- [Sport and Lifestyle]Sport and Lifestyle21 Mar,2022

- Mastars has more than 20 years of professional forging experience, focusing on hot forging, warm forging, cold forging, 3D forging technology for non-ferrous metals such as copper, aluminum alloy, stainless steel, etc., and has one-stop customized service of mold development, mold manufacturing, product manufacturing and surface treatment.

- [Household Appliances Industry]Household Appliances Industry21 Dec,2021

- Mastars produced injection molds and tooling and decorative paint finishes for domestic and business-machine enclosures. Mastars's experience covers a wide range of domestic and commercial applications, from vacuum air to digital printers.

- [Cases]Case Study on Vacuum Die Casting of a Certain Automobile Brake Housing: Technica24 Nov,2025

- The successful implementation of this technical solution highlights the significant potential of vacuum die casting and precision temperature control in enhancing the performance and yield of zinc alloy die castings, providing an important reference for the production of similarly demanding components.

- [Cases]3D Printing: A Technological Revolution Restructuring Production Logic Across In17 Nov,2025

- 3D printing utilizes digital model-driven layer-by-layer deposition to break the geometric constraints and efficiency bottlenecks of traditional subtractive manufacturing, unleashing transformative value across dozens of fields including aerospace, healthcare, and automotive manufacturing.

- [Blog]Driving Innovation: The Transformative Role of Rapid Prototyping Tooling in the17 Nov,2025

- The article provides a detailed examination of specific technologies like Vacuum Casting, Direct Metal Laser Sintering (DMLS) for conformal-cooled molds, and sand casting for powertrain components.

- [Cases]3D Printing in the Rapid Prototyping of an Intake Manifold for New engine10 Nov,2025

- This case study provides a detailed analysis of how a leading automotive manufacturer (OEM) utilized additive manufacturing technology for the rapid prototyping of an intake manifold in a new high-performance turbocharged engine project.

- [Blog]The underlying logic of management: the SQDCM five priorities10 Nov,2025

- Today, we'll break down a proven logical hierarchy: security, quality, delivery, cost, and personnel/morale/maintenance. This isn't a random order; it's the underlying code for a company's long-term survival.

- [News]Vacuum Casting: Accelerating Innovation in the Automotive Industry with Mastars04 Nov,2025

- While technologies like 3D printing have revolutionized rapid prototyping, Vacuum Castingremains a cornerstone technology for producing high-quality, functional prototypes and small-batch components. This process is indispensable for bridging the gap between a digital design and mass production, especially within the automotive sector.

- [Blog]The Art and Science of Stainless Steel Forging: Precision, Strength, and Applica04 Nov,2025

- Stainless Steel Forging involves the strategic shaping of stainless steel alloys using localized compressive forces, typically delivered by a hammer, press, or die. This process aligns the metal's grain structure, creating a continuous flow that follows the general shape of the component.

- [FAQ]3D Printing Prototyping: definition, process, advantages, applications31 Oct,2025

- Here's a detailed explanation of 3D Printing Prototyping, covering its definition, process, advantages, applications.Rapid prototyping with 3D printing is the process of quickly creating physical models from digital designs to test ideas and improve them faster

- [FAQ]The Glossary of Vacuum Casting Terminology31 Oct,2025

- Here is a detailed guide to the professional terminology associated with Vacuum Casting (also known as Urethane Casting or Polyurethane Casting)

- [FAQ]Comprehensive introduction to Sheet Metal Prototype manufacturing terminology31 Oct,2025

- Here is a detailed guide to the professional terminology associated with Sheet Metal Prototyping and manufacturing.This glossary is organized by the typical workflow, from design to finished part.

- [FAQ]A detailed introduction to Rapid CNC Prototyping31 Oct,2025

- Rapid CNC Machining refers to the use of Computer Numerical Control (CNC) machining technologies—specifically milling and turning—in an accelerated, highly efficient manner to produce functional prototypes, tooling components, and low-volume production parts in the shortest possible lead time.

- [FAQ]Detailed introduction to Pressure die Casting31 Oct,2025

- Pressure Die Casting is the premier manufacturing method for producing high volumes of complex, high-integrity metal components with exceptional efficiency and precision.

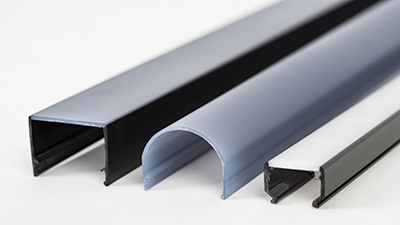

- [FAQ]Plastic Extrusion: A Detailed Overview31 Oct,2025

- Plastic extrusion is the process of melting plastic into a mold through an extruder to create a plastic part.

- [FAQ]Metal Injection Molding (MIM): Professional Terminology31 Oct,2025

- Here is a detailed guide to the professional terminology associated with Metal Injection Molding (MIM). This glossary is organized to follow the sequential steps of the MIM process.