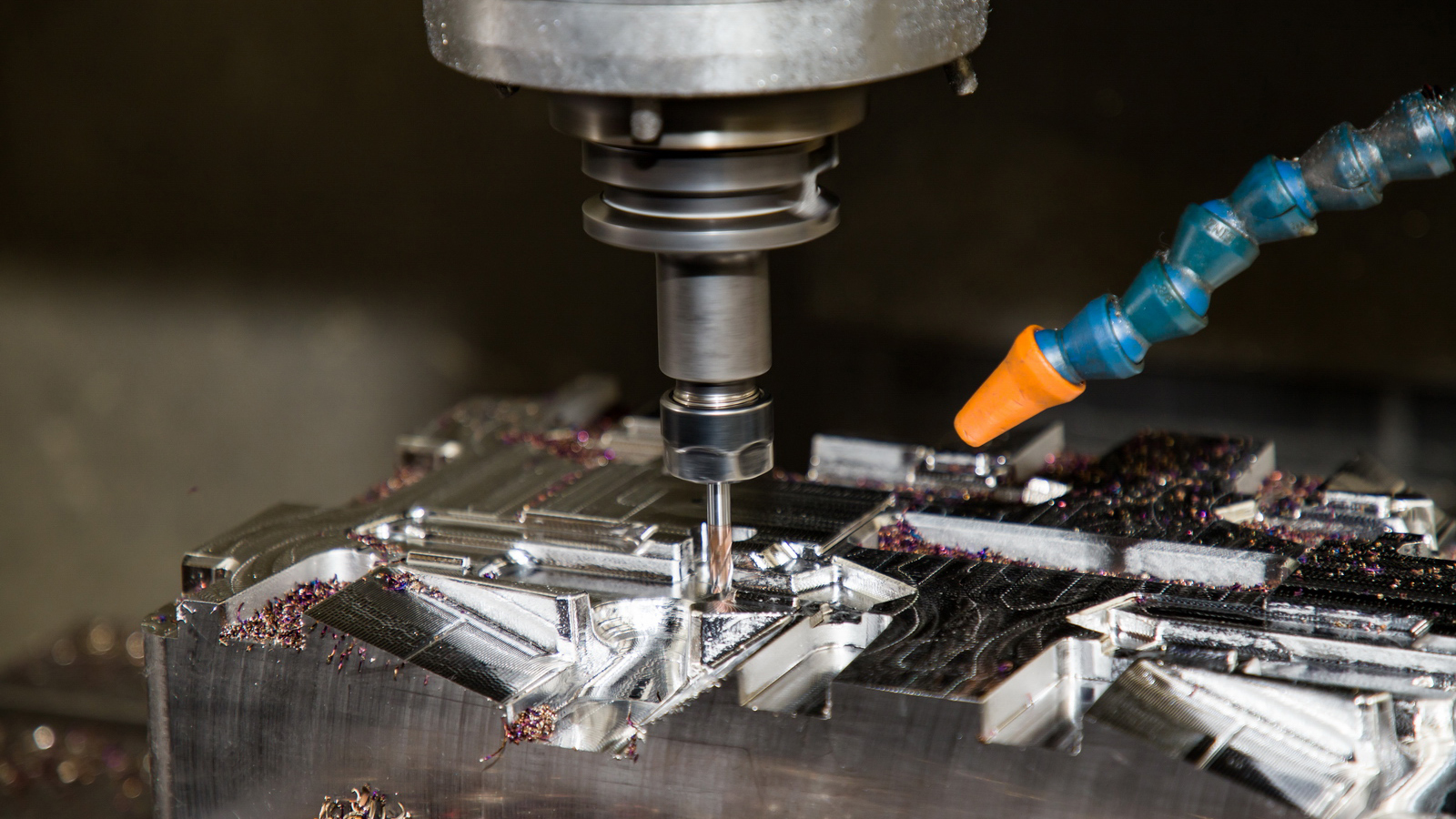

1. cutter line problem

1) Tool problem: it is recommended to use high-quality tools as much as possible. At present, the material and coating formula of cutting tools should be imported. The material and coating of domestic cutting tools are still under further study.

2) Post processing: a special post-processing program that cooperates with the CNC system.

2. dark lines

Machine tools and cutting tools will affect the accuracy and produce dark lines.

1) System problem: the system setting needs to be adjusted. Select the "high precision repair" mode to cooperate with the special post-processing of the system;

2) Tool feeding mode: it is recommended that the two axes move at the same time, rather than the three axes move at the same time. Generally, three axes are used to move at the same time at 45 °. If the three axes move at the same time, the effect is not so good, and it is easy to produce knife marks.

Mastars Industries CO., LTD

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210690

Mobile: +86 181 0029 4997

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China